Magnetoresistive sensor and Magnetoresistive head

A magnetoresistance and sensor technology, applied in the fields of magnetic field controlled resistors, manufacturing flux-sensitive magnetic heads, magnetic recording heads, etc., can solve problems such as increasing the reading gap

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

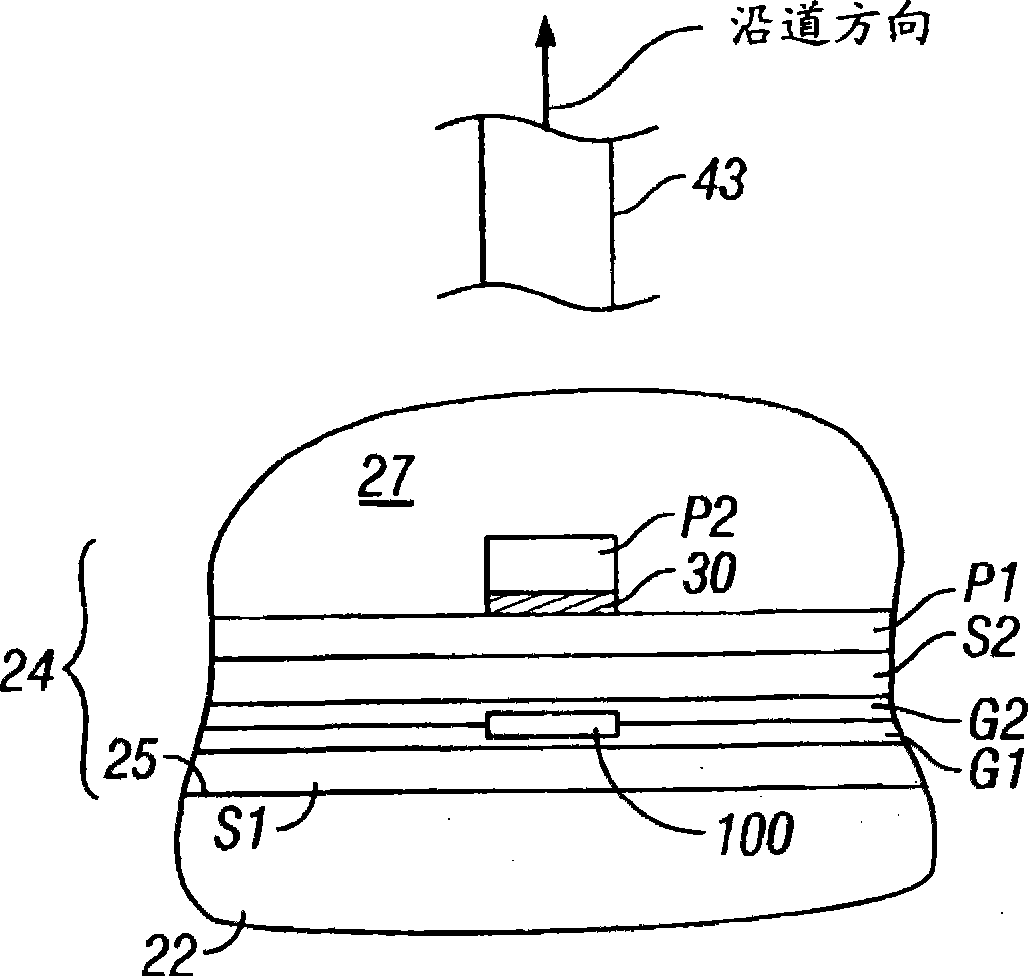

[0016] The sensor of the present invention can be used as a magnetoresistive (MR) read head for a magnetic recording disk drive, so reference will be made to Figure 1-3 Briefly describe the operation of a conventional disk drive. However, the sensor of the present invention is fully applicable as a magnetic field sensor and as a read head for magnetic recording media other than magnetic recording disks.

