Filter structure for the exhaust gas from an internal combustion engine

A filter and component technology, which is applied in the field of particulate filters for internal combustion engine exhaust gas, can solve problems such as leakage structure, loss of filter structure binding force, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

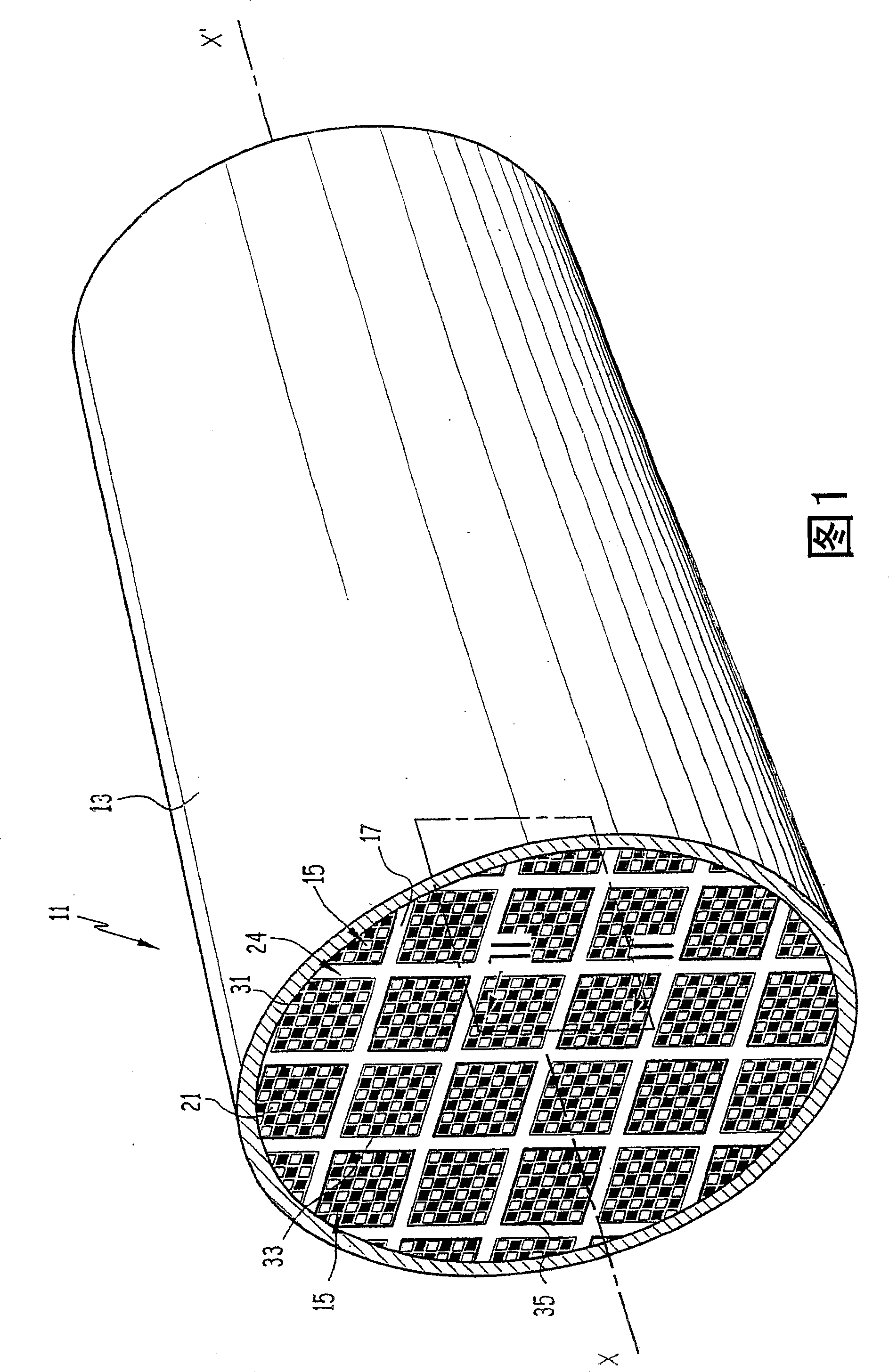

[0040] A particulate filter 11 shown in FIG. 1 is placed in an exhaust pipe 13 for discharging exhaust gas from a diesel engine of an automobile, only a part of which is shown.

