Method for detecting reinforcing bar cage length in concrete pouring pile by magnetic logging method

A technology of cast-in-place piles and steel cages, which is applied in the direction of electric/magnetic detection for logging records, can solve problems such as not popularization and application, and can not solve the problems of length detection of steel cages, and achieves low detection cost. , The method is intuitive and simple, and the effect of promotion is simple

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

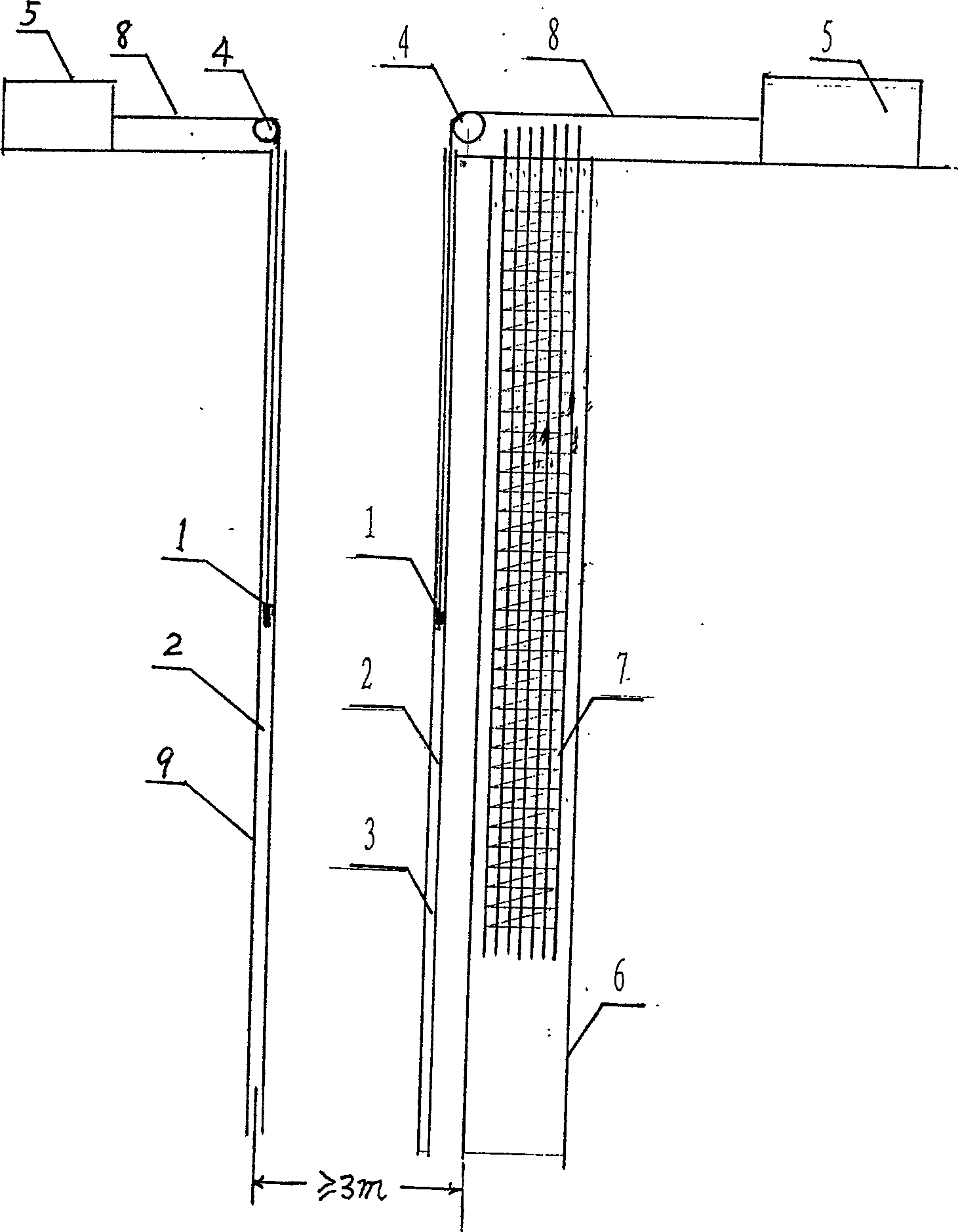

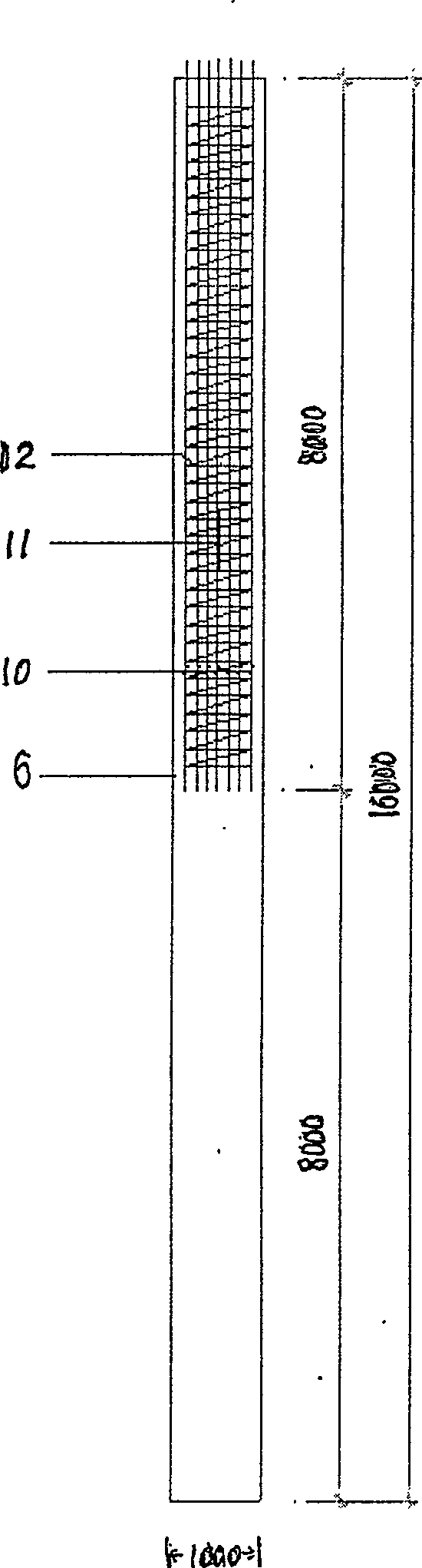

[0028] Figure 2—A It is the No. 1 cast-in-situ pile with a diameter of 1m and a length of 16m (the unit in the figure is mm), and the situation of the No. 1 cast-in-place pile is shown in Table 1.

