Borer having automatic position recoganition function

A technology for drilling machines and drilling tools, applied in portable drilling machines, drilling/drilling equipment, power metering, etc., can solve problems such as increased rotational resistance, spalling, and increased energy consumption during drilling

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

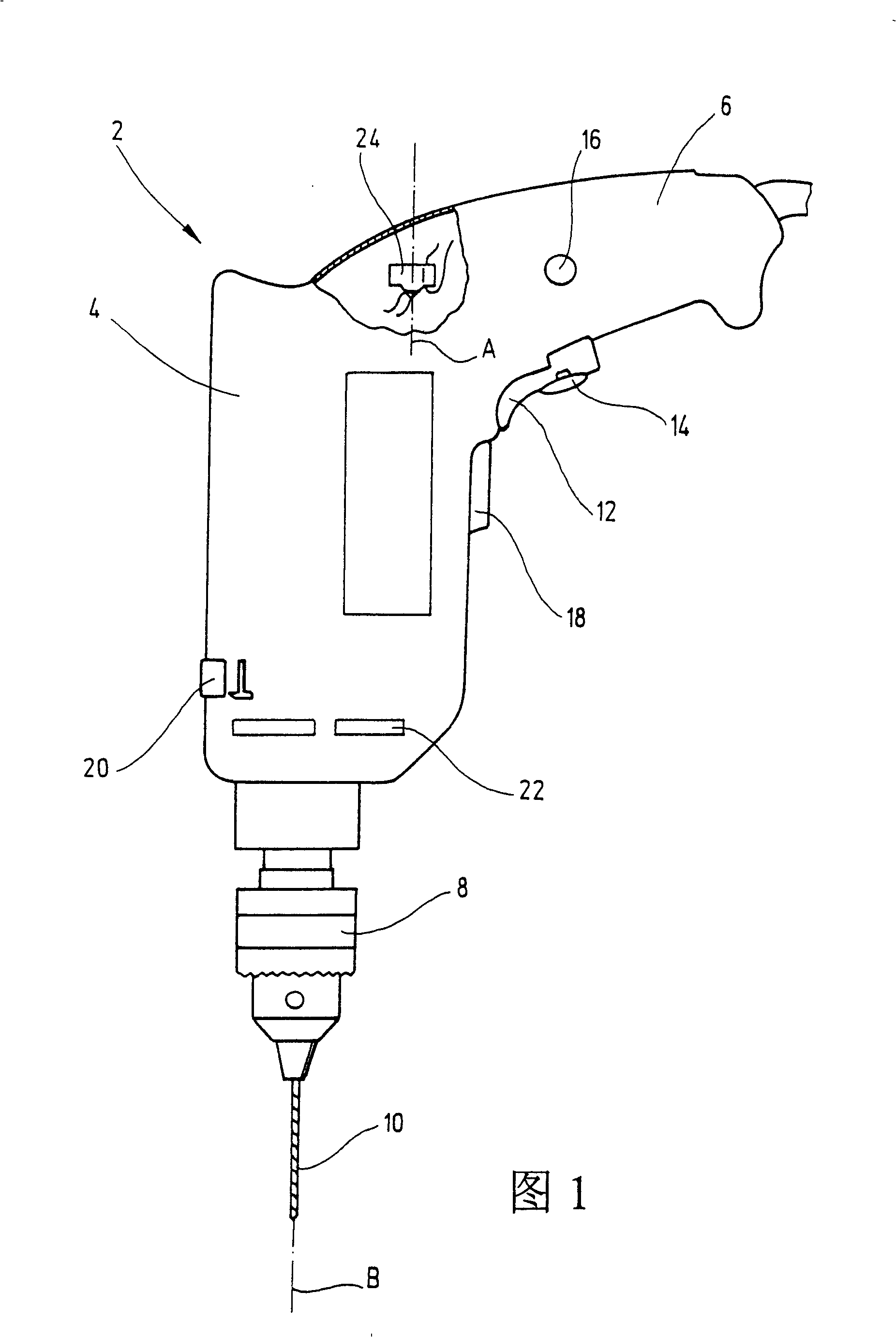

[0017] The percussion drill 2 shown in the accompanying drawings is mainly composed of a housing 4 with a handle 6 and a drill sleeve 8 protruding from the housing 4, which is used to clamp a drill or another Drilling tool 10.

