Locking ring

A technology for snap rings and ring parts, which is applied in the field of snap rings, and can solve the problems of unfavorable insertion and unsatisfactory alignment of journals

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

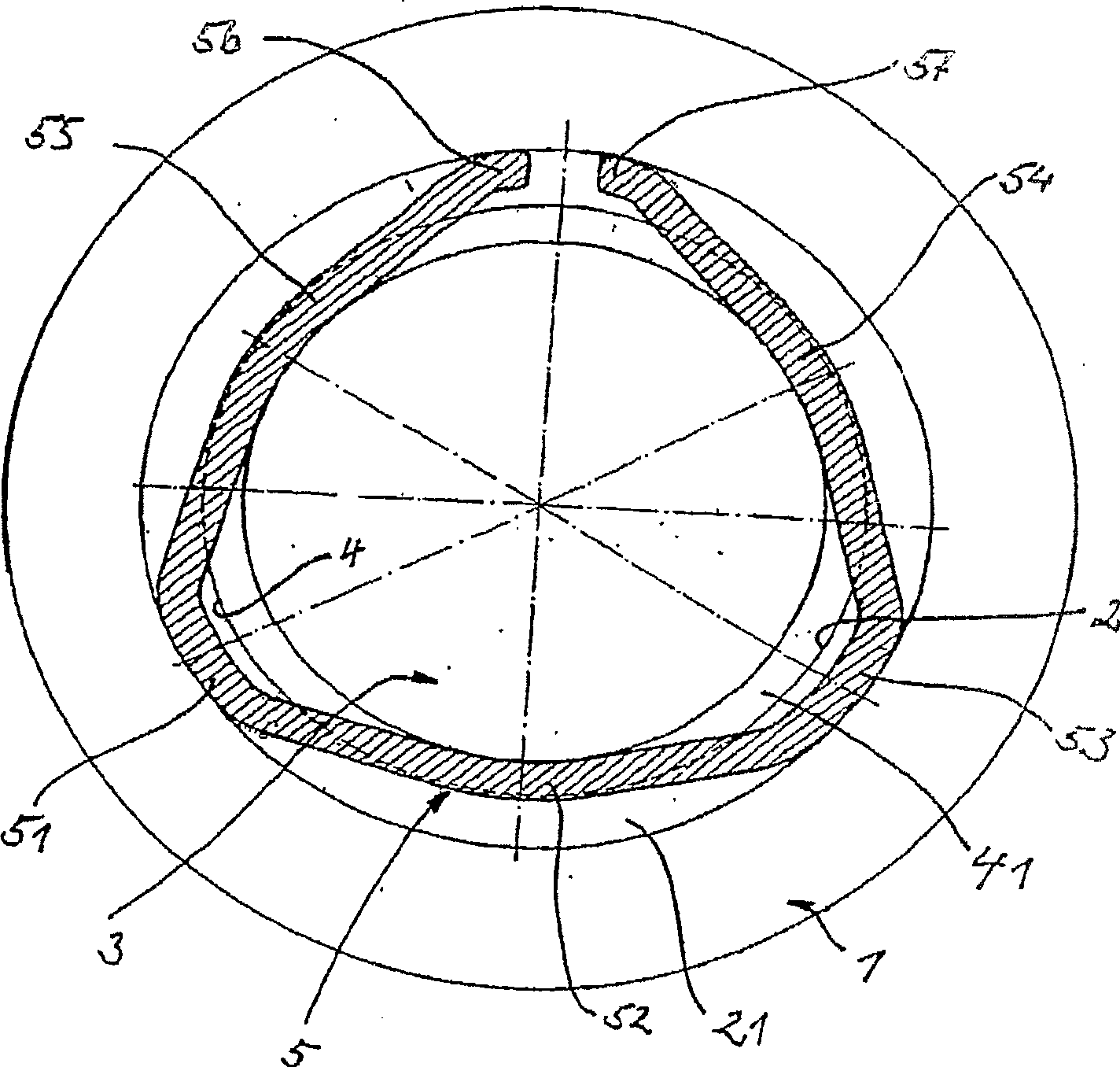

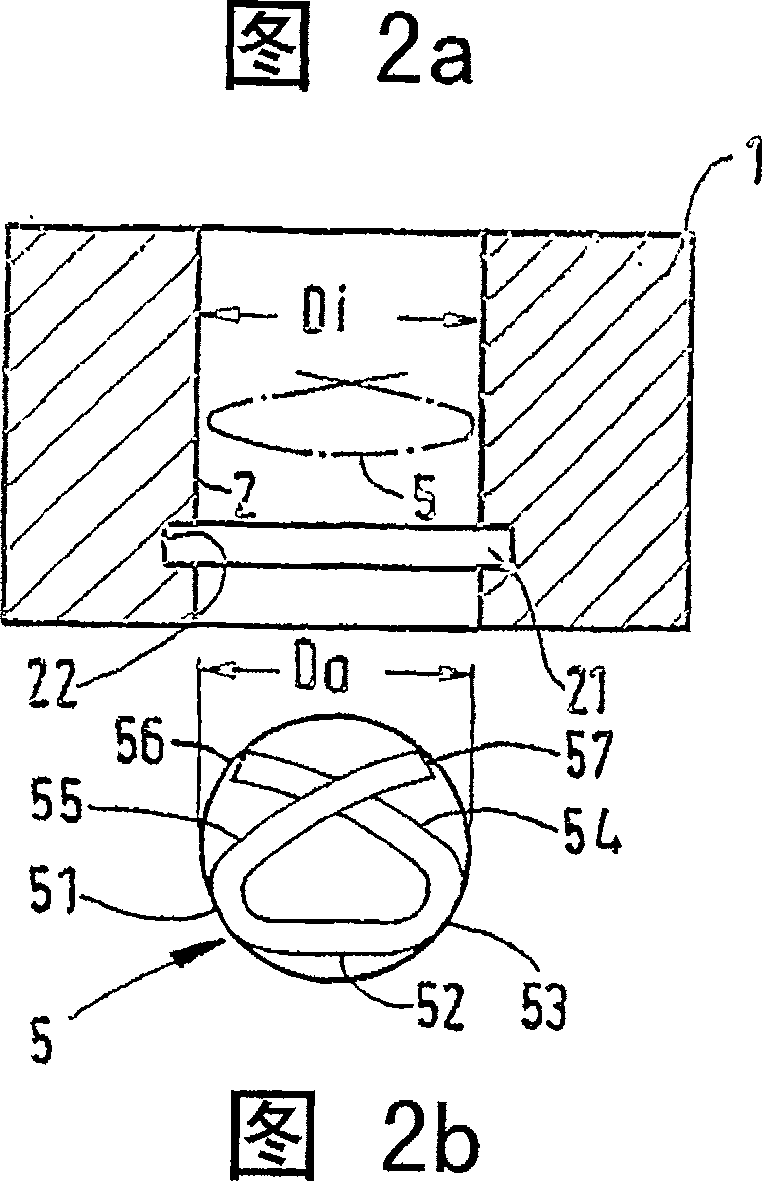

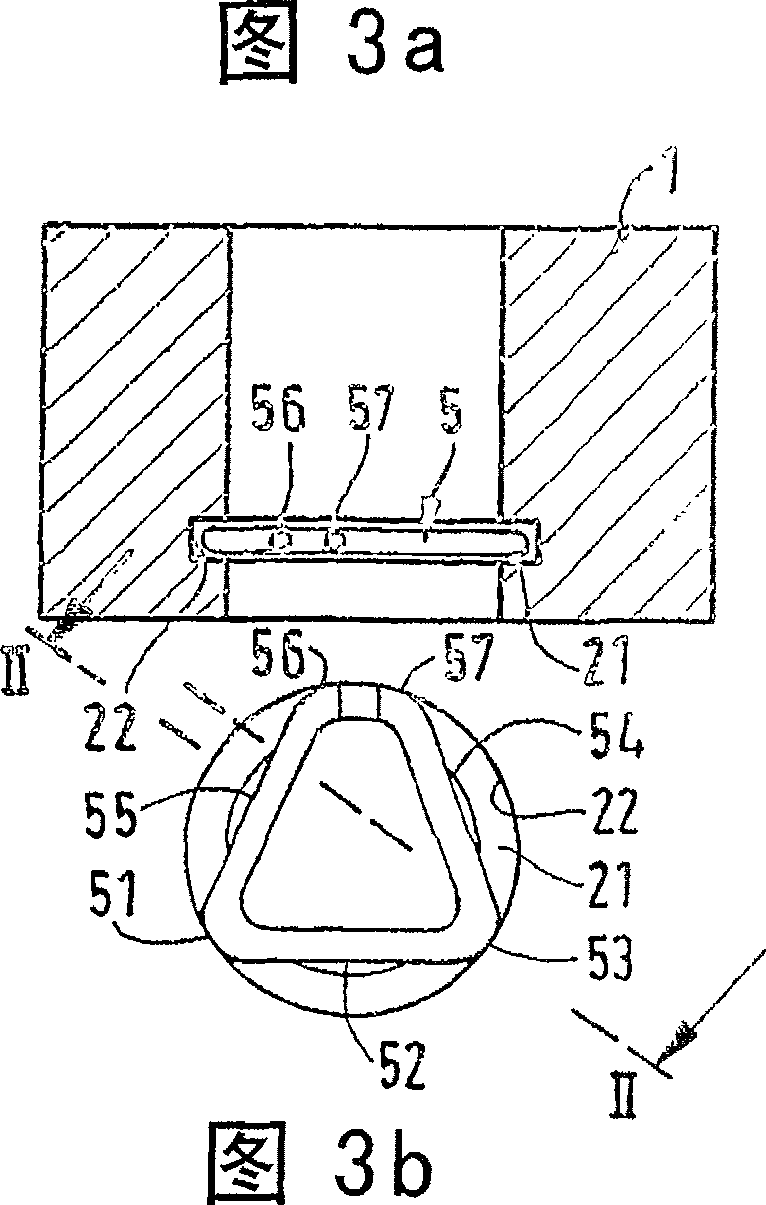

[0018] exist figure 1 Among them, the annular ring part is represented by 1, the shaft part is represented by 3, and the snap ring of the present invention is represented by 5.

[0019] The annular ring part 1 surrounds a circular inner bore 2 in which an annular inner groove 21 is arranged. An annular outer circumferential groove 41 is provided on the outer circumference 4 of the shaft part 3 .

[0020] According to a preferred embodiment, the safety washer 5 basically comprises a base 52 and laterally arranged legs 54, 55 which together have an approximately triangular shape, wherein preferably the legs 54 and 55 The opposite free ends 57 and 58 are spaced apart from each other in the circumferential direction. The base 52 is connected to the leg 54 via a preferably rounded corner region 53 . Accordingly, the base 52 is connected to the leg 55 via a preferably rounded corner region 51 . Particularly preferably, the shape is a substantially equilateral triangle, wherein t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com