Method for improving luminous intensity and thermal stability of nitride red fluorescent powder

A technology of red fluorescent powder and luminous intensity, which is applied in chemical instruments and methods, luminescent materials, energy-saving lighting, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

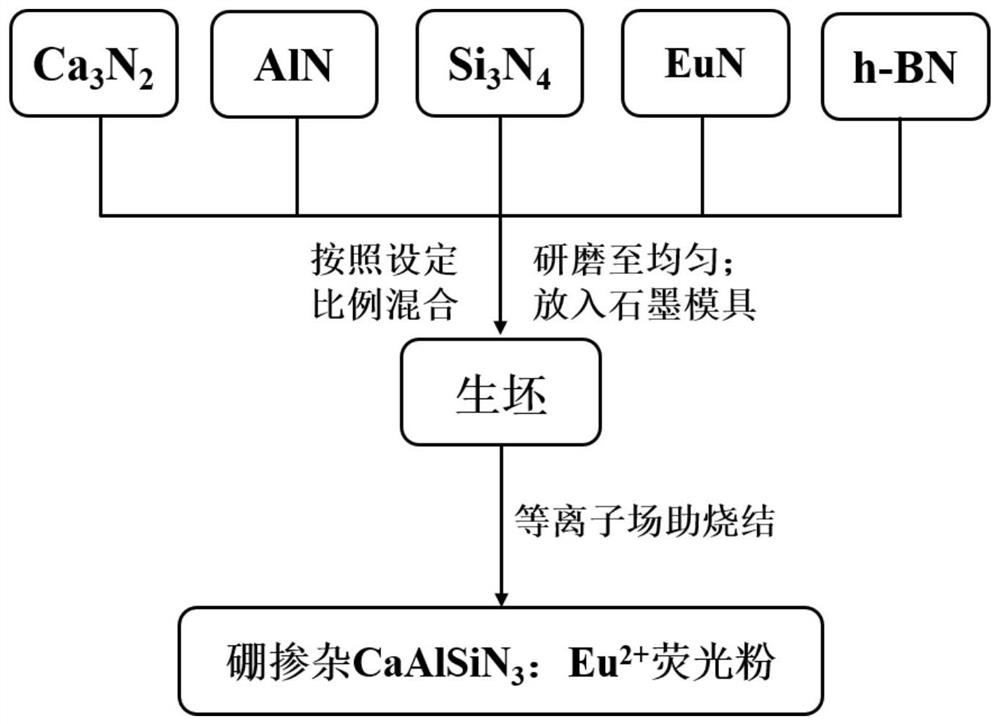

Method used

Image

Examples

Embodiment 1

[0036] Use Ca 3 N 2 , Si 3 N 4 , AlN, EuN as raw material powder. According to Ca 0.99 AlSiN 3 : 0.01Eu 2+ The ratio of each component of the chemical formula is to weigh the raw material, Ca 3 N 2 : 1.631 g, Si 3 N 4 : 1.247 grams, AlN: 1.366 grams, EuN: 0.055 grams. Then, put the raw materials into an agate mortar and grind them manually for more than 15 minutes to get a uniformly mixed powder, then put the powder in a graphite mold, and directly apply the top and bottom of the graphite mold under the vacuum condition of the cavity air pressure Increase the current to make the graphite mold rise from room temperature to 600°C in 3 minutes, then raise the temperature to 1400°C at a heating rate of 180°C / min, keep it warm for 5 minutes, and cool it to room temperature naturally. The obtained product is Ca without boron doping. 0.99 AlSiN 3 : 0.01Eu 2+ Phosphor.

Embodiment 2

[0038] Use Ca 3 N 2 , Si 3 N 4 , AlN, EuN, h-BN as raw material powders. According to Ca 0.99 al 1-x B x SiN 3 :0.01Eu 2+ , x = 0.025 The proportion of each component of the chemical formula weighs the raw material, Ca 3 N 2 : 1.631 g, Si 3 N 4 : 1.247 grams, AlN: 1.332 grams, EuN: 0.055 grams, BN: 0.0207 grams. Then, put the raw materials into an agate mortar and grind them manually for more than 15 minutes to obtain a uniformly mixed powder, then put the powder in a graphite mold, and directly apply the top and bottom of the graphite mold under the vacuum condition of the cavity pressure Increase the current to raise the temperature of the graphite mold from room temperature to 600°C in 3 minutes, then raise the temperature to 1410°C at a rate of 200°C / min, keep it warm for 4 minutes, and cool it down to room temperature naturally. The obtained product is boron-doped Ca 0.99 al 0.975 B 0.025 SiN 3 :0.01Eu 2+ Phosphor.

Embodiment 3

[0040] Use Ca 3 N 2 , Si 3 N 4 , AlN, EuN, h-BN as raw material powders. According to Ca 0.99 al 1-x B x SiN 3 :0.01Eu 2+ , x = 0.05 The proportion of each component of the chemical formula weighs the raw material, Ca 3 N 2 : 1.631 g, Si 3 N 4 : 1.247 grams, AlN: 1.298 grams, EuN: 0.055 grams, BN: 0.0413 grams. Then, put the raw materials into an agate mortar and grind them manually for more than 15 minutes to obtain a uniformly mixed powder, then put the powder in a graphite mold, and directly apply the top and bottom of the graphite mold under the vacuum condition of the cavity pressure Increase the current to raise the graphite mold temperature from room temperature to 600°C in 3 minutes, then raise the temperature to 1430°C at a heating rate of 200°C / min, keep it warm for 3 minutes, and cool it down to room temperature naturally. The obtained product is boron-doped Ca 0.99 al 0.95 B 0.05 SiN 3 :0.01Eu 2+ Phosphor.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com