Light-source module and mfg. method

A technology of a light source module and a manufacturing method, which is applied in the direction of cooling/ventilation/heating transformation, discharge lamps, discharge tubes, etc., and can solve problems such as easy deterioration, heat dissipation of the heat dissipation cavity, and temperature rise of the cooling liquid of the heat dissipation cavity.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

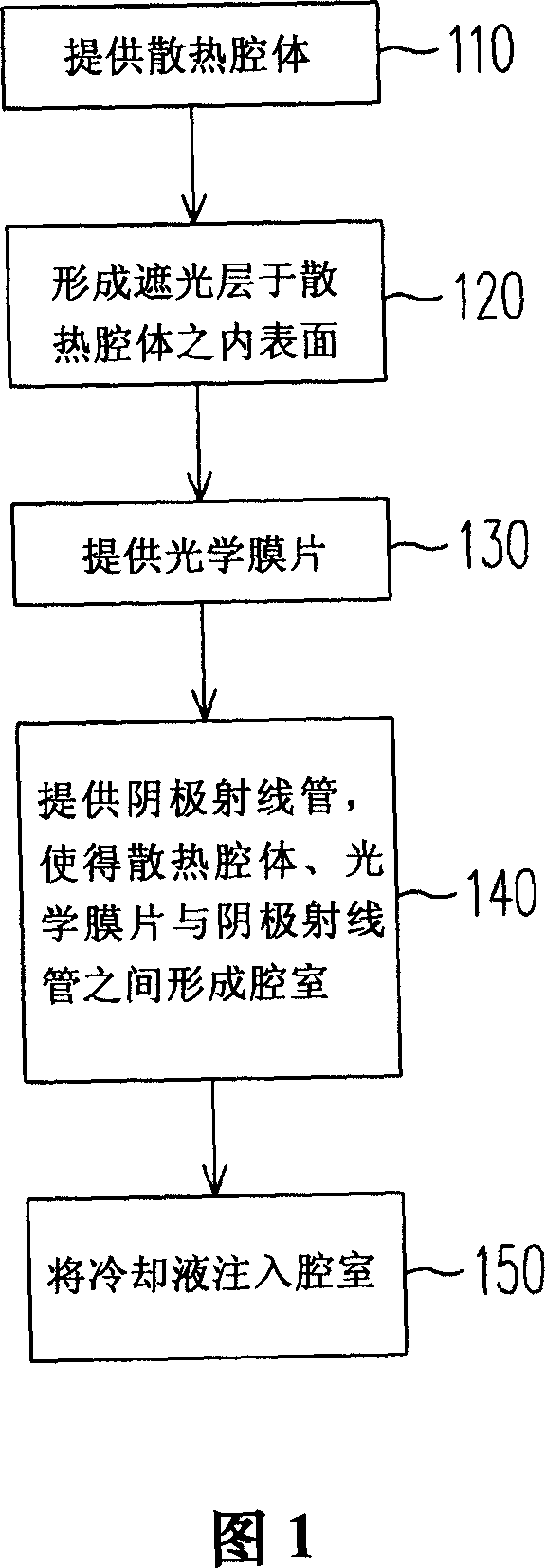

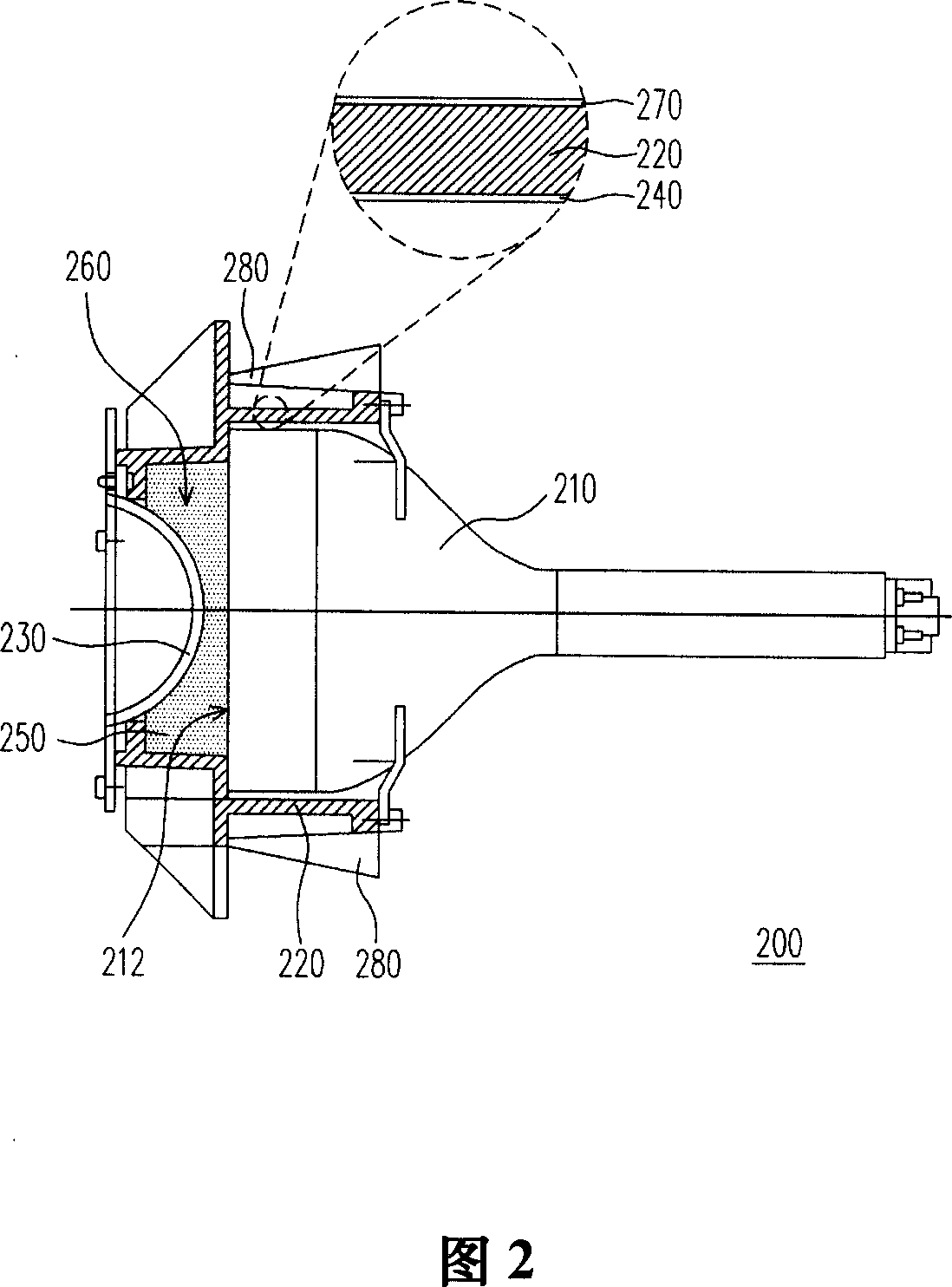

[0045] FIG. 1 is a schematic flowchart of a method for manufacturing a light source module according to a preferred embodiment of the present invention. Please refer to FIG. 1 , the manufacturing method of the light source module is as described in step 110 , providing a heat dissipation cavity with an opening. The material of the cooling chamber is, for example, copper-aluminum alloy, preferably ADC12. Then, as described in step 120 , a light-shielding layer is formed on the inner surface of the heat dissipation cavity, wherein the material of the light-shielding layer is, for example, a dark material. In this embodiment, the method of forming the light-shielding layer is, for example, to firstly provide a material constituting the light-shielding layer, which is, for example, dry powder. In a preferred embodiment, the dry powder is composed of zinc phosphate, for example.

[0046] Based on the above, the dry powder is then adhered to the inner surface of the heat dissipati...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com