Stabilizer for rotating inner barrel in drum-type washing machine

A drum washing machine and stabilizing device technology, which is applied to washing devices, other washing machines, textiles and papermaking, etc., can solve problems such as deformation of the joint between the bearing and the outer tub, aggravate bearing eccentricity, damage, etc., so as to prolong the service life, prevent eccentricity, The effect of reducing noise

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

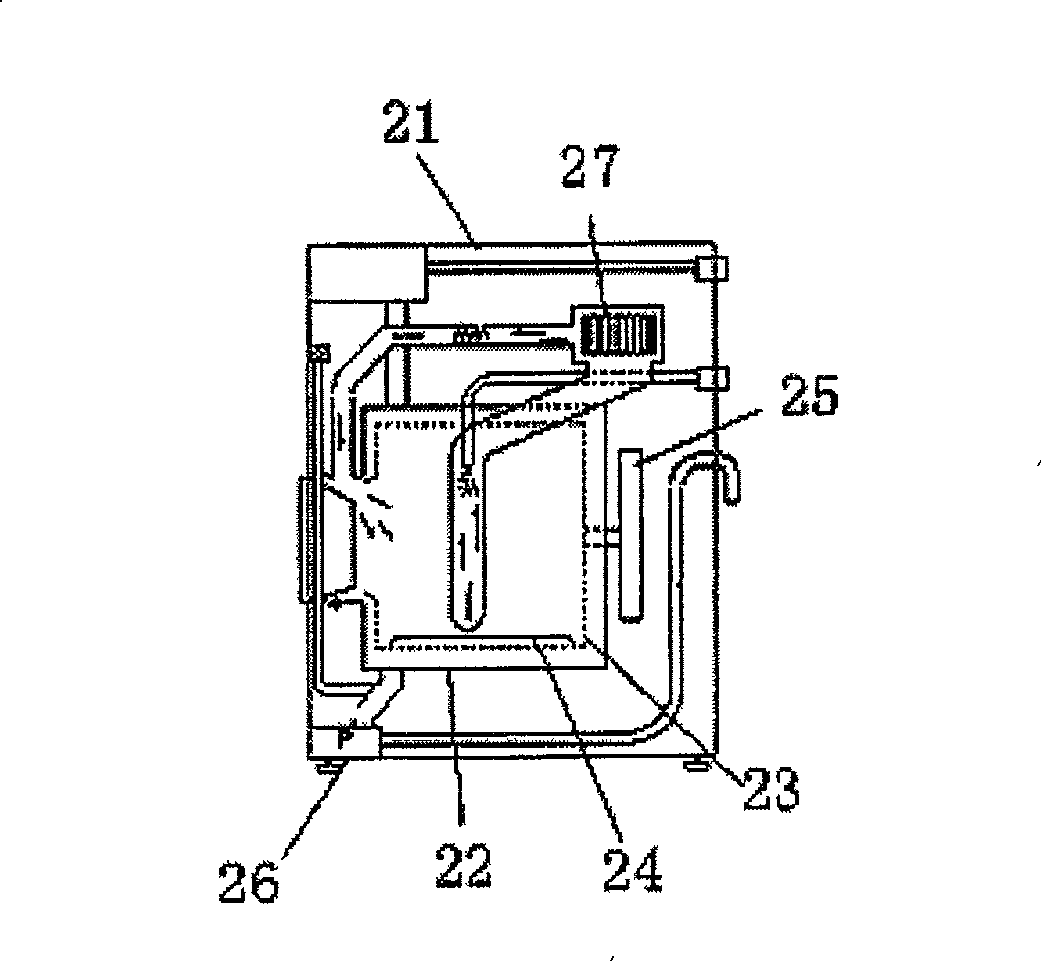

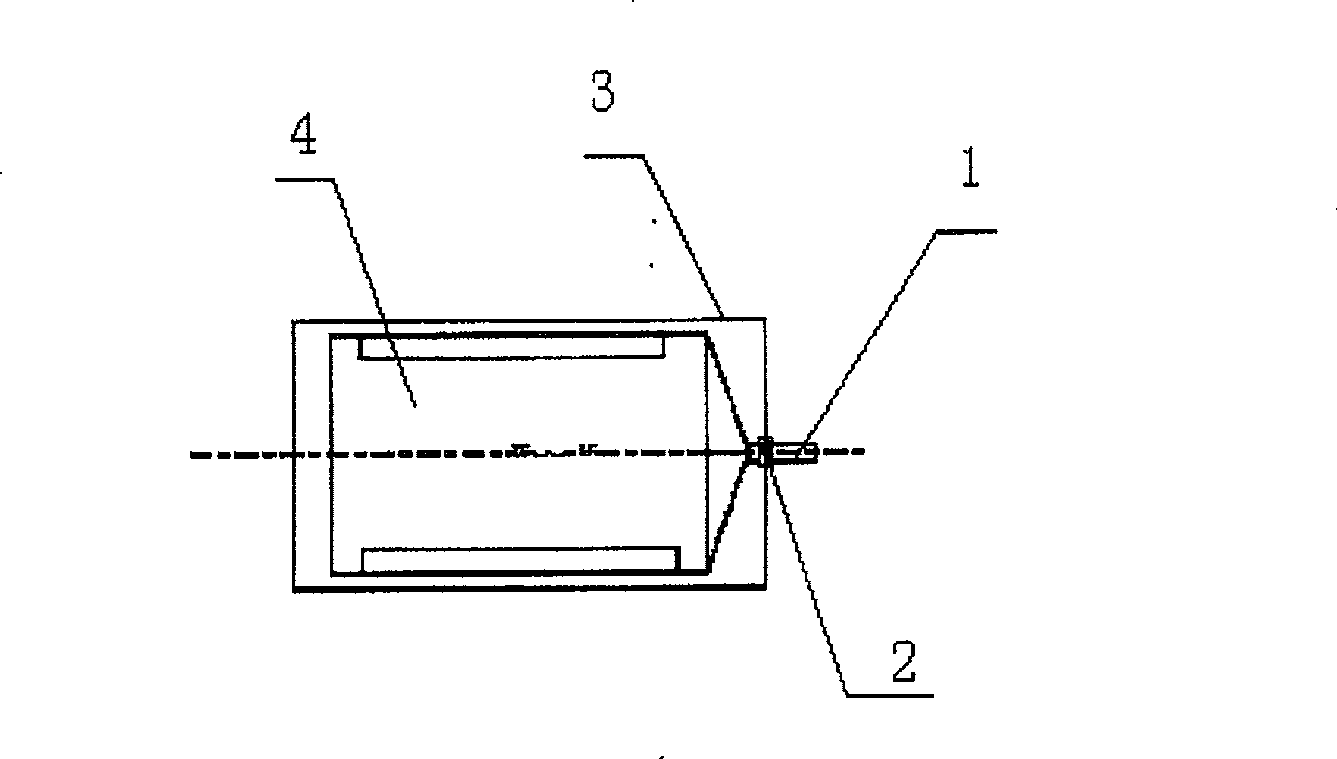

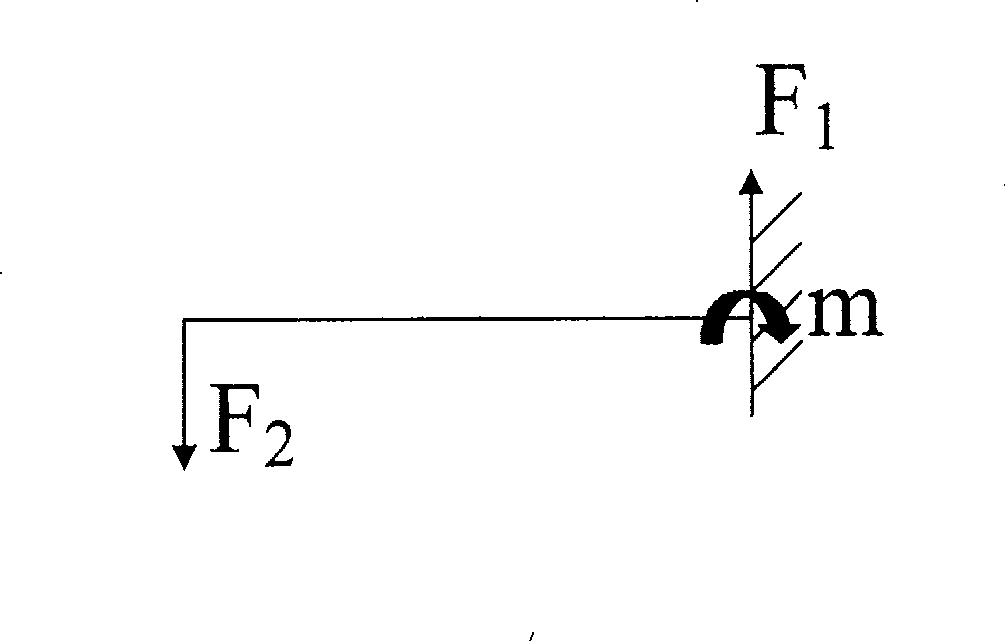

[0017] A device for stabilizing the operation of the inner tub in the drum washing machine according to the present invention, comprising a connecting shaft 1 connected to the washing machine motor 25 to make the inner tub 4 run, the connecting shaft 1 is installed on the outer tub 3 of the washing machine through a bearing 2, and the bearing 2 is fixed on the washing machine Outer barrel 3 on. A group of three supporting shafts 5 for supporting the inner tub 4 of the washing machine are arranged on the outer tub 3 of the washing machine. There is track 6, and track 6 is also arranged on the inner tub of the washing machine and away from one end of motor 25. The position of track 6 corresponds to support shaft 5, and is adapted to support shaft 5 when the inner tub rotates. The three support shafts 5 are evenly distributed on the circumference of the outer barrel 3 at 120 degrees. The support shaft 5 adopts a smooth bearing structure, and is firmly fixed on the circumference ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com