Gem tri-dimensional cut detection device based on machine vision and its method

A technology of machine vision and detection method, which is applied in the direction of instruments, measuring devices, testing jewelry, etc., can solve the problems of poor practicability, complicated process, low efficiency, etc., and achieve the effect of convenient use, convenient viewing, and convenient batch detection

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

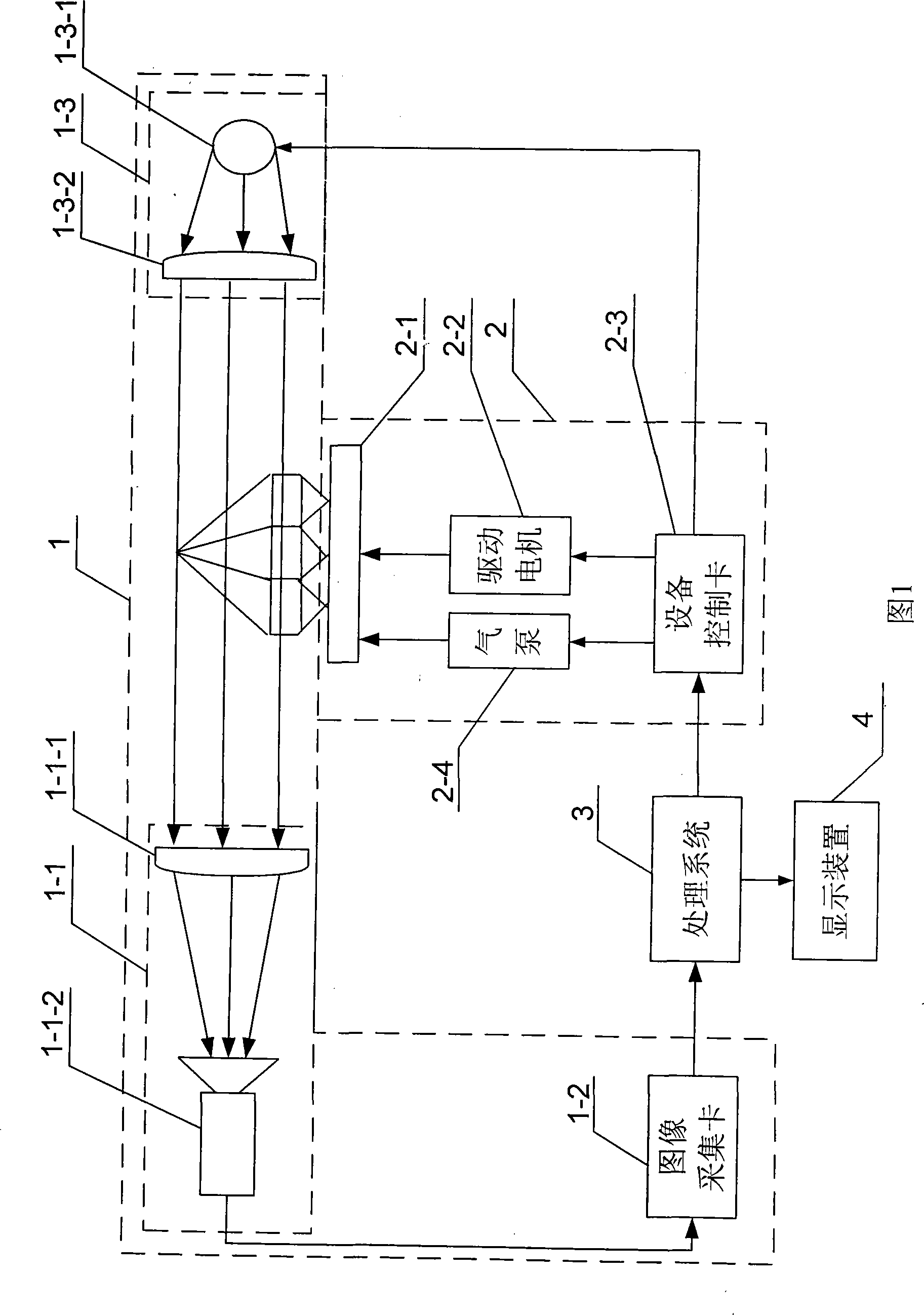

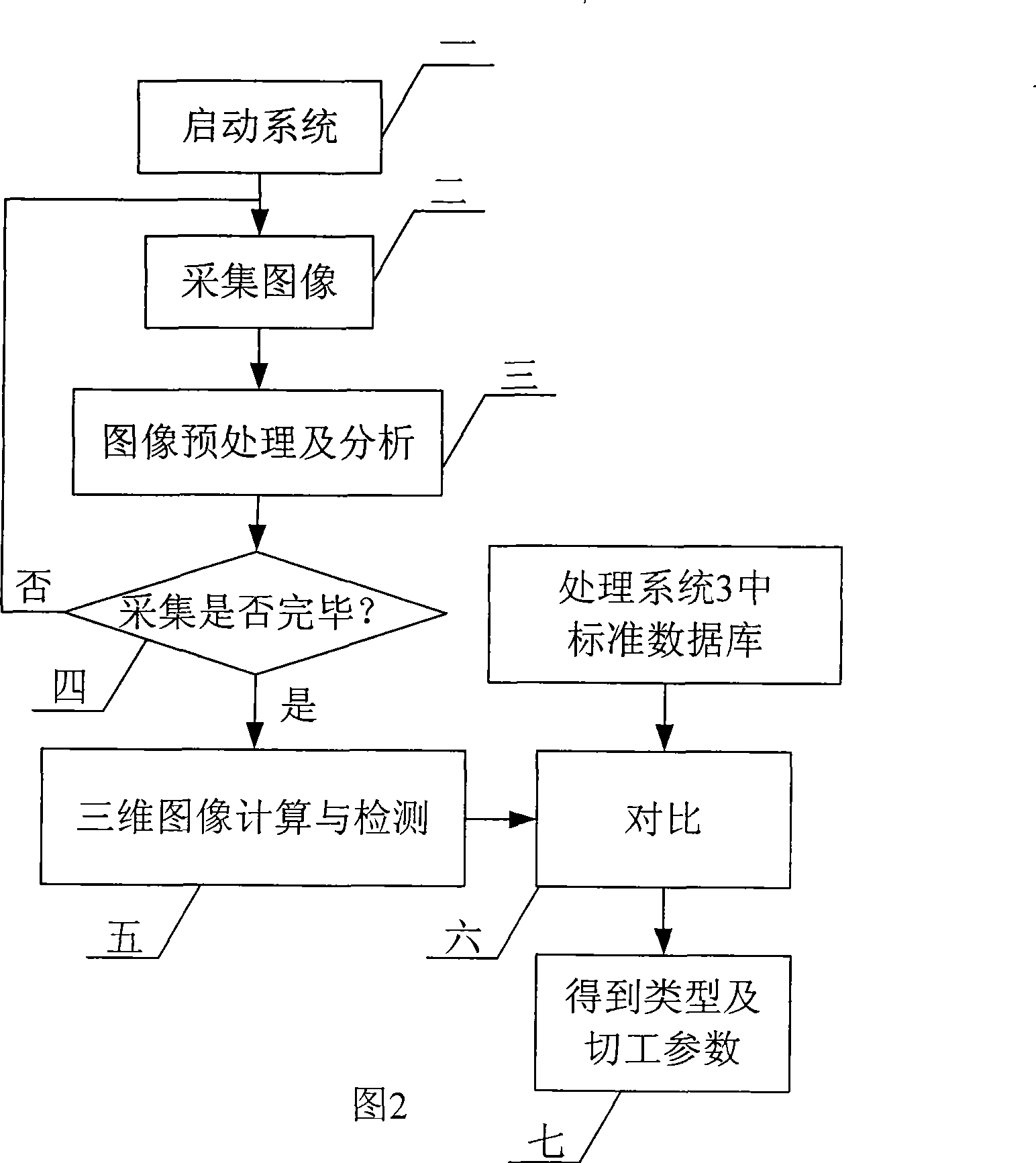

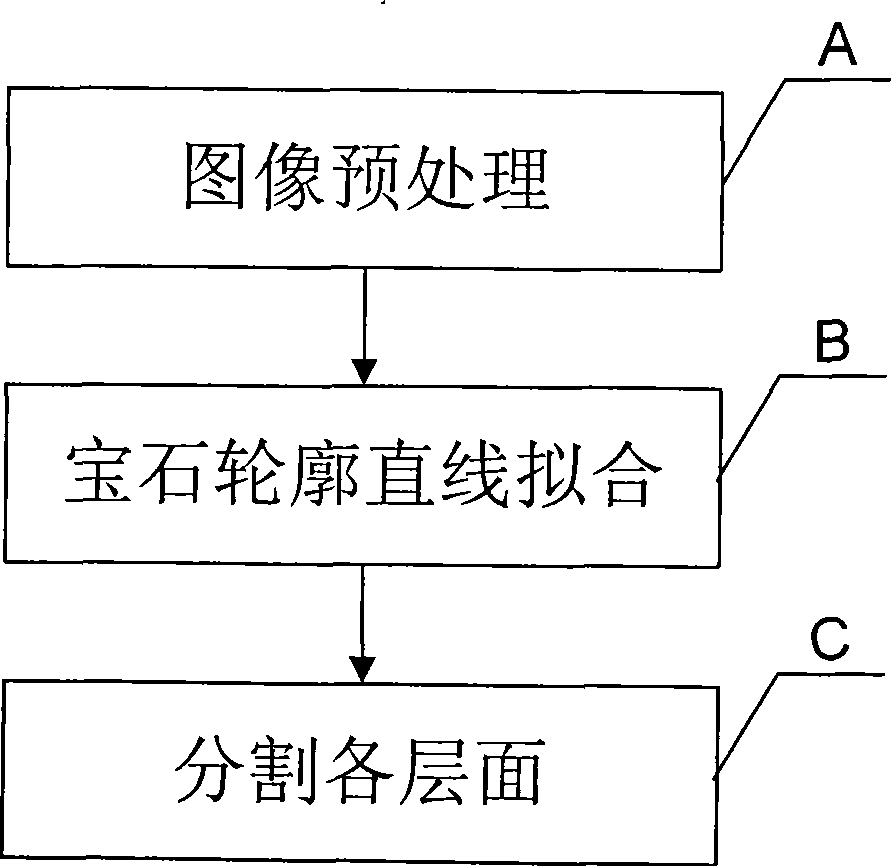

[0020] Specific embodiment one: this embodiment is described in conjunction with Fig. 1, the device of this embodiment is made up of image acquisition system 1, rotating platform equipment 2 and processing system 3, and described image acquisition system 1 is made up of acquisition device 1-1, image acquisition card 1-2 and lighting device 1-3, the signal output end