Wiper blade

A technology of wiper blades and wiper strips, which is applied in vehicle cleaning, vehicle maintenance, transportation and packaging, etc., can solve the problems of expensive manufacturing process and weakening, and achieve the effects of avoiding weakening, effortless assembly and improving stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

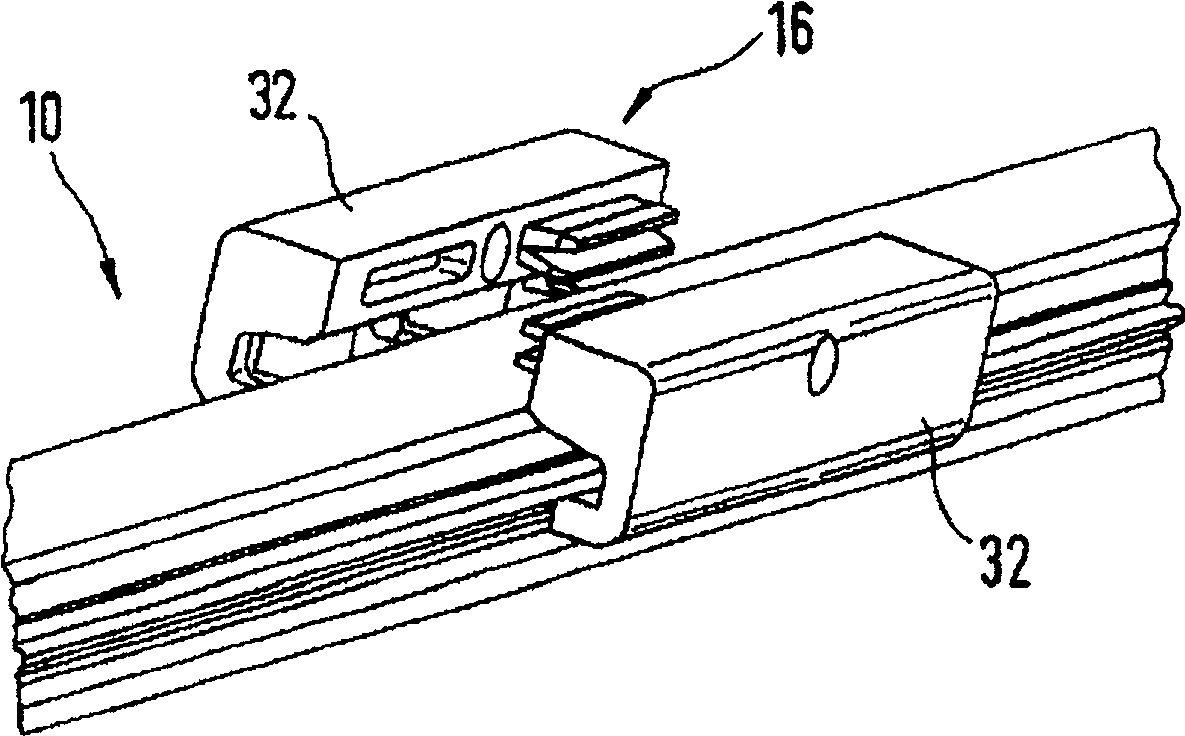

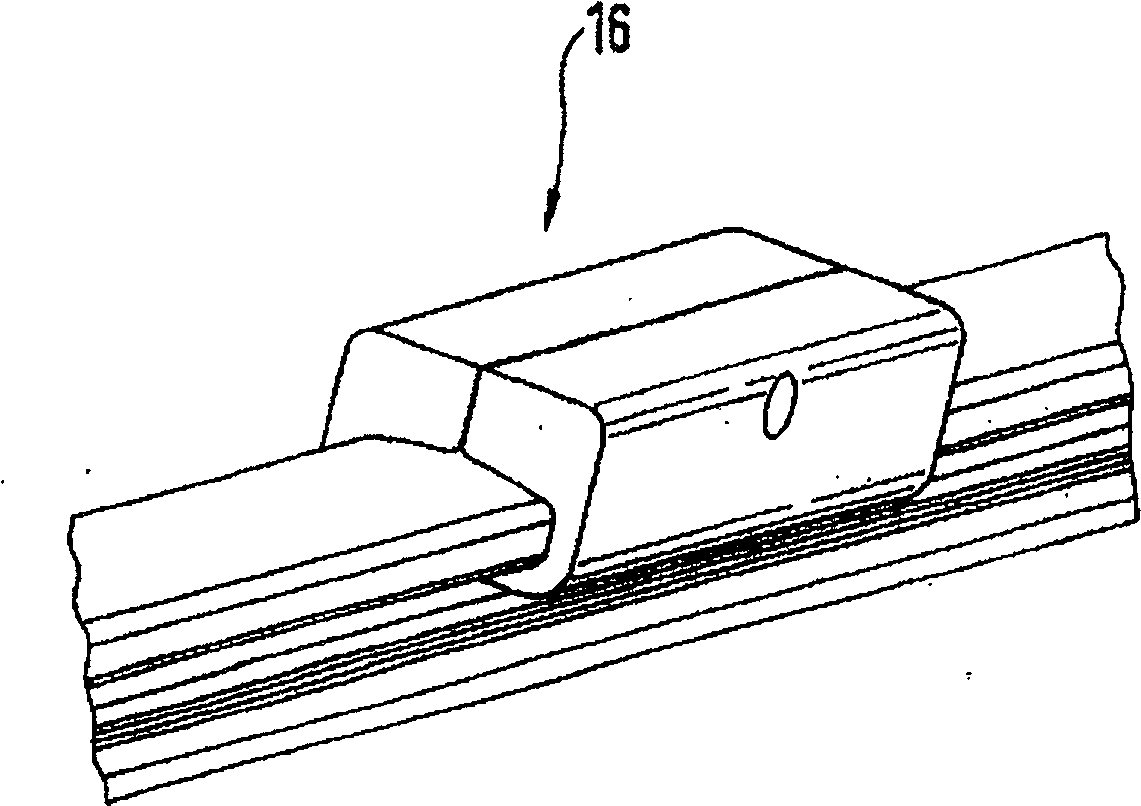

