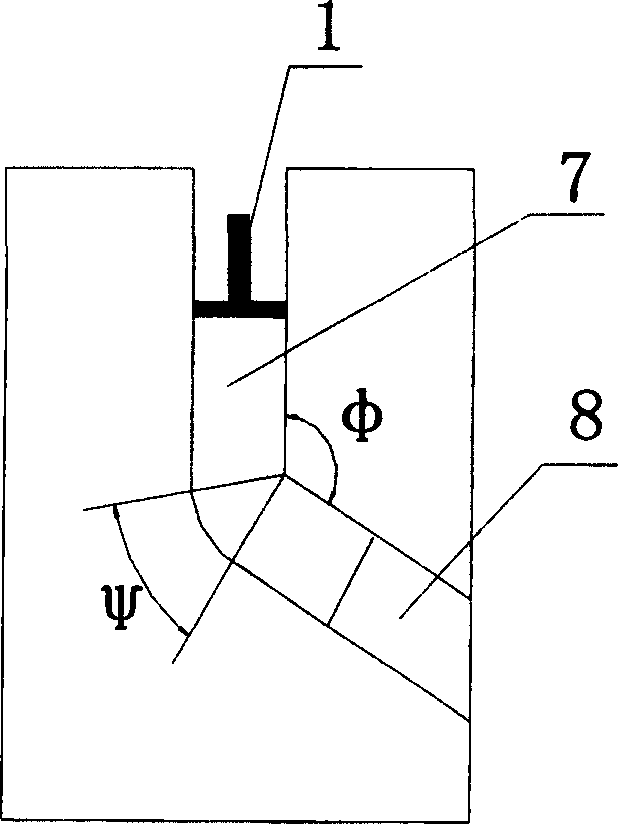

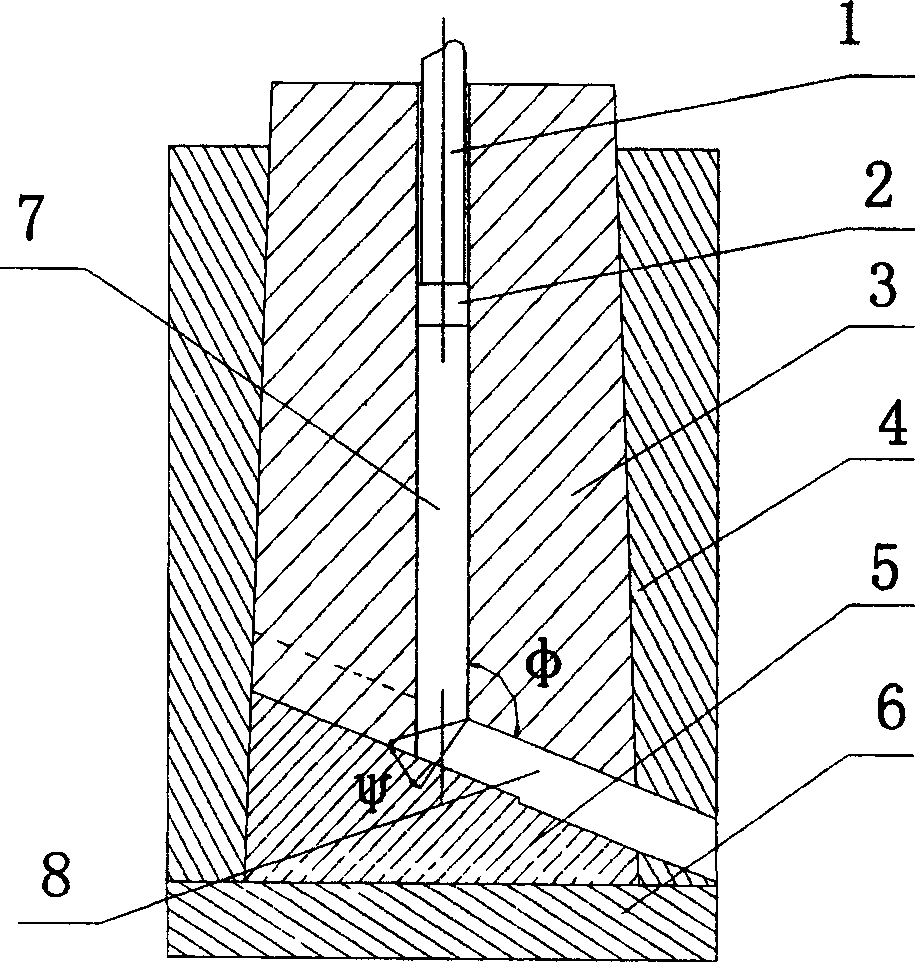

Equal channel deformation mould for preparing block body ultrafine grain metal

A technology of equal channel deformation and ultra-fine grain, which is applied in the direction of metal extrusion dies, etc., to ensure the outlet size, improve the load bearing capacity, and improve the safety.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

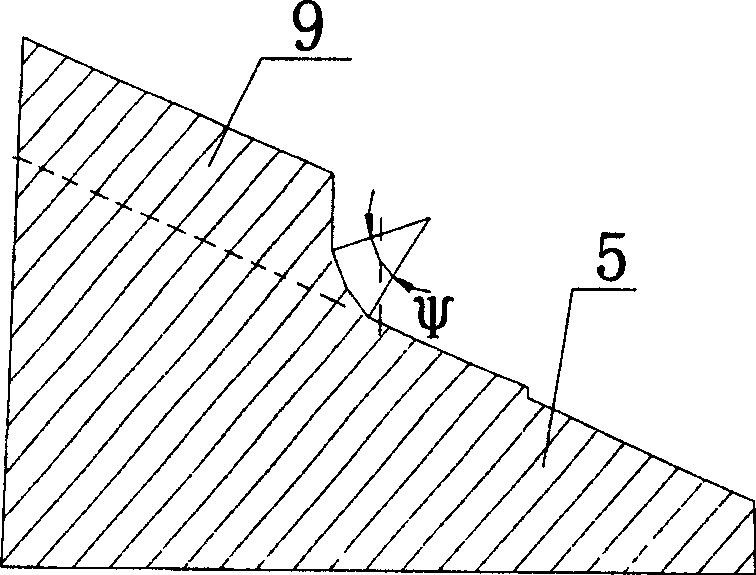

Method used

Image

Examples

Embodiment 1

[0027] Embodiment 1: The deformation material is 99.999% high-purity aluminum, a square material of 12mm×12mm×80mm, which is annealed in a vacuum furnace at 400° C. and kept for 2 hours. The inner angle of the mold is 110°, and the outer angle of the mold is 0°. Deformation at room temperature, the pressing speed is about 0.15mm / s, Figure 4 It is a transmission electron microscope photo after 12 passes of deformation.

Embodiment 2

[0028] Embodiment 2: The deformation material is oxygen-free copper (99.98%), a square material of 12mm * 12mm * 80mm, annealed in a vacuum furnace at 600 ° C, kept for 1 hour, the inner angle of the mold is 90 °, and the outer angle of the mold is 22 °. Deformation at room temperature, the pressing speed is about 1.0mm / s. Figure 5 It is a transmission electron microscope photo after 12 passes of deformation.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com