[0041] The exhaust pipe 13 extends beyond the particulate filter 11 and defines a passage along which the exhaust gas flows.

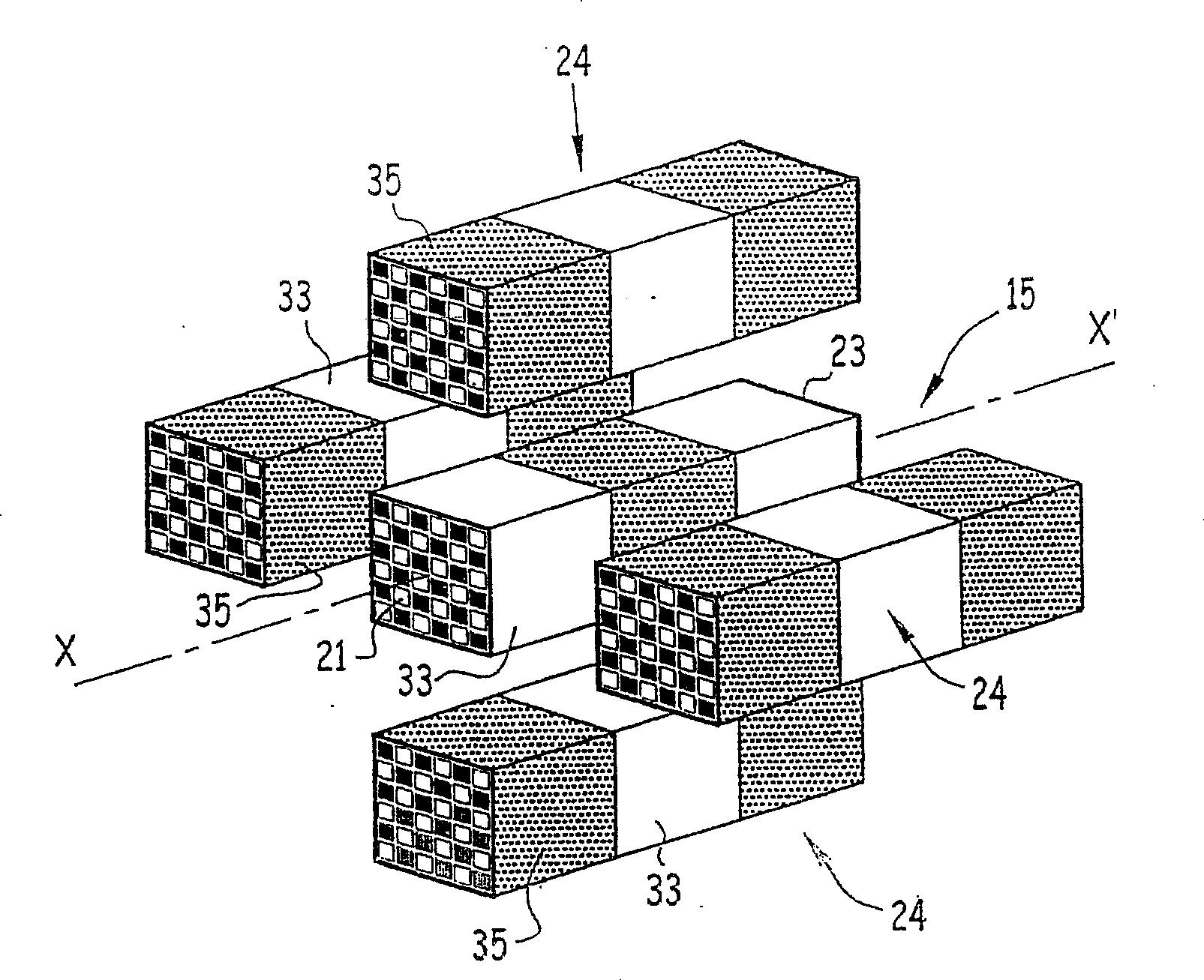

[0042] The particle filter 11 extends along the longitudinal exhaust gas flow direction XX'. It comprises a plurality of filter blocks 15 interconnected by connections 17 .

[0043] Each filter block 15 is substantially in the shape of an elongated rectangular parallelepiped extending in the longitudinal direction XX'.

