Substrate for ink jet head, ink jet head using the same, and manufacturing method thereof

An inkjet head and substrate technology, applied in printing and other directions, can solve problems such as the inability to stably perform pattern formation of the upper protective layer

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

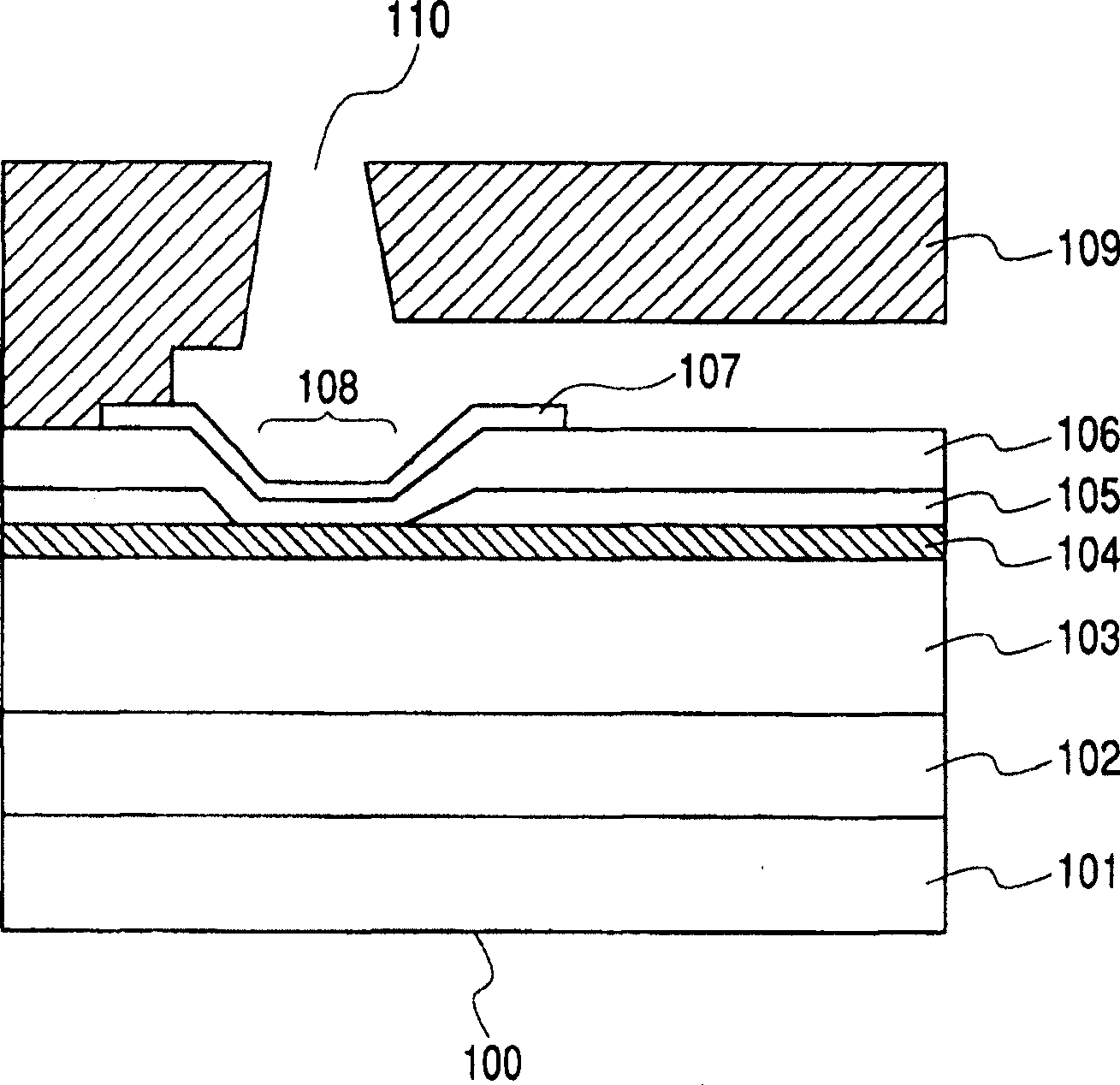

[0025] figure 1 is an illustrative partial sectional view showing a substrate for an ink jet head to which the present invention is applied.

[0026] exist figure 1 , reference numeral 101 denotes a silicon substrate, and reference numeral 102 denotes a heat accumulating layer made of a thermally oxidized film. Reference numeral 103 denotes an interlayer film made of SiO film, SiN film, etc., which also has a function of accumulating heat, reference numeral 104 denotes a thermal resistance layer, and reference numeral 105 denotes an interlayer film made of such as Al, A metal wiring layer made of metallic materials such as Al-Si and Al-Cu is used as a wiring, and reference numeral 106 denotes a protective layer made of SiO film, SiN film, etc., and the protective layer 106 also serves as an insulating layer. Reference numeral 107 denotes an upper protective layer provided on the protective layer 106 for protecting the electrothermal conversion element from chemical and physi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com