Method for preparing novel and low toxicity fungicide for crops

A technology for crops and fungicides, applied in the field of preparation of chitooligosaccharide metal complex fungicides, can solve the problems of uneven degradation, long reaction time, etc., and achieve the effects of expanding application range, enhancing bactericidal activity, and low drug efficacy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

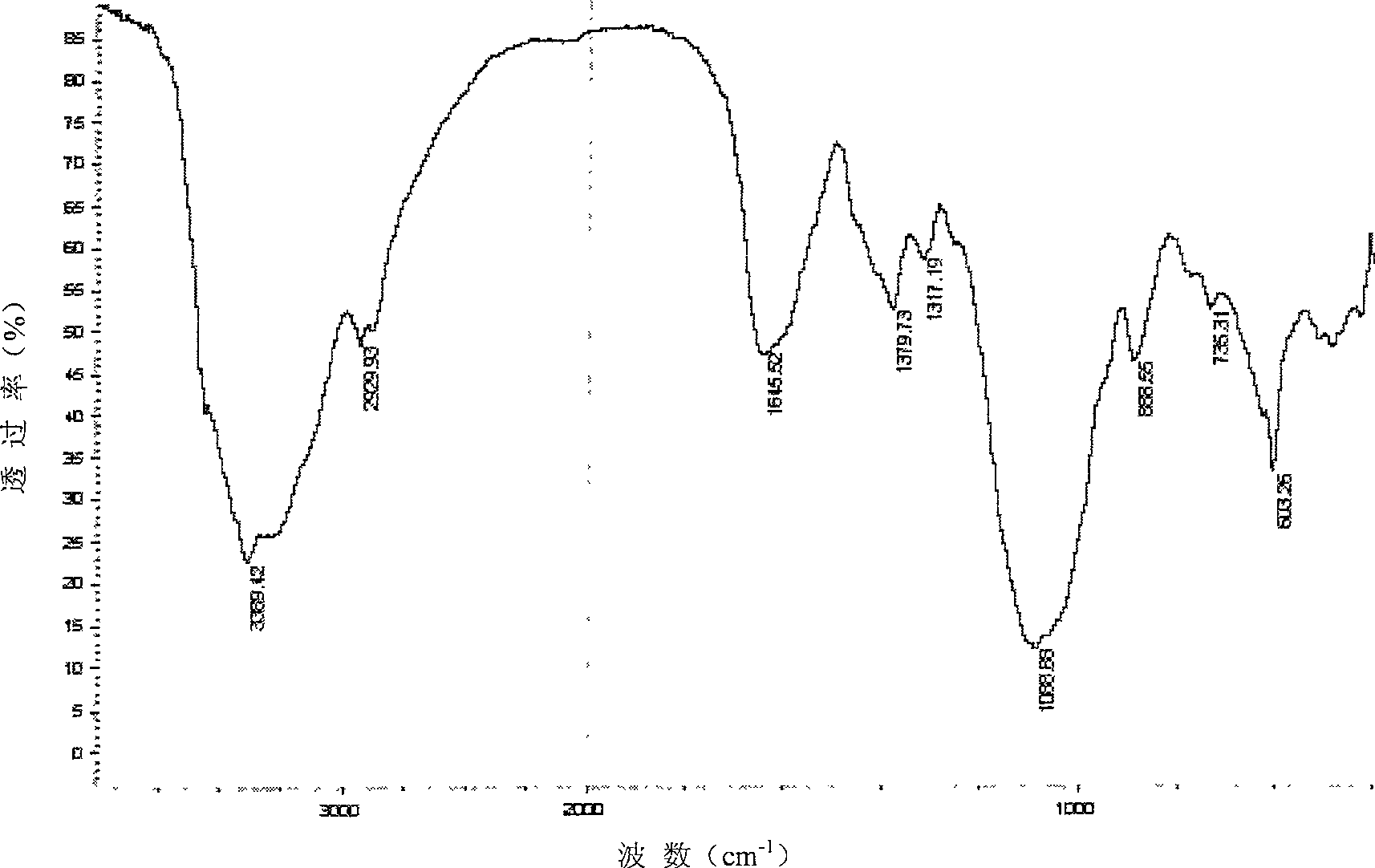

[0034] 10g chitosan (Mw=7.6×10 5 , degree of deacetylation is 84.1%), be dissolved in 150mL1% hydrochloric acid solution, after stirring to form a homogeneous colloid, add H with chitosan equimolar amount 2 o 2 , cover the lid, place the reactor in a microwave oven, and react under 850W microwave power for 3 minutes (intermittent operation, every 1-2 minutes, start the microwave for 1 minute), to obtain a light yellow transparent solution, take it out and quickly cool it to room temperature, and then under magnetic stirring (Magnetic stirring adopts 78-1 type magnetic stirrer) in the reaction solution, directly add CuSO in an equimolar amount with chitosan 4 Aqueous solution, stirred for 4 hours at pH 6, added 3-4 times the amount of acetone to form a precipitate, filtered, washed with 70-80% ethanol several times, no white precipitate was detected by barium chloride solution; finally washed with absolute ethanol Twice, dry to constant weight, and pulverize with a pulverizer...