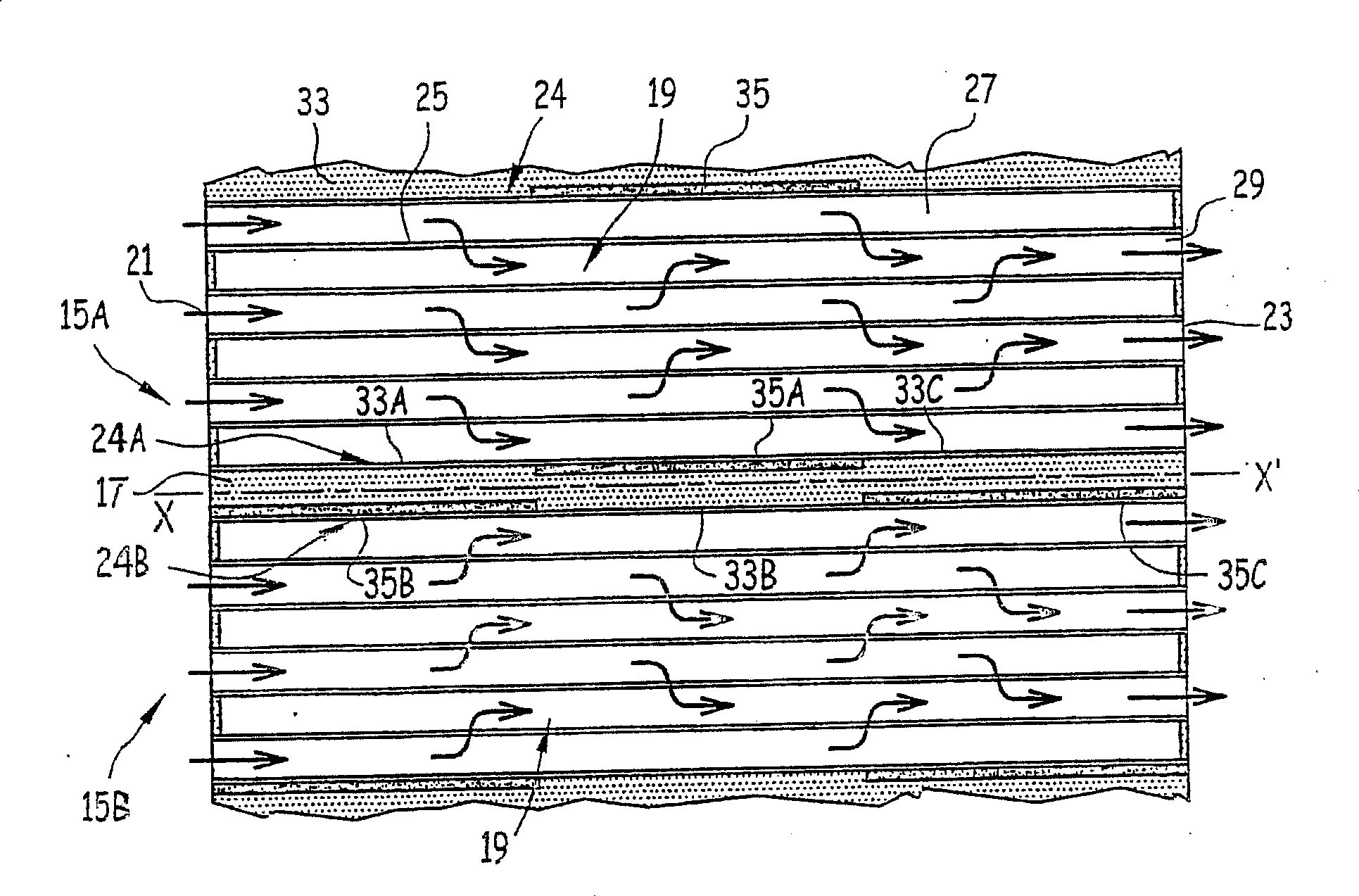

[0044] Such as figure 2 As shown, each filter block 15A, 15B includes a porous filter structure 19, an intake face 21 for receiving exhaust to be filtered, an exhaust face 23 for discharging filtered exhaust, and at least four side 24.

[0045] The porous filter structure 19 is made of monolithic filter material, in particular ceramics (cordierite or silic...

PUM

| Property | Measurement | Unit |

|---|---|---|

| elastic modulus | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com