Splashing type pneumatic degassing system

A degassing chamber and degasser technology, applied in the directions of liquid degassing, liquid degassing general layout, liquid degassing adjustment/control, etc. The effect of prolonging the service life, stable operation and easy maintenance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] The technical solution of the present invention will be further described below in conjunction with the accompanying drawings.

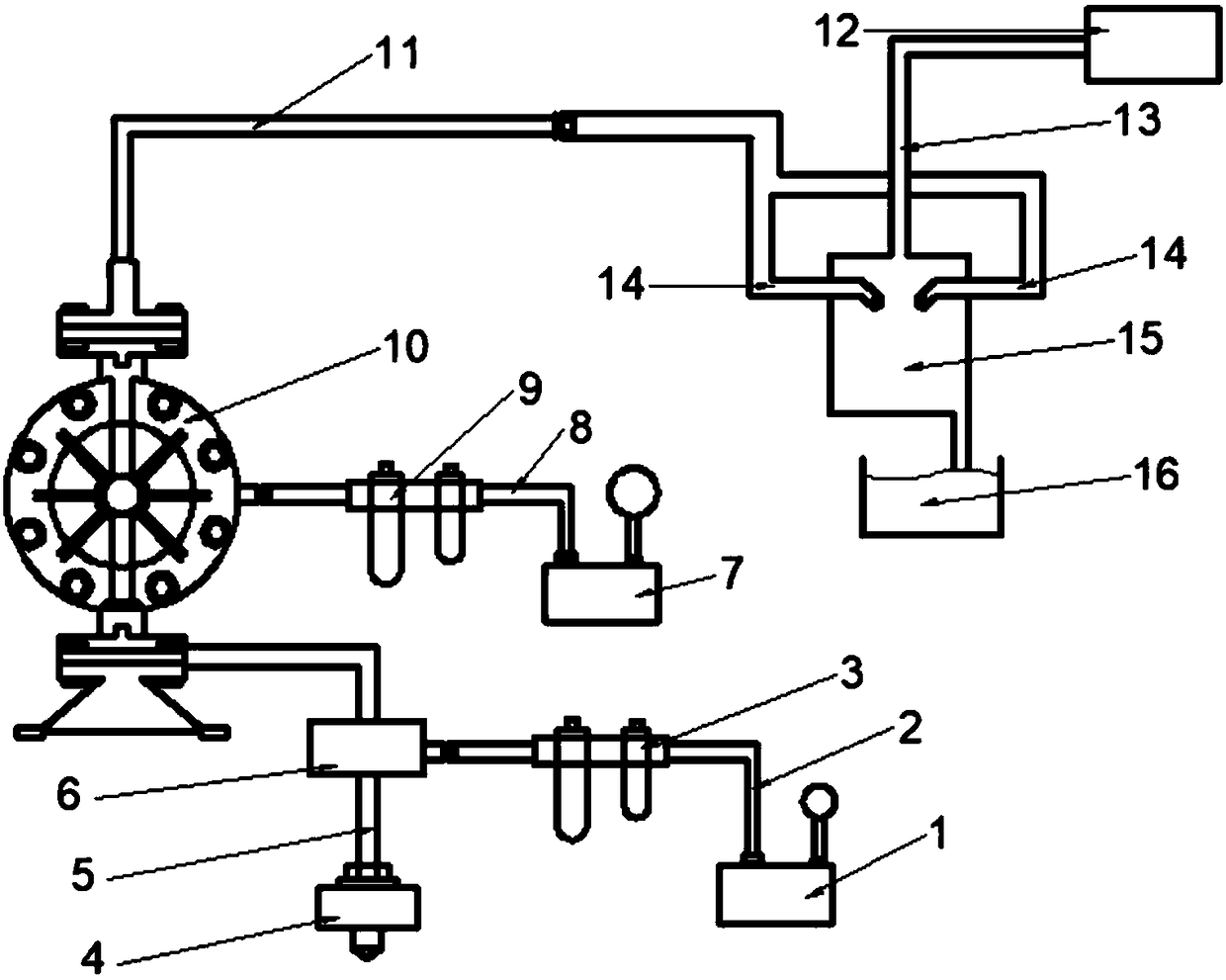