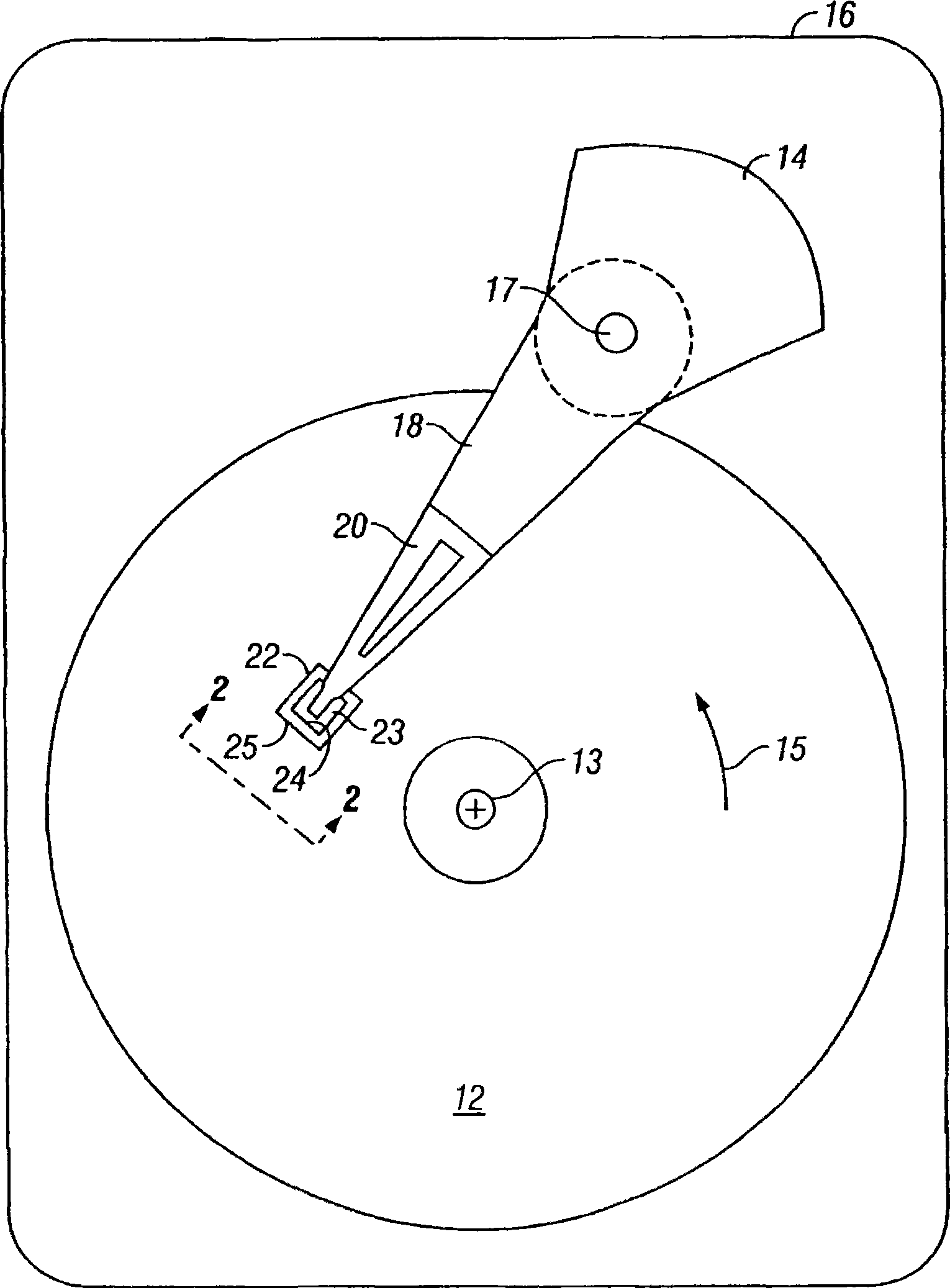

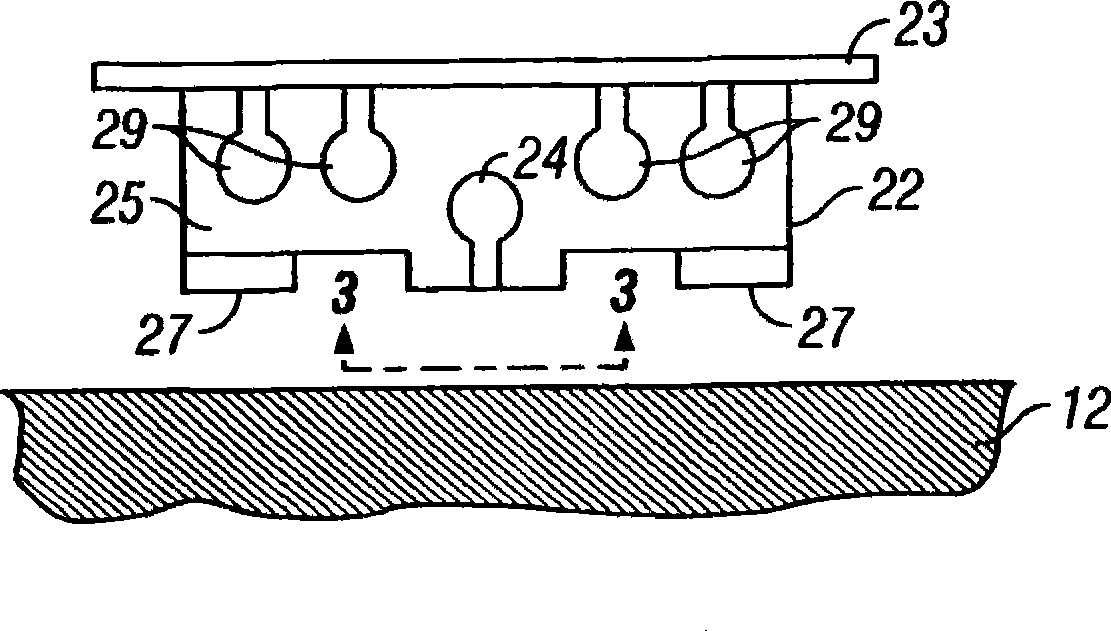

[0017] figure 1 is a block diagram of a conventional magnetic recording hard drive. The disk drive includes a magnetic recording disk 12 and a rotating voice coil motor (VCM) actuator 14 supported on a disk drive housing or base 16 . Disk 12 has a center of rotation 13 and is rotated in direction 15 by a spindle motor (not shown) mounted to base 16 . The actuator 14 rotates about an axis 17 and includes a rigid actuator arm 18 . A generally flexible cantilever 20 includes a flexure element 23 and is connected to the end of the arm 18 . A head mount or air-bearing slider...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com