Switch device of parallel connection vacuum arc extinguishing chamber

A vacuum interrupter and switchgear technology, which is applied to electric switches, high-voltage/high-current switches, high-voltage air circuit breakers, etc., can solve the problems of complex structure, cost increase, space limitation, etc. High contact reliability ensures normal operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

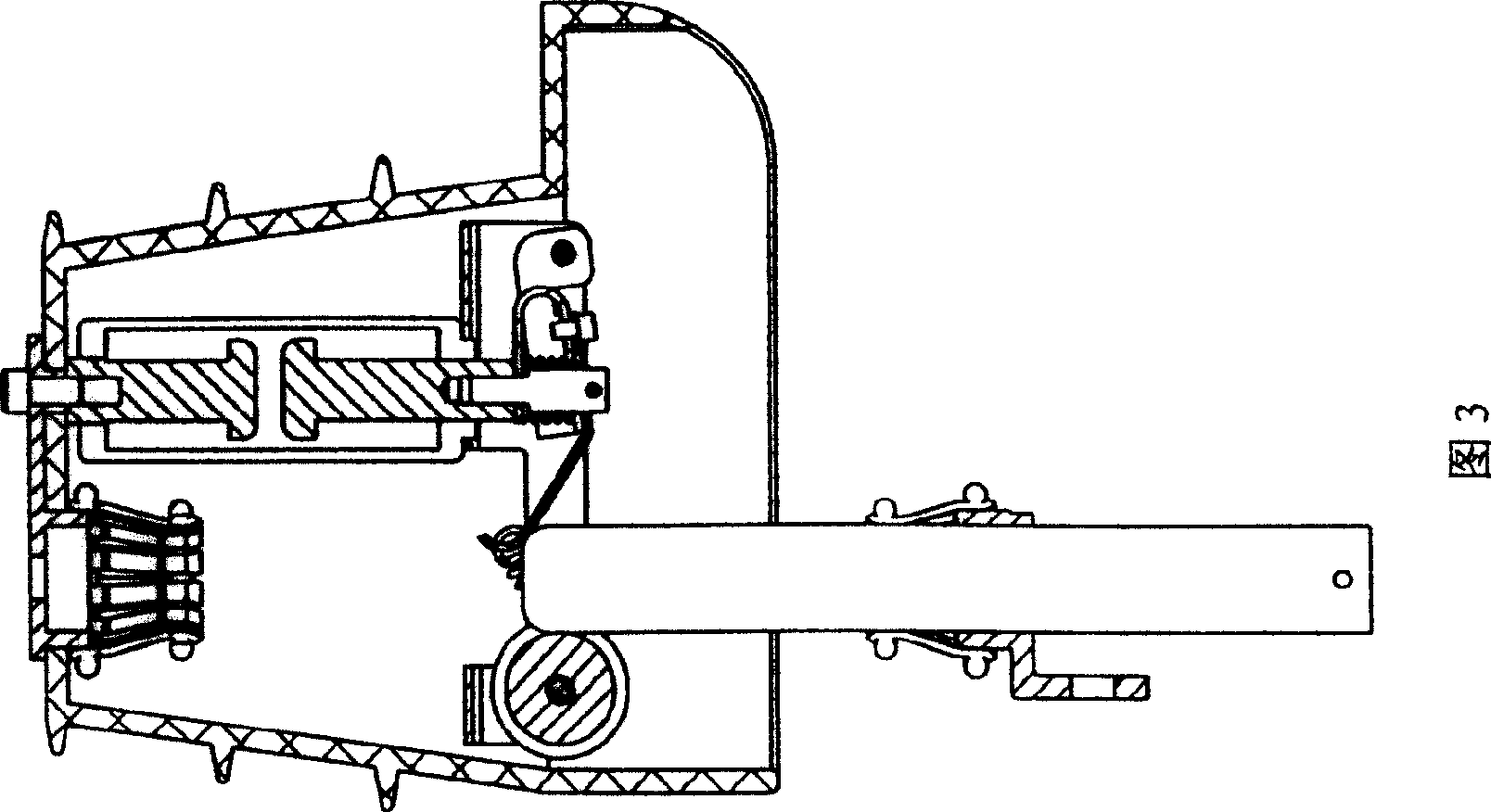

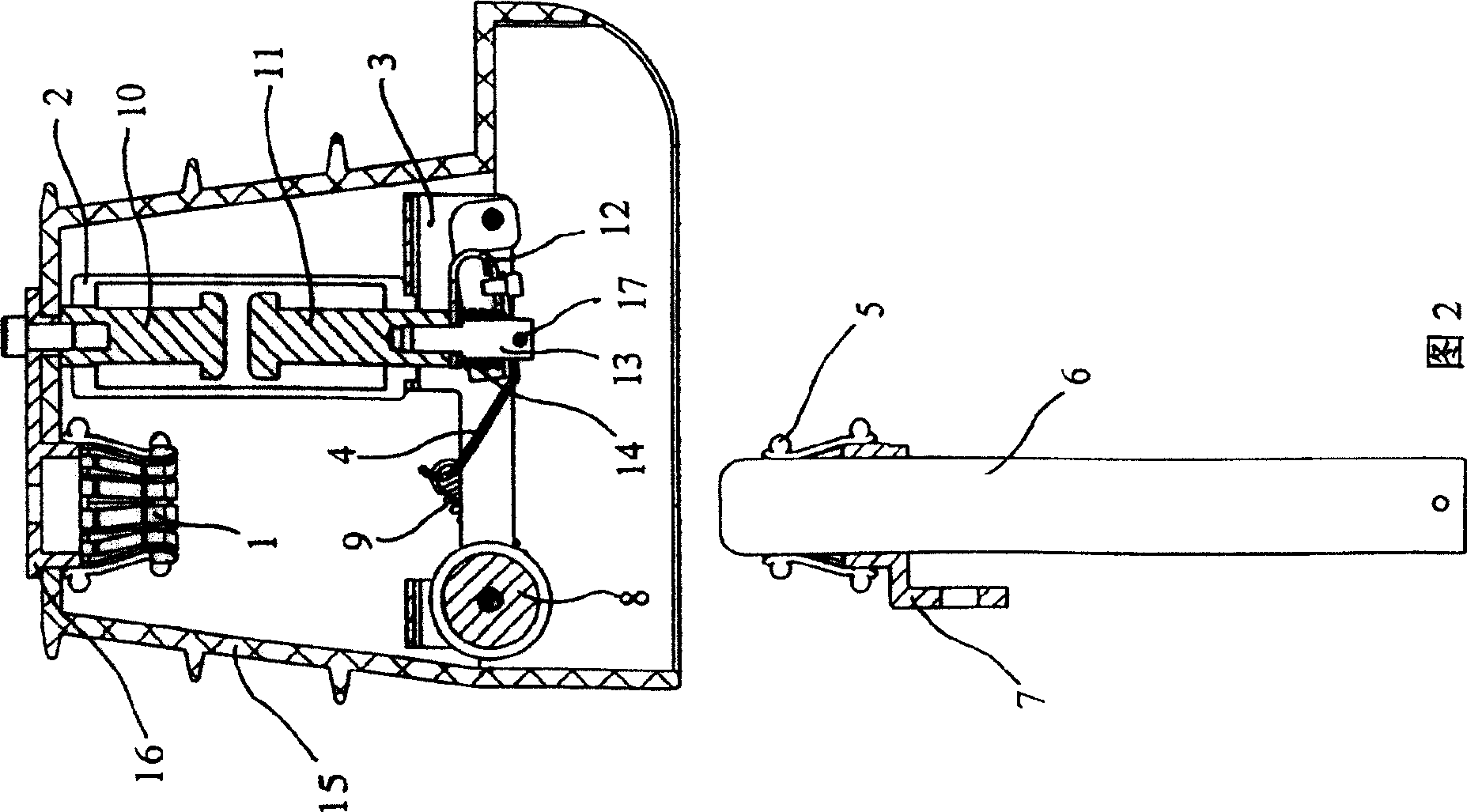

[0018] The embodiments of the present invention will be described in further detail below in conjunction with the accompanying drawings.