[0018] As common percussion drills on the market, the housing 4 is provided with on the handle 6: an on / off switch 12; A regulating wheel 14 of the rotating speed; a locking button 16 for the continuous operation of the drilling rig and a switch 18 for changing the direction of the drill ferrule 8 . A slide switch 20 is provided on the upper side of the housing 4 for switching from pure drilling operation to percussion drilling operation and vice versa. The housing 4 surrounds a drive motor and a gear (not shown) and is provided with ventilation slots 22 on its sides and top for ventilation of the motor.

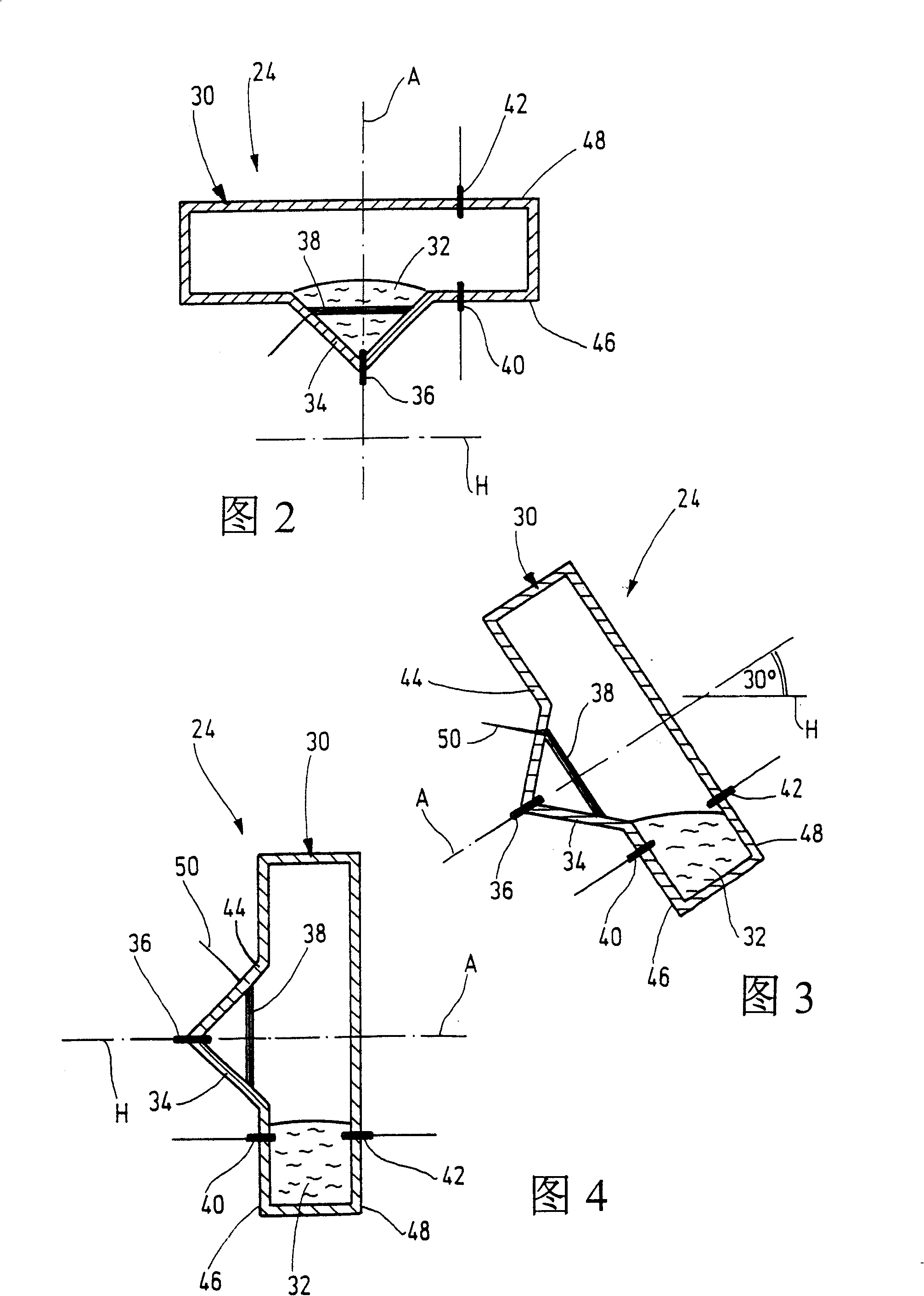

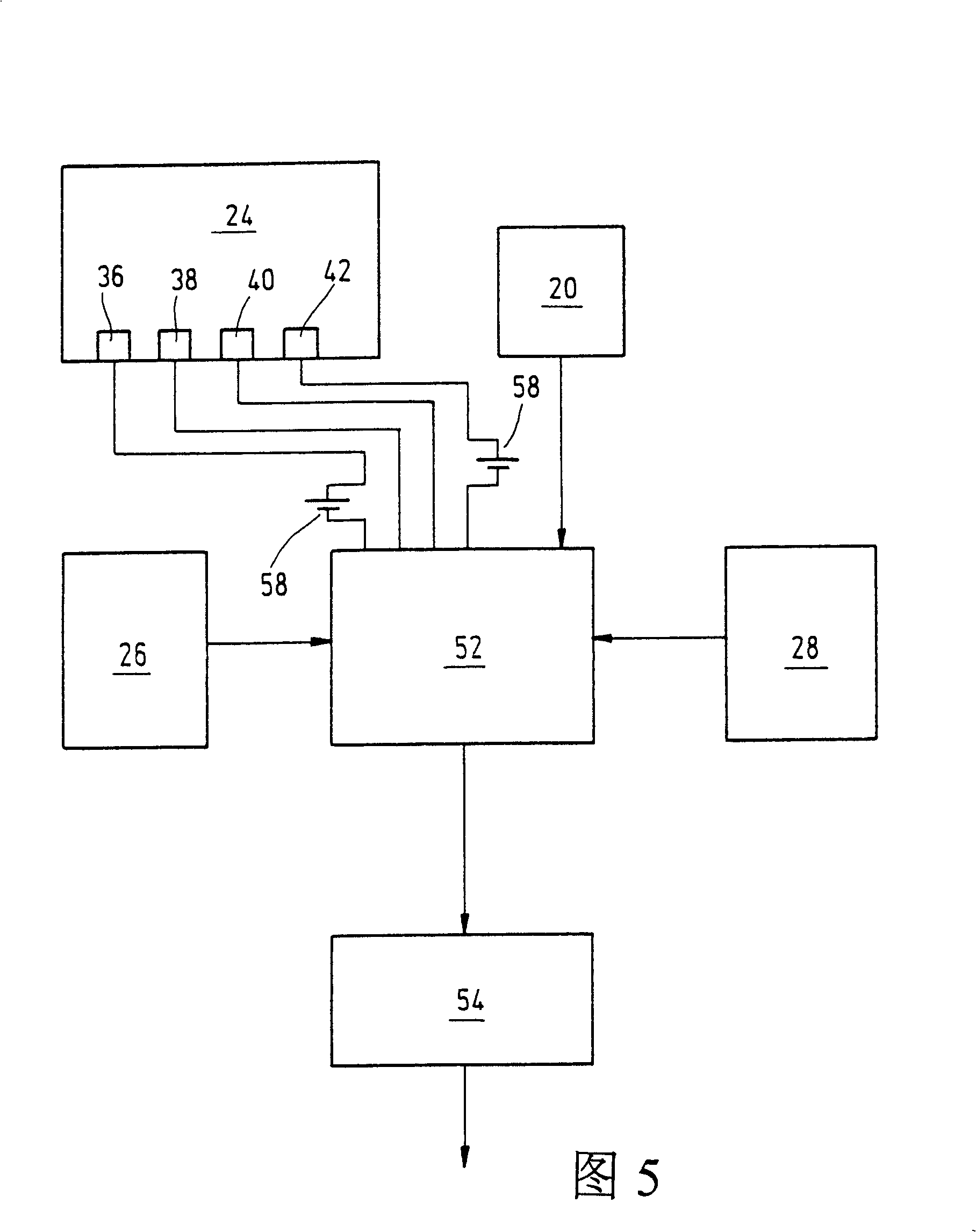

[0019] In addition to the motor and transmission, the housing also encloses: an inclination sensor 24 for sensing the orientation of the drill axi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com