A method of extruding cut tobacco into cigarette pipes and a cut tobacco extruder thereof

A technology for shredded tobacco and paper cigarettes is applied in the field of shredded tobacco extruders, which can solve the problems of large volume, high cost and heavy weight of electric shredded tobacco extruders, and achieve the effects of reducing weight, volume and simple operation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

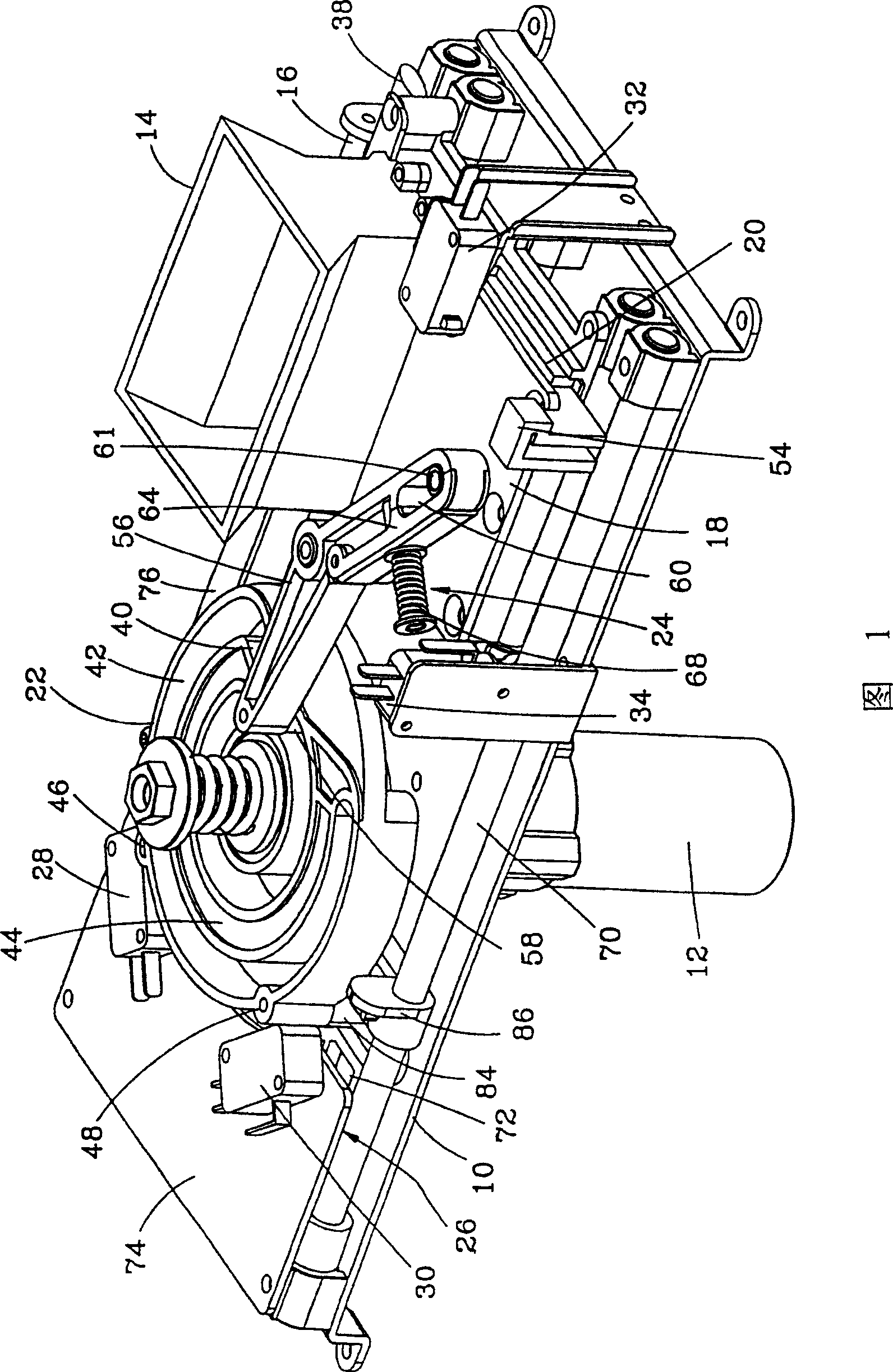

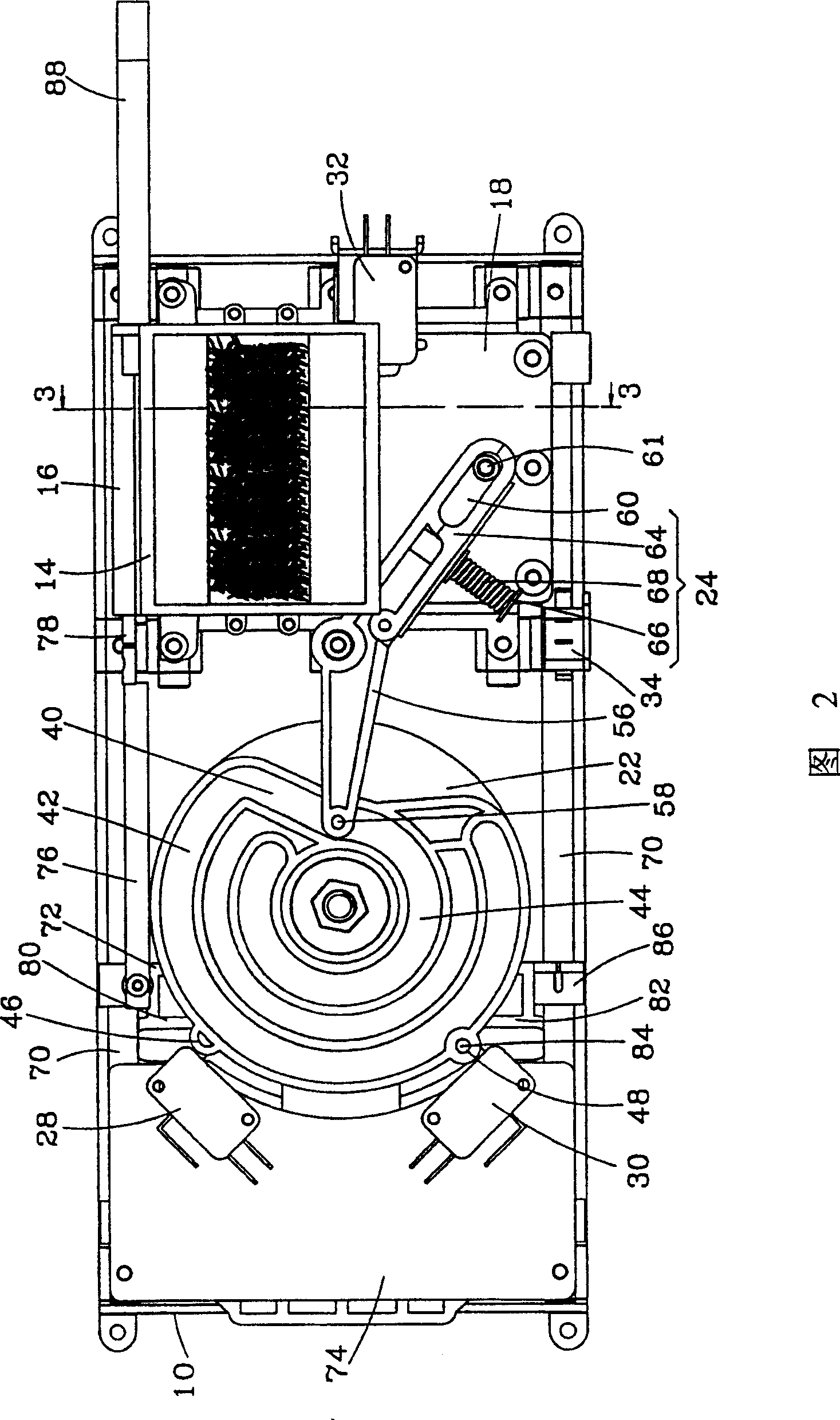

