Fast spoil disposal slope protection and ecological recovery open-pit mining technology

A technology for ecological restoration and open-pit mine, which is applied in the mining of open-pit mines, earthwork drilling, special mining, etc. It can solve the problems of the combination of the final slope treatment, the disturbance of the ground environment by the rock and soil, the loss of life and property, etc. The effect of waste rock transportation distance, environmental protection and transportation cost reduction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

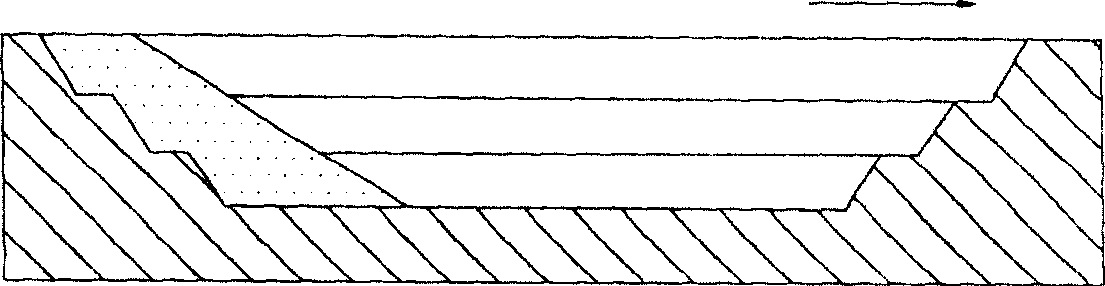

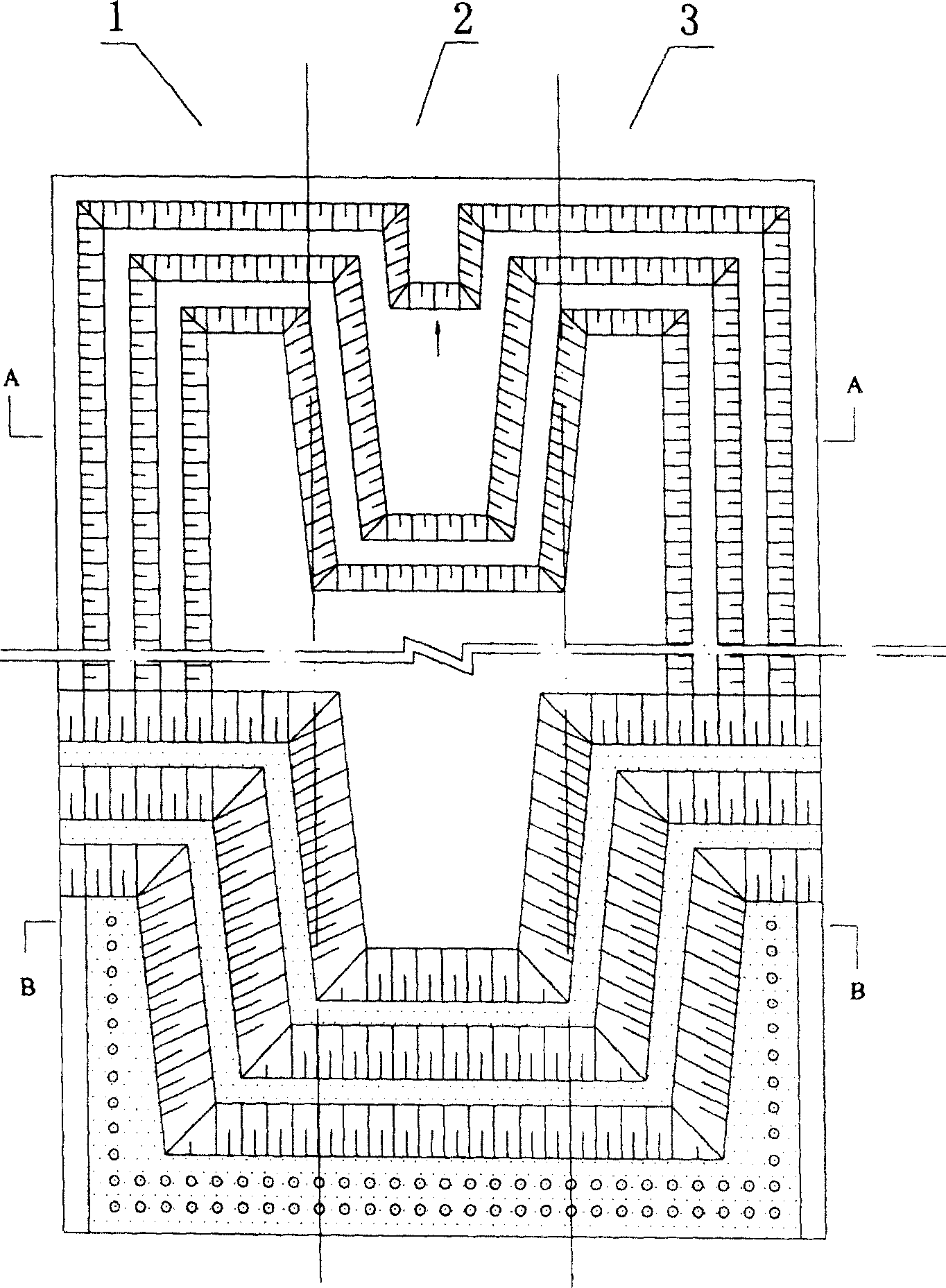

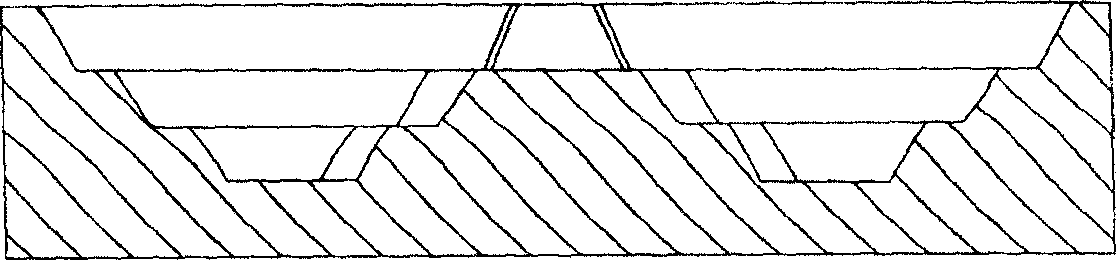

[0027] Such as figure 2 , image 3 , Figure 4 As shown, the open-pit mining process of rapid soil slope protection and ecological restoration includes the following steps:

[0028] (1) Use conventional methods to strip the waste rock at one end or the middle of the ore body, discharge the waste rock to the outer dump site, and mine the stripped ore body to form a minimum size a (generally 50- 100 m) of the initial stripping face 4 (such as Figure 5 , Image 6 , Figure 7 shown);

[0029] (2) In the direction of mining and stripping, the stripping area is divided into left side area 1, middle area 2 and right side area 3 (such as Figure 8 shown), under the condition of meeting the minimum size required by the stripping operation, divide each zone into 2-1000 segments, such as Figure 8 As shown, every advance of 100-200 meters is a subsection, starting from the initial mining and stripping working face 4 as the first subsection 5;

[0030] (3) Firstly carry out the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com