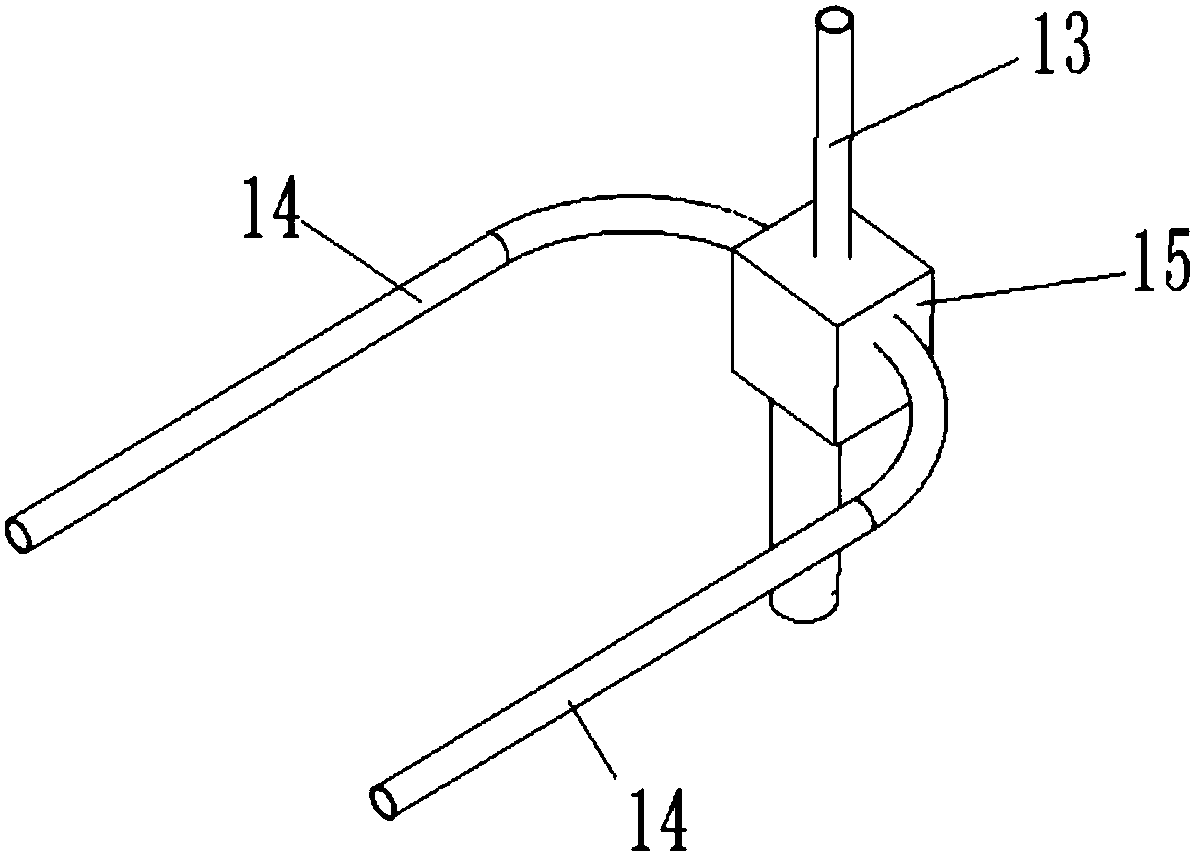

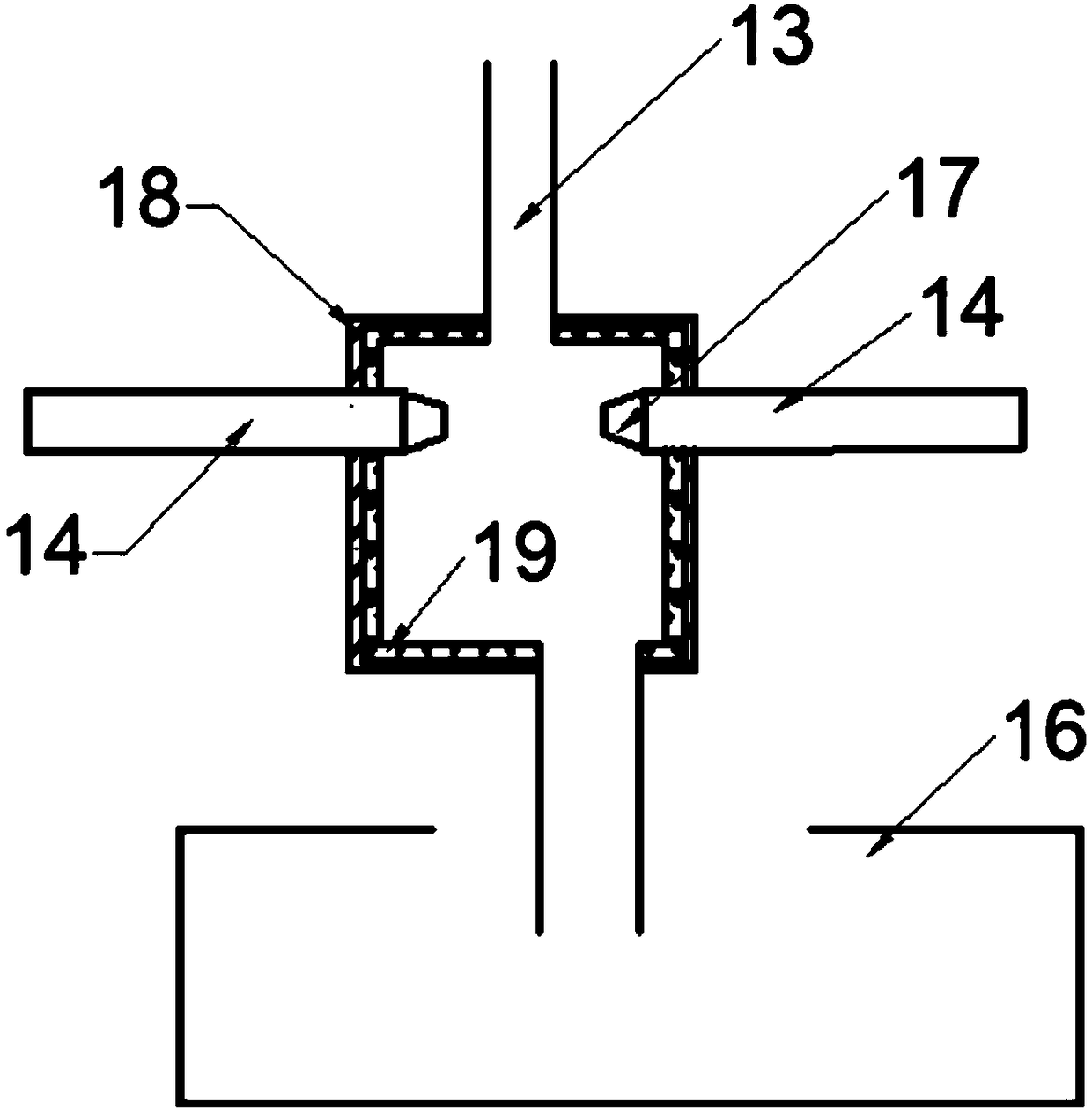

[0022] Such as figure 1 As shown, a splash type pneumatic degassing system includes a pneumatic diaphragm pump 10, and the pneumatic diaphragm pump 10 is also connected with a PLC automatic control system to realize the automatic operation of the pump and the automatic emptying of the pump when the pump is stopped; the pneumatic diaphragm pump The inlet end of 10 is connected with the mud suction port 4 through the A pipeline 5, and the pneumatic anti-blocking device 6 is arranged on the A pipeline 5, the lower end of the pneumatic anti-blocking device 6 enters the mud, and the upper end discharges the mud. The mud pipeline is blocked. When the pipeline is blocked, open the side port and pass in high-pressure gas to unblock it. The side port of the pneumatic anti-blocking device 6 is connected to the first air compressor 1 through the B pipeli...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com