Surge protector socket

A technology of surge protection and socket, applied in the direction of contact parts, etc., can solve problems such as low reliability, poor contact, contact melting, etc., and achieve the effects of improving on-off capability, preventing poor contact, and prolonging service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

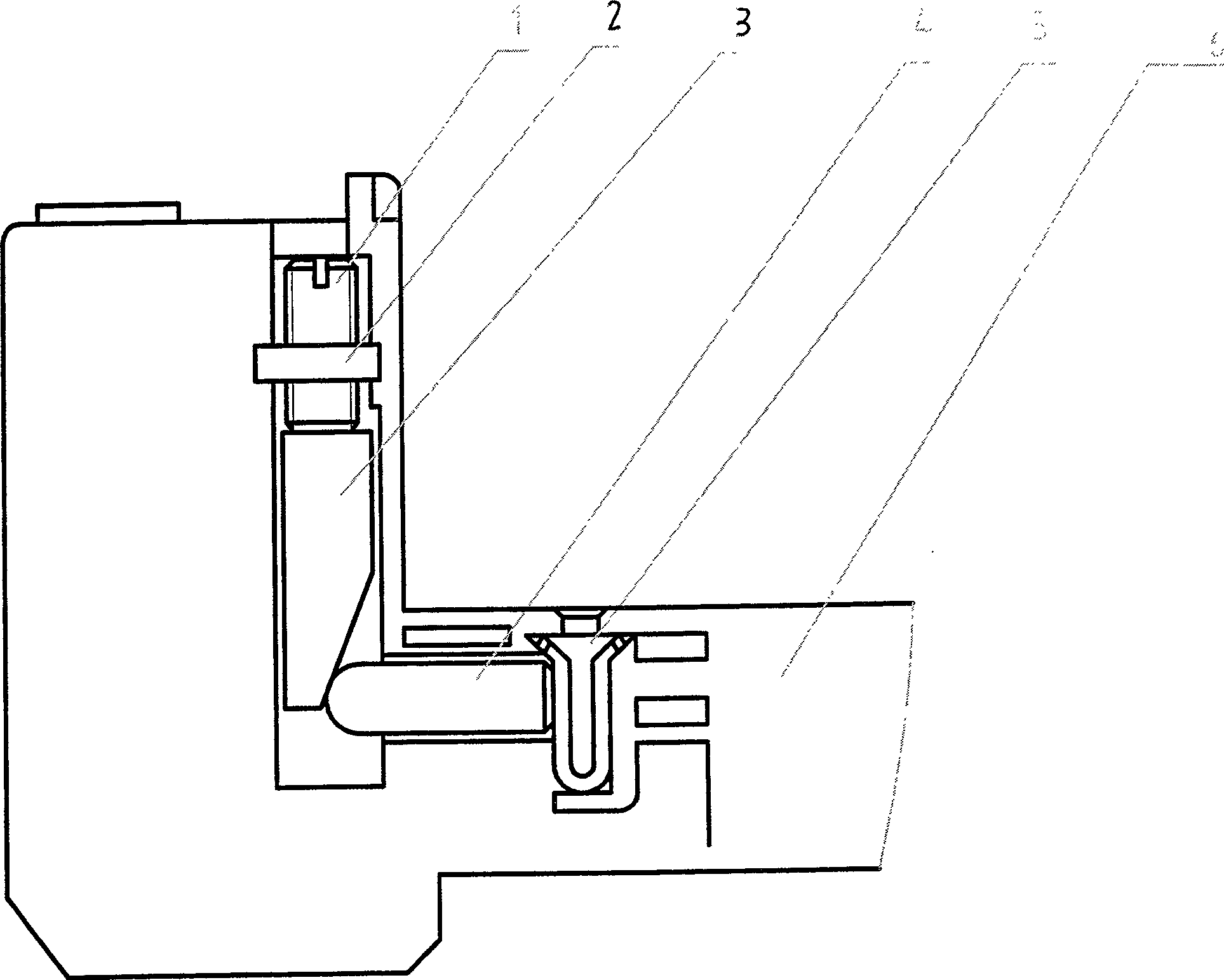

[0010] Below in conjunction with the accompanying drawings, the specific embodiments of the surge protector socket of the present invention are further described in detail:

[0011] A set of L-shaped rails is designed in the surge protector housing (6) in the figure, and the locking and loosening of the lip contacts of the socket can be adjusted from the front. A nut (2) is fixed on the upper end of the L-shaped rail, and the nut (2) Cooperate with an adjusting bolt (1), and one end of the adjusting bolt (1) leans against the leading end of the oblique wedge (3). 3) The ejector rod (4) is matched with the L-shaped track chute in the housing (6), and one end of the ejector rod (4) can press the lip-shaped contact (5) to lock the pin of the plug. Open the adjusting bolt (1), the push rod (4) is separated from the lip contact (5) under the elastic force of the lip contact (5), so that the plug pins can be pulled out and the surge protector can be replaced. plug-in.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com