Reflection preventive film

An anti-reflection and thin-film technology, applied to radiation-absorbing coatings, instruments, synthetic resin layered products, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

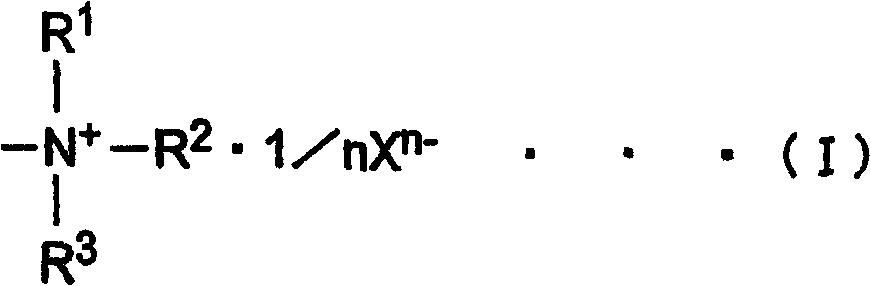

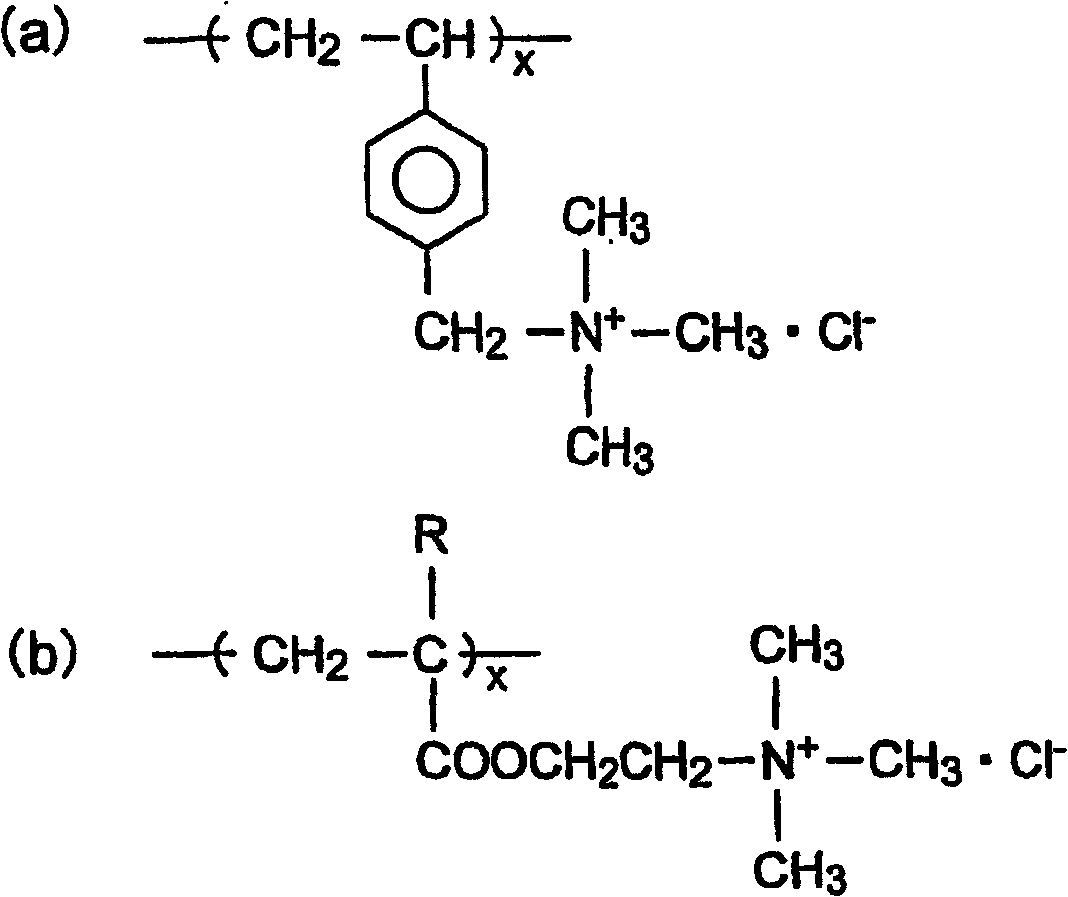

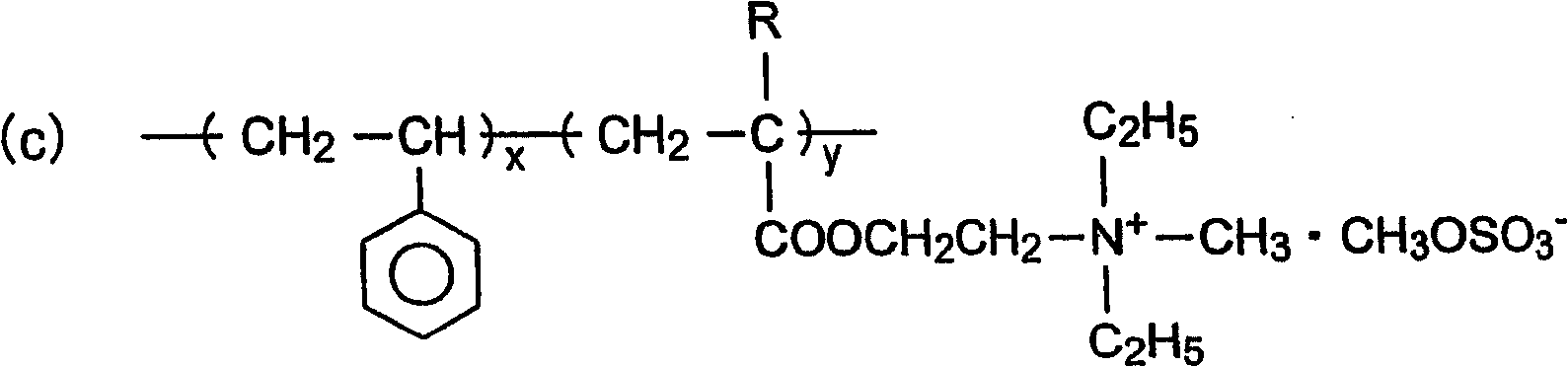

Method used

Image

Examples

Embodiment 1

[0098] (1) Preparation of liquid A (coating liquid for forming a hard coat layer)

[0099] 45 parts by weight of pentaerythritol triacrylate as a trifunctional acrylate monomer [manufactured by Toagosei Co., Ltd., trade name "Aronix M-305", solid content concentration 100%], 0.9 parts by weight of 2 -Methyl-1-[4-(methylthio)phenyl]-2-morpholine-propan-1-one [manufactured by Chiba Specialty Chemicals Co., Ltd., trade name "Irugakuyua 907", solid content concentration 100% ] and 90 parts by weight of a polymer-type cationic antistatic agent having a quaternary ammonium base [manufactured by Colcot, trade name "Colcot NR-121X-9IPA", solid content concentration 9.5% by weight] The mixture was diluted with 1-methoxy-2-propanol to prepare liquid A (coating liquid for forming a hard coat layer) having a solid content concentration of 35% by weight.

[0100] (2) Preparation of liquid B (coating liquid for forming a low refractive index layer)

[0101] 10 parts by weight of pentaeryt...

Embodiment 2

[0108]Except changing the usage amount of antistatic agent " コルコ-ト NR-121X-9IPA " in embodiment 1 (1) to 60 weight parts, carry out in the same way as embodiment 1, prepare antireflection film, the refractive index of hard coat : 1.49

[0109] The physical properties of the thus-prepared antireflection film are shown in Table 1.

Embodiment 3

[0111] Except that the use amount of the MIBK dispersion "ELCOM RT-1002SIV" of porous silica particles in Example 1(2) was changed to 120 parts by weight, the same procedure was carried out as in Example 1 to prepare an antireflection film with a low refractive index Refractive index of layer: 1.40

[0112] The physical properties of the thus-prepared antireflection film are shown in Table 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com