Solenoid fuel jet valve

A fuel injection valve, electromagnetic technology, applied in the direction of fuel injection devices, charging systems, machines/engines, etc., can solve the problems of reduced commerciality, reduced connectivity between power supply couplers and power receiver couplers, etc., to achieve Effect of improving connectivity and merchandiseability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

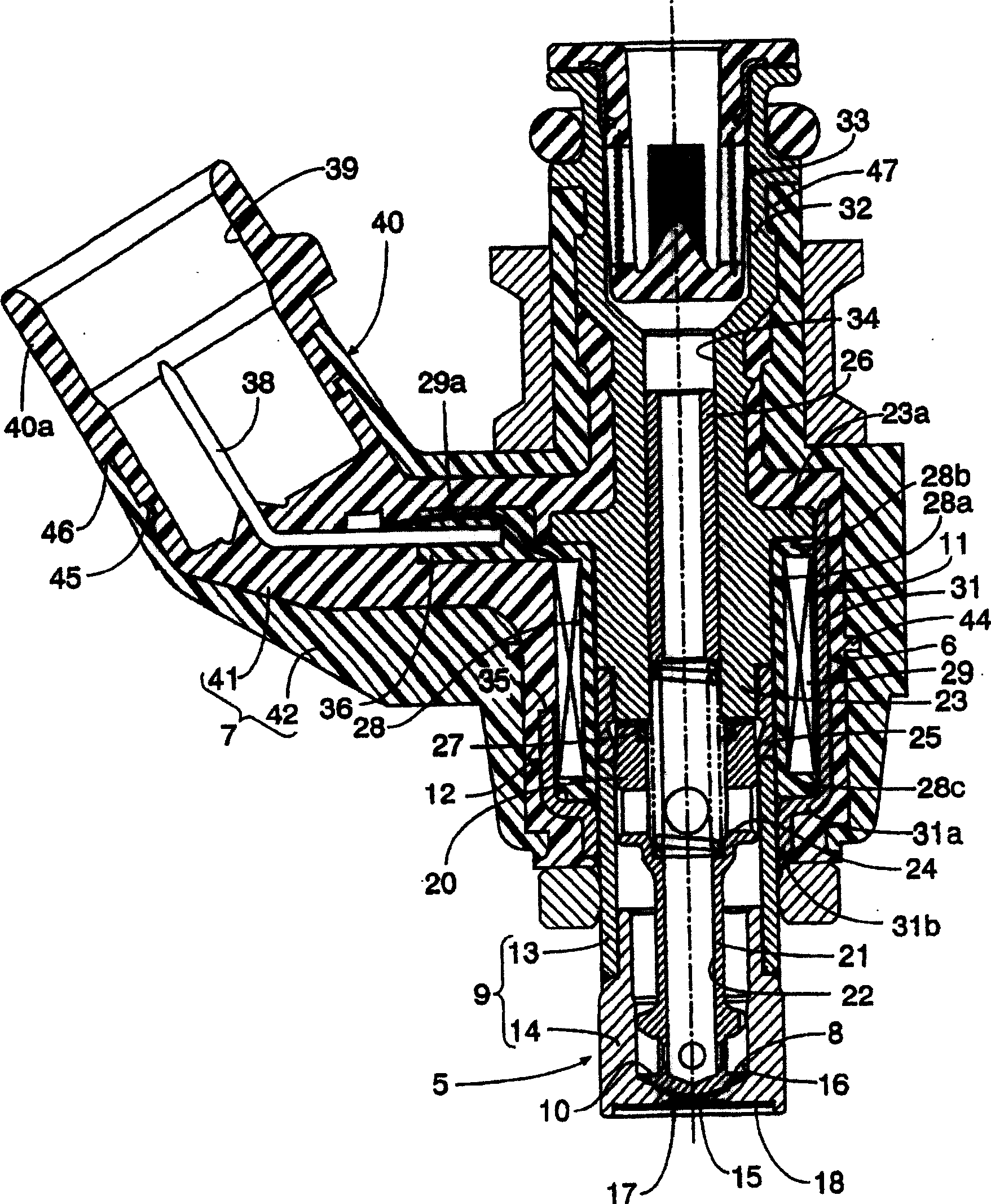

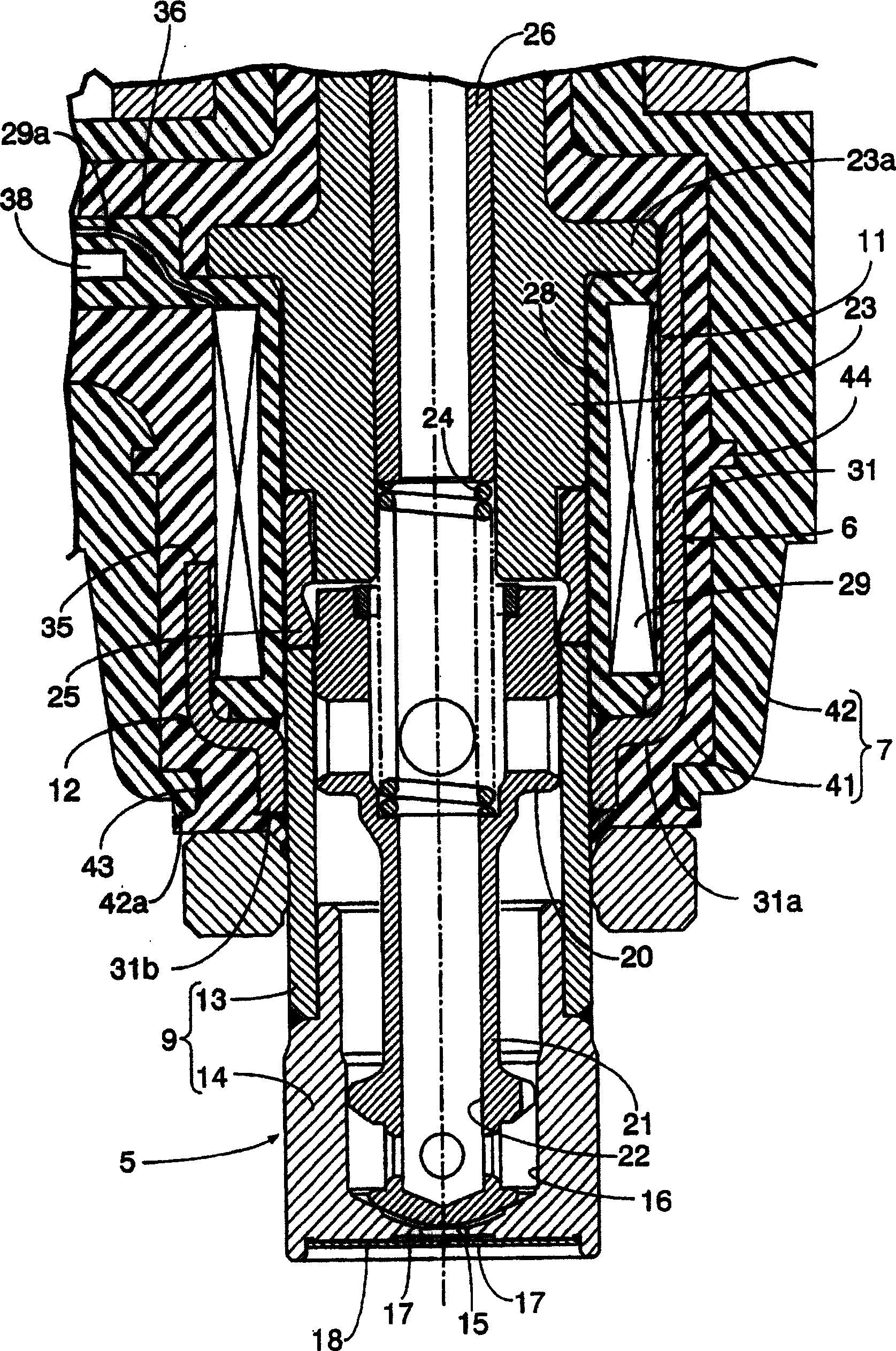

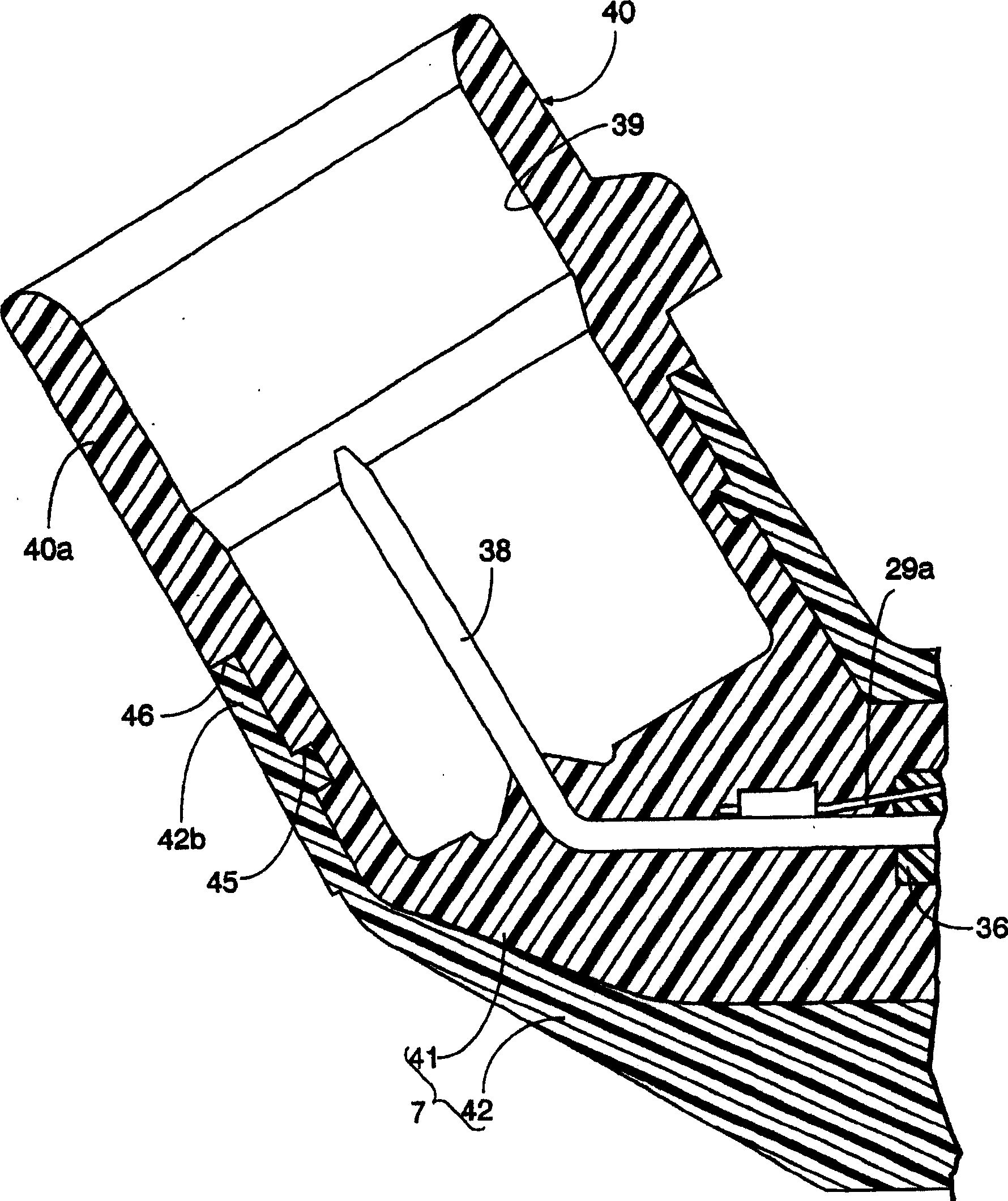

[0042] refer to Figure 1 ~ Figure 4 To describe the first embodiment of the present invention, first, in figure 1 Among them, an electromagnetic fuel injection valve for injecting fuel to an unillustrated engine has a valve operating part 5 that accommodates a valve body 10 in a valve casing 9 having a valve seat 8 at the front end, and