Method for improving energy supply to a scrap metal pile

A technology of energy supply and waste block, applied in the direction of improvement of process efficiency, lighting and heating equipment, furnace type, etc., can solve problems such as energy impact of metal molten pool, achieve the effect of reducing waste gas problem and eliminating cold zone

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

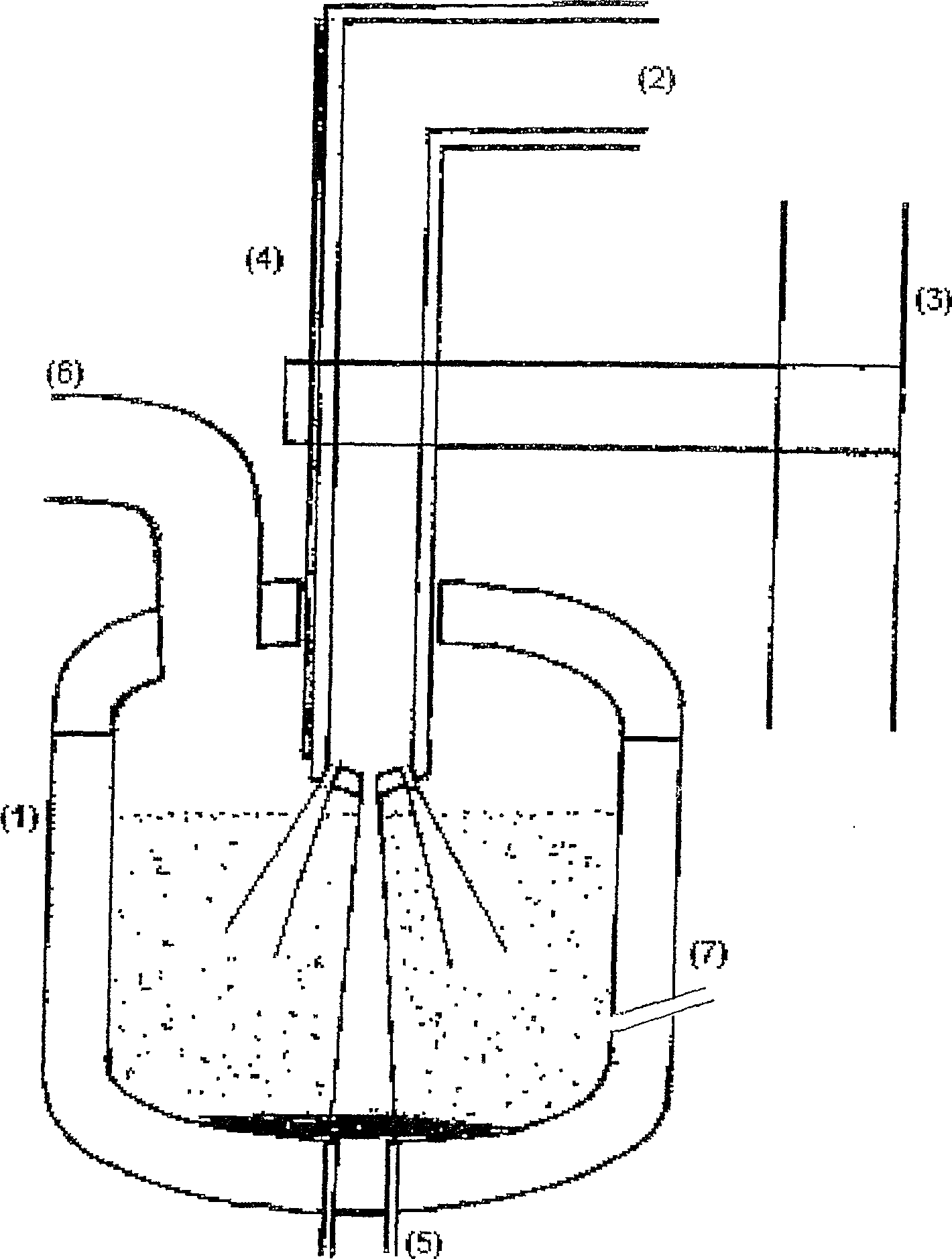

[0033] The following two examples will explain the method of the present invention in detail. In Example 1, approximately 110 tons of scrap were loaded into a 100-ton furnace. Oxygen enriched 40% 1200°C, 0.9 bar 40000Nm by a hot air lance with means for moving up and down 3 / h hot air. The spray gun consists of five nozzles, a central nozzle and four peripheral nozzles, which are inclined at 15° to the vertical direction of the jet. The diameter of the central spout is 20 cm and the diameter of the peripheral spout is 10 cm. Each spout is fitted with a pipe for injecting natural gas. Natural gas blowing rate is 5000Nm in total 3 / h. Simultaneously 2000Nm 3 / h Oxygen is injected through six bottom tuyeres with a diameter of 12mm.

[0034] In example two the bottom tuyeres are not used at all. Oxygen is supplied through a fixed injection system in the side wall of the furnace, the so-called "coherent jet". This example is based on four injection units evenly distributed...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com