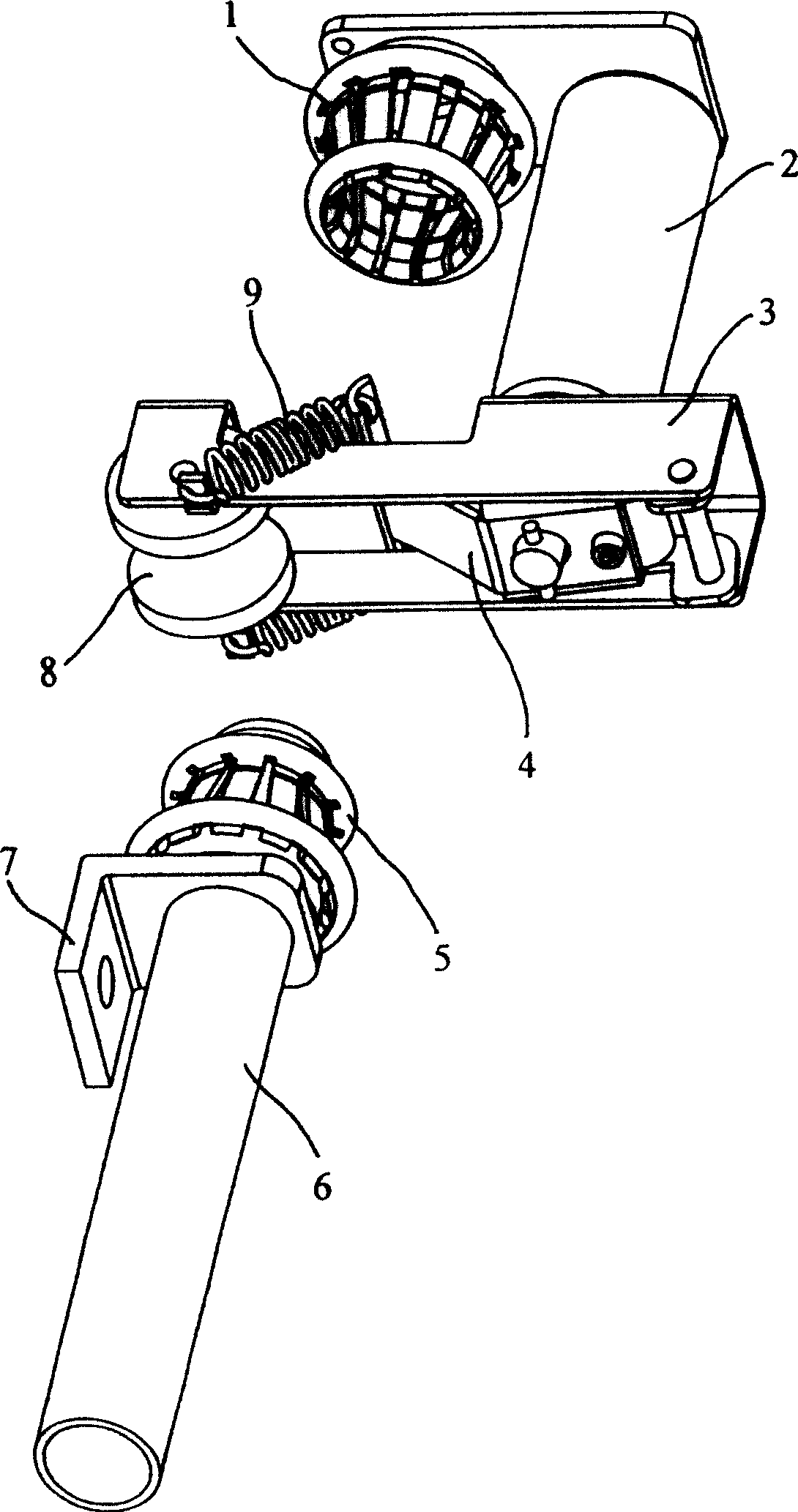

[0019] Such as figure 1 As shown in ~2, the switchgear of the parallel vacuum interrupter includes an insulating cover 15 and a bracket 3 fixed on the insulating cover, and a main circuit and an auxiliary circuit are installed in parallel in the insulating cover.

[0020] The upper conductive seat 16 at the static end of the main circuit is fixed on the top of the insulating cover together with the plum blossom-shaped static main contact 1, and the circular tube-shaped moving main contact 6 at the moving end is interspersed with the mutually fixed plum blossom-shaped transition contact seat 5 and the lower conductive In the seat 7, the lower conductive seat is a conductor fixed on the insulator of the load switch. The moving main contact is driven by the insulating arm (not shown in the figure) to move up and down in a straight line track, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com