the valve body 10 is seated on the The direction of the valve seat 8 is elastically biased; the solenoid part 6, wherein the coil assembly 11 that can generate the electromagnetic force that drives the valve body 10 to the side away from the valve seat 8, is housed in In the solenoid case 12 provided continuously with the valve case 9; the resin molded part 7 made of synthetic resin has a power receiving coupler 40 integrally, and covers at least the solenoid part 6, and the receiving The power coupler 40 faces the power receiving side connection terminal 38 connected to the coil 29 of the coil assembly 11 .

[0043] Also refer to figure 2...

Embodiment 2

[0068] Figure 5 Showing the second embodiment of the present invention, the engagement portion provided on the outer periphery of the first resin molded layer 41 along the axial direction of the valve case 5 at the portion corresponding to the coil assembly 11 may be an annular engagement recess 48, By restricting the displacement of the second resin molded layer 42 to the rear side by such engaging recessed portion 48, the same effect as that of the above-described first embodiment can be exhibited.

Embodiment 3

[0070] Image 6 Showing the third embodiment of the present invention, the engagement portion provided on the outer periphery of the first resin molded layer 41 along the axial direction of the valve case 5 at the portion corresponding to the coil assembly 11 may be an annular engagement facing forward. Even in the step portion 49 , by restricting the rearward displacement of the second resin molded layer 42 by the engaging step portion 49 , the same effects as those of the first and second embodiments described above can be exhibited.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com