Water screen accelerated cooling system for medium and heavy plate after on line post rolling

An accelerated cooling system and water curtain technology, applied in cooling beds, metal rolling, metal rolling, etc., can solve the problems of increasing steel plate processing costs, restricting the improvement and improvement of steel plate performance, and increasing equipment costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

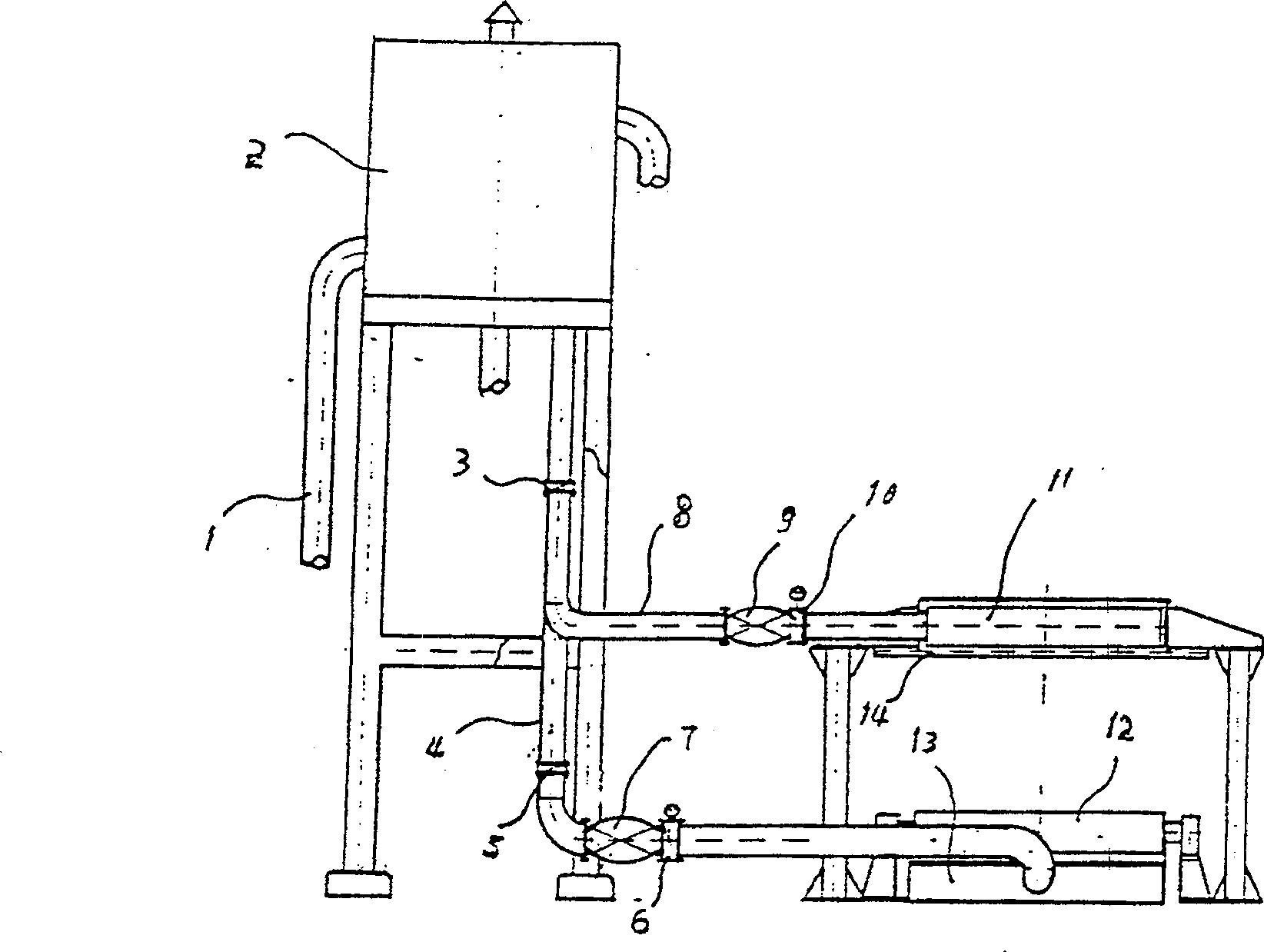

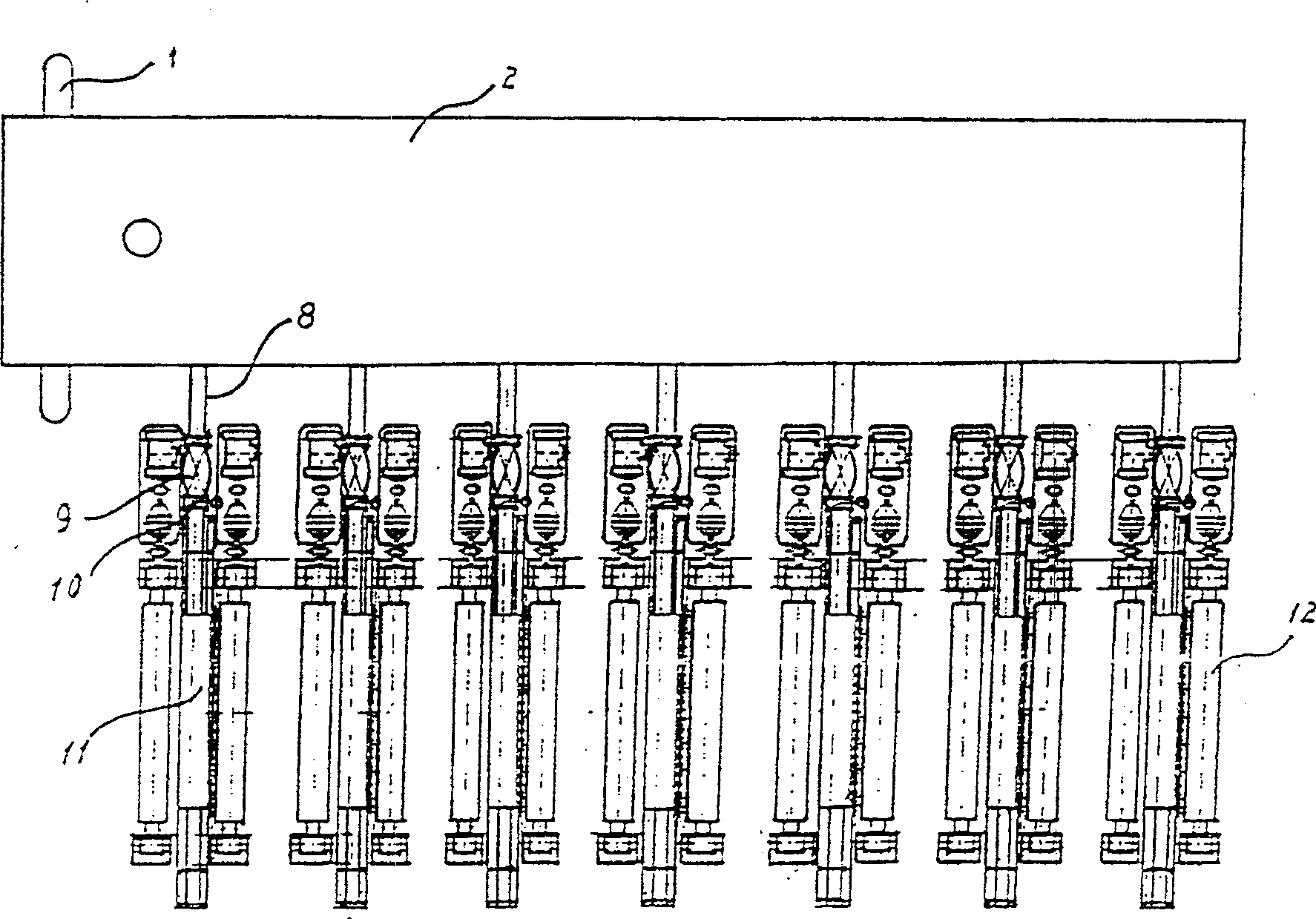

[0009] In order to clearly illustrate the technical features of the solution, the solution will be described below through a specific implementation.

[0010] It can be seen from the accompanying drawings that the water curtain accelerated cooling system after the online rolling of medium and heavy plates in this scheme includes a high-level water tank (2) with a water inlet pipe (1) and water supply through the upper water curtain water supply pipe (8) and the lower water curtain. The pipe (4) is connected with the high-level water tank (2), and the upper water curtain device (11) and the lower water curtain device (13) are arranged correspondingly up and down on the roller table (12). In this scheme, an upper water curtain device (11) and a corresponding lower water curtain device (13) form a water curtain group, and there are 3-7 water curtain groups in this system, and this specific embodiment adopts 7 water curtains Group, the distance between each water curtain group sho...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| width | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com