Label paper conveying mechanism

A technology of conveying mechanism and label paper, which is applied in the directions of transportation and packaging, object separation, object supply, etc. It can solve the problems of affecting the efficiency of the process, reducing the life of the equipment, complex structure, etc., to improve efficiency, prolong life, and high safety Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

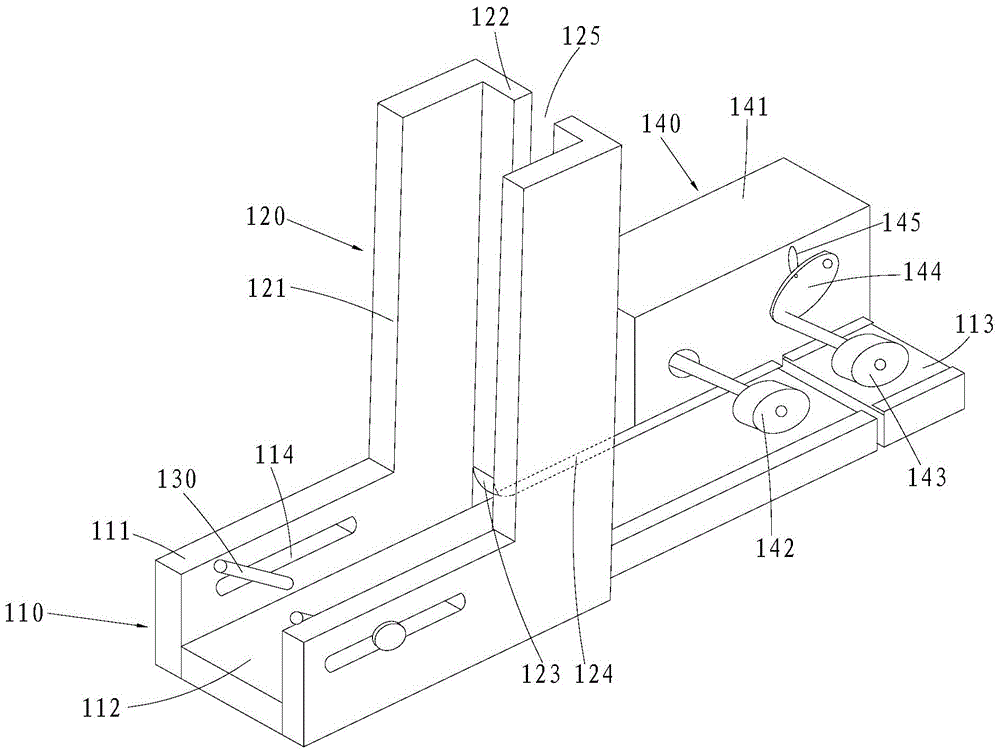

[0015] Such as figure 1 As shown, the label paper conveying mechanism includes a conveying channel 110 , a paper feeding channel 120 , a lower holder 130 and a paper output unit 140 .

[0016] Both sides of the rear portion of the conveying passage 110 have first side barriers 111 for fixing the paper feeding passage 120 .

[0017] The conveying channel 110 is provided with a belt conveyor belt 112 and a conveying roller 113 that can convey label paper in a straight line in the same plane. The conveying roller 113 is adjacent to the front side of the belt conveyor belt 112, and the conveying direction of both is from back to front. ;

[0018] The paper feeding path 120 includes two second side baffles 121 and a front baffle 122, the two second side baffles 121 are fixed on the first side baffle 111 of the conveying path 110 obliquely forward, the lower end of the front baffle 122 passes through a The arc-shaped extension 123 extends two upper baffles 124 above the two side p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com