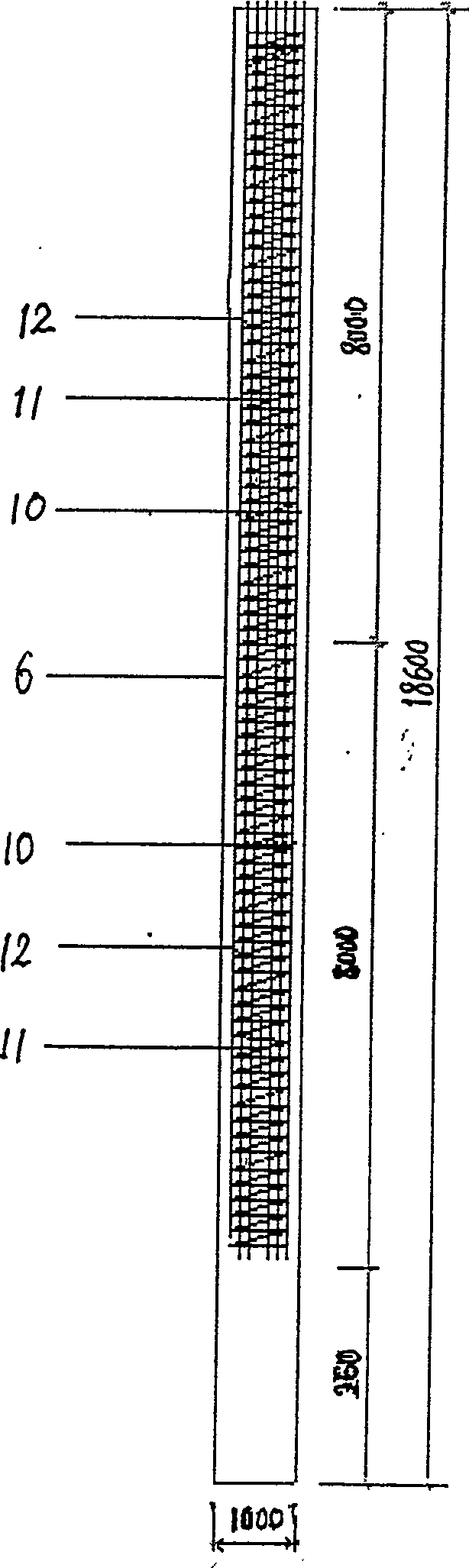

[0029] Figure 2-B It is the No. 2 cast-in-situ pile with a diameter of 1m and a length of 18.6m (the unit is mm in the figure). The situation of the No. 2 cast-in-place pile is shown in Table 2.

[0030] Table 1 Situation of cast-in-place pile No. 1

[0031]

parts

pile length

The length of the reinforcement cage in the pile

(m) Reinforcement cages in piles

Upper section

8

8

The main reinforcement (10) is 24 pieces of HRB335 steel with a diameter of Φ16

ribs; ribs (12) are Φ16 in diameter and 2m apart

HRB335 steel bar; Spiral bar (11) is diameter Φ8, between

HPB235 steel bars at a distance of 0.2m lower paragraph 8 0 no steel cage, made of concrete

[0032] Table 2 Sit...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com