High-speed carriage-axle gearbox

A shaft gearbox, high-speed technology, applied in the direction of gear transmission, belt/chain/gear, mechanical equipment, etc., can solve the problem of difficult manufacture, use and maintenance, can not meet the requirements of high-speed running and linked operation, thin-walled meshing sleeve Difficulty in manufacturing and other issues

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] The present invention will be described in further detail below with reference to the embodiments given in the accompanying drawings.

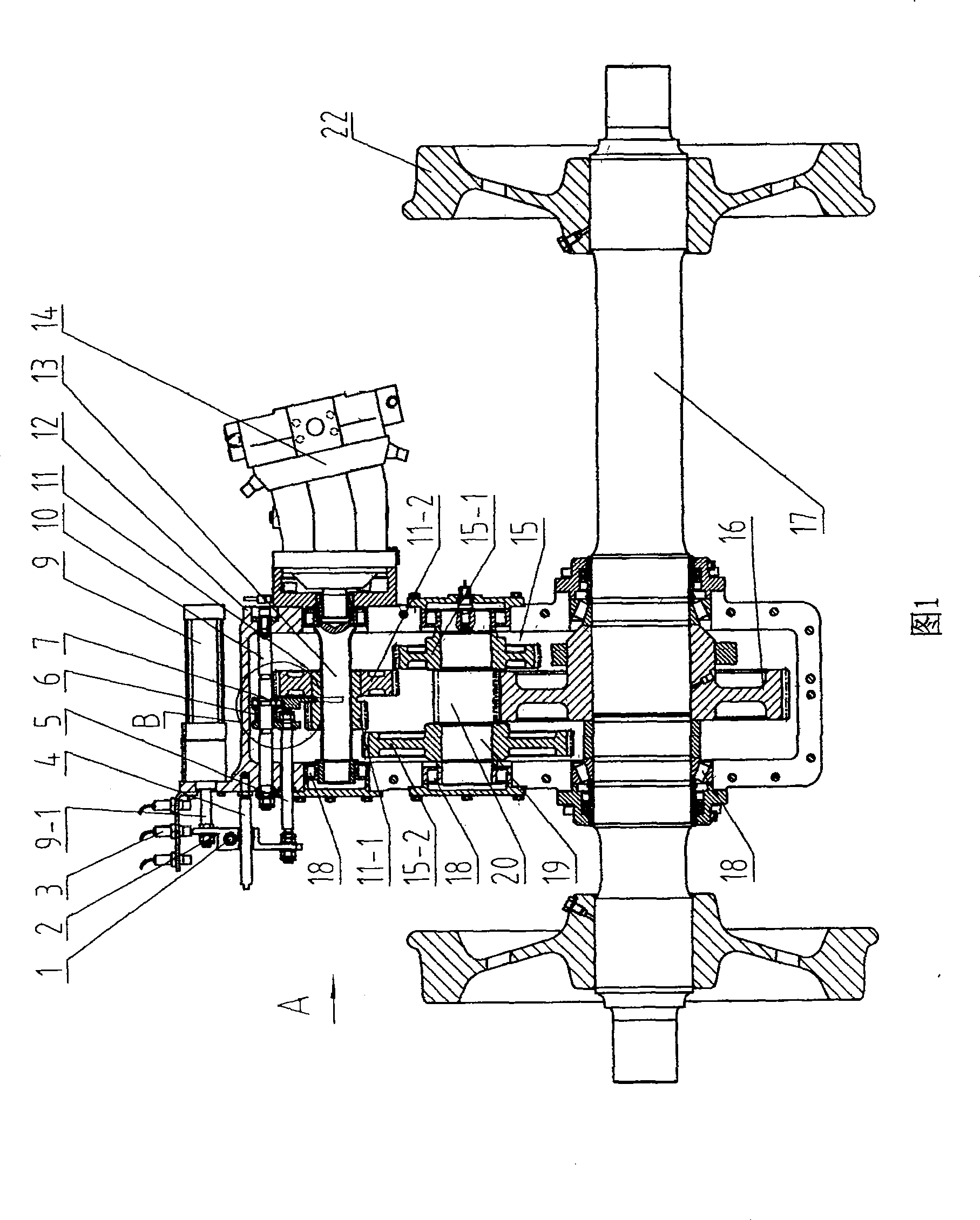

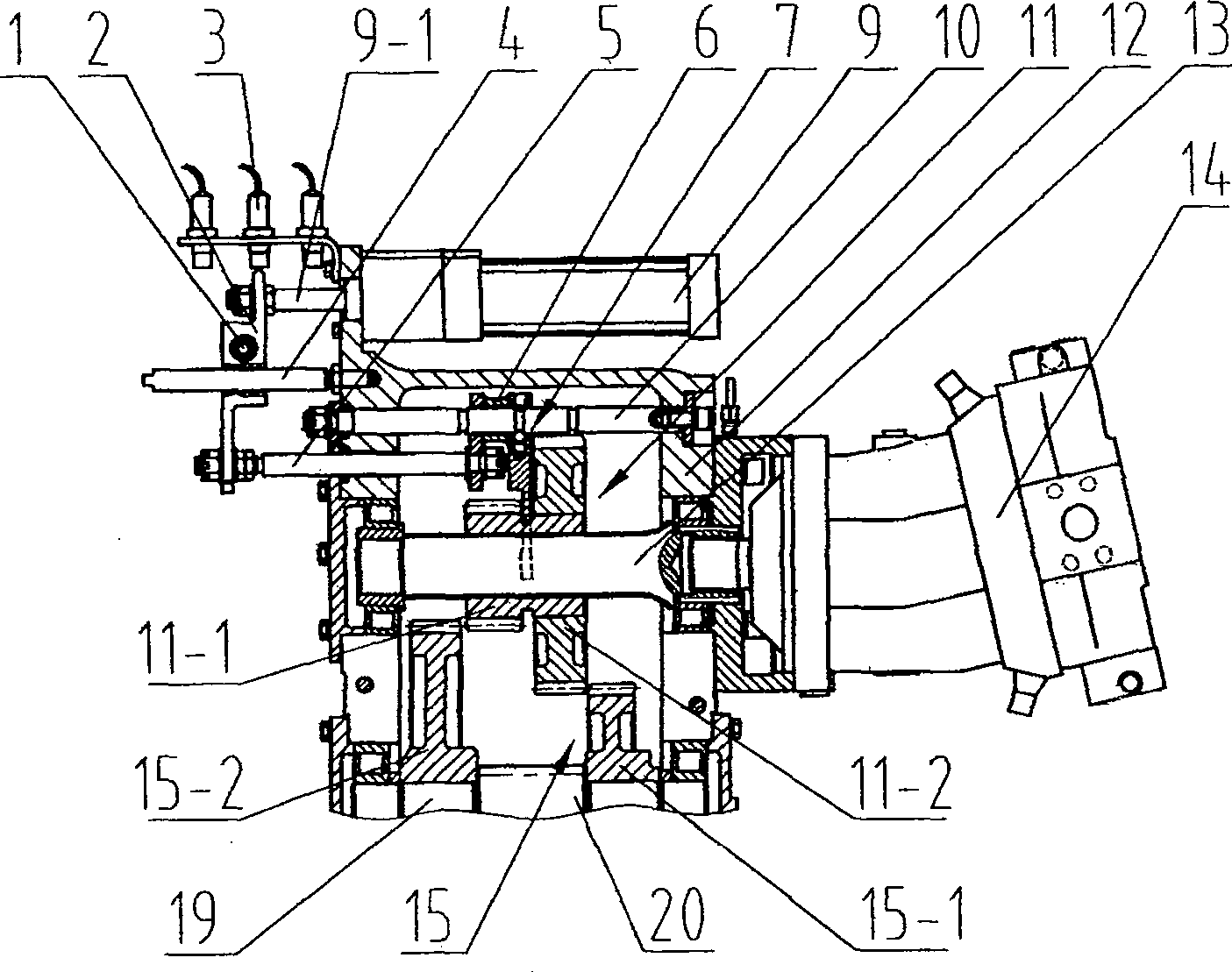

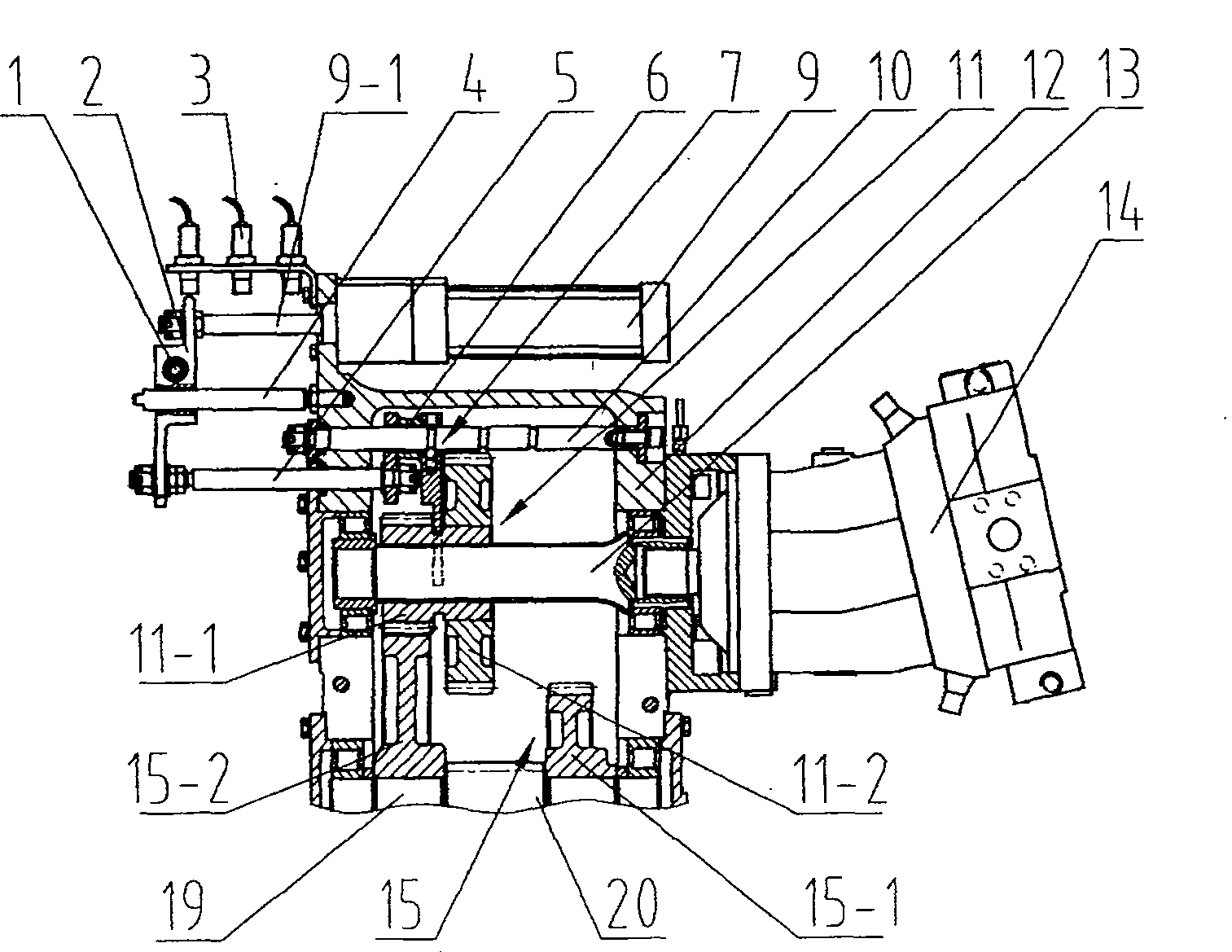

[0021] As shown in Figures 1, 2, 3, 4, 5, and 7, the high-speed axle gear box of the present invention includes a box body 12, a shifting mechanism, a spline shaft 13, a driving gear 11, an intermediate gear 15, and an intermediate shaft. 19. The intermediate shaft driving gear 20, the driven gear 16, the bearing 18, the lubrication system 21 and the axle 17, the driving gear 11 meshes with the spline shaft 13 through the internal spline, the driving gear 11 can be meshed with the intermediate gear 15 or disengaged, the intermediate The shaft driving gear 20 meshes with the driven gear 16, the driven gear 16 is fixed on the axle 17, the driving gear 11 is a double gear, including a first gear 11-1 and a second gear 11-2, and the intermediate gear 15 includes a high-speed gear 15-1 and low-speed gear 15-2, the shift fork 6 in the shift t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com