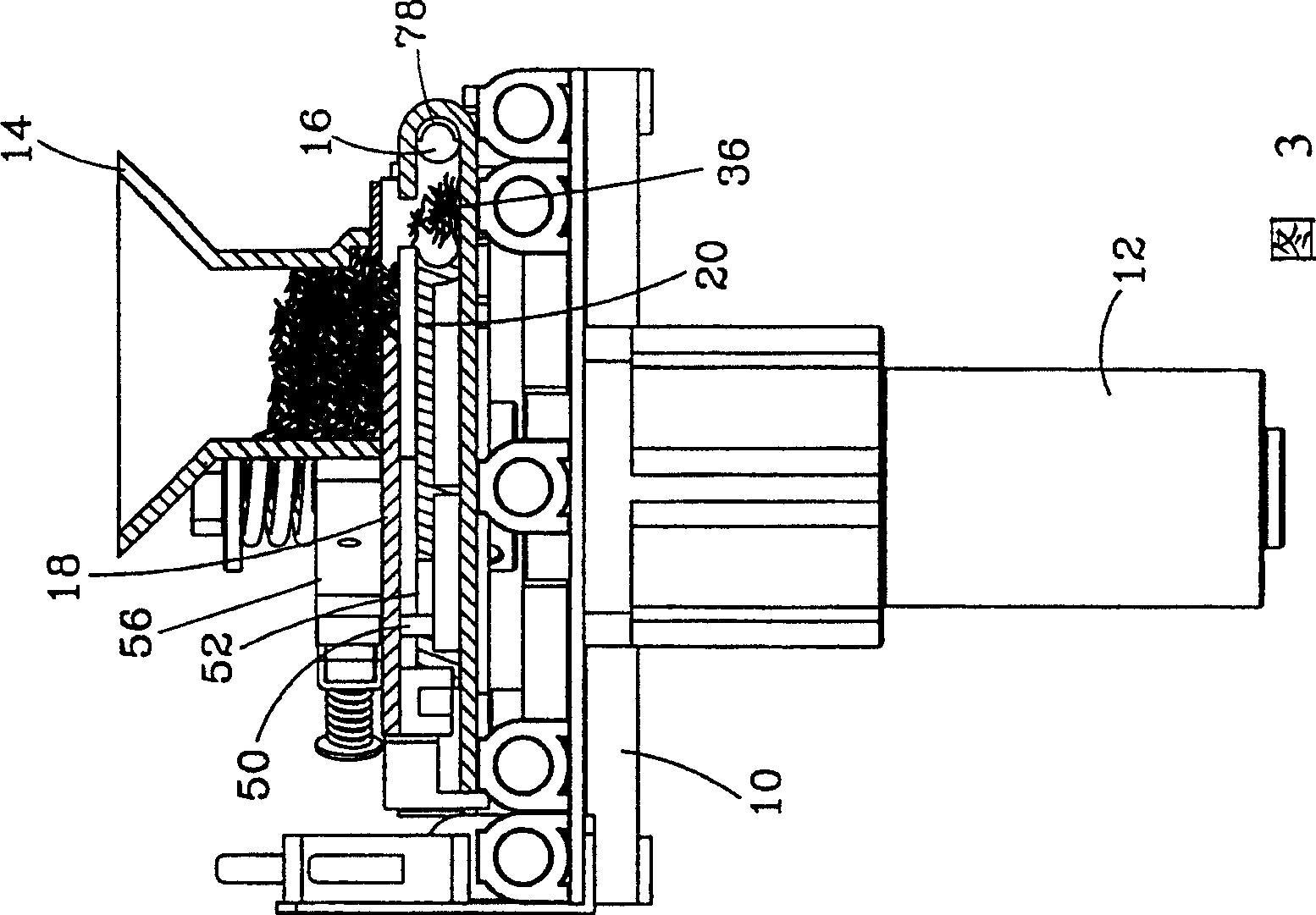

[0024] The implementation steps of the present invention will be described in detail below, and the structure and characteristics of the shredded tobacco extruder provided by the present invention will be described with reference to the accompanying drawings.

[0025] As shown in Figure 1, the tobacco extruder provided by a preferred embodiment of the present invention mainly includes: a base 10, on which a motor 12, a funnel 14, a pressurized chamber 16, a cutter 18, A pressurizing block 20 , a driver 22 , a pressure detector 24 and a pusher 26 .

[0026] A first switch 28 , a second switch 30 , a third switch 32 , a fourth switch 34 and a processor (not shown) are disposed on the base 10 . The processor is connected to each switch and the motor 12, and controls the operation of the motor 12 through the signals sent from each switch. The motor 12 is disposed on the bottom side of the base 10 and connected to the driving element 22 disposed on the top side of the base 10 to d...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com