of the acquisition device 1-1 is connected to the signal input end of the image acquisition card 1-2, and the signal output end of the image acquisition card 1-2 is connected to the signal input end of the processing system 3 , the acquisition device 1-1, the gem A to be tested and the lighting device 1-3 are sequentially arranged on the same axis, and the rotating platform device 2 is composed of a platform body 2-1, a drive motor 2-2 and a device control card 2 -3, the signal output end of the processing system 3 is connected to the signal input end of the equipment control card 2-3, the first control end of the e...

specific Embodiment approach 2

[0021] Specific embodiment 2: This embodiment is described in conjunction with FIG. 1. The difference between this embodiment and specific embodiment 1 is that the acquisition device 1-1 is composed of a lens 1-1-1 and a camera 1-1-2. The camera 1-1- The imaging plane of 2 is arranged on the focal plane of lens 1-1-1, and camera 1-1-2 is SONY 1 / 3 " 600 line high-definition camera. Other composition and connection mode are identical with specific embodiment one. Through lens 1 -1-1 gathers the information to the camera 1-1-2 to make the collected image information more accurate.

specific Embodiment approach 3

[0022] Specific Embodiment 3: This embodiment is described in conjunction with FIG. 1. The difference between this embodiment and Embodiment 1 is that the lighting device 1-3 is composed of an auxiliary light source 1-3-1 and a Fresnel lens 1-3-2. The light source 1-3-1 is arranged at the focus of the Fresnel lens 1-3-2. Other compositions and connection methods are the same as those in Embodiment 1. During the image acquisition process, the gem detection backlight provided by the auxiliary light source 1-3-1 is transformed into parallel light through the Fresnel lens 1-3-2.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com