Embodiment 2

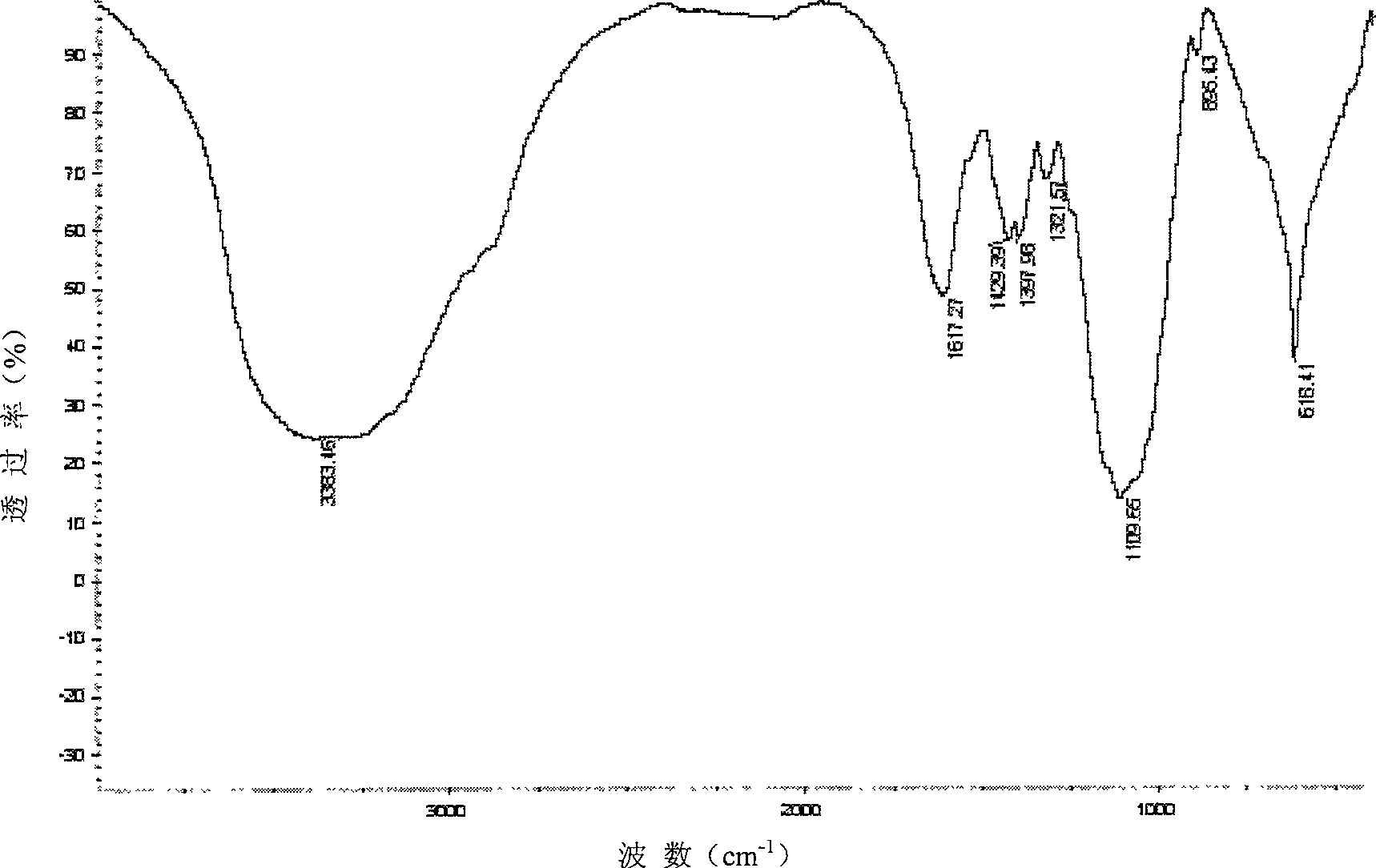

[0038] 10g chitosan (Mw=7.6×10 5 , degree of deacetylation is 84.1%), be dissolved in 150mL1% hydrochloric acid solution, after stirring to form a homogeneous colloid, add H with chitosan equimolar amount 2 o 2 , cover the lid, place the reactor in a microwave oven, and react under 850W microwave power for 3 minutes (intermittent operation, every 1-2 minutes, start the microwave for 1 minute), to obtain a light yellow transparent solution, take it out and quickly cool it to room temperature, and then under magnetic stirring (Magnetic stirring adopts 78-1 type magnetic stirrer) in the reaction solution, directly drop ZnSO with chitosan equimolar amount 4 Aqueous solution, stirred for 4 hours at pH 6, added 3-4 times the amount of acetone to form a precipitate, filtered, washed with 70-80% ethanol several times, no white precipitate was detected by barium chloride solution; finally washed with absolute ethanol Twice, dry to constant weight, and pulverize with a pulverizer to o...

Embodiment 3

[0042] 10g chitosan (Mw=7.6×10 5 , deacetylation degree is 84.1%), be dissolved in 200mL1% hydrochloric acid solution, after stirring to form uniform colloid, add the H that is 0.5 with chitosan molar ratio 2 o 2, cover the lid, place the reactor in a microwave oven, and react under 340W microwave power for 10 minutes (intermittent operation, every 1-2 minutes, start the microwave for 1 minute), to obtain a yellow-brown transparent solution, take it out and quickly cool it to room temperature, and then under magnetic stirring (Magnetic stirring adopts 78-1 type magnetic stirrer) in the reaction solution, directly add CuSO in an equimolar amount with chitosan 4 Aqueous solution, stirred at pH 4 for 12 hours, added 3-4 times the amount of acetone / ethanol mixture (1:1) to form a precipitate, filtered, washed several times with 70-80% ethanol, no white was detected by barium chloride solution Precipitation is formed; finally, it is washed twice with absolute ethanol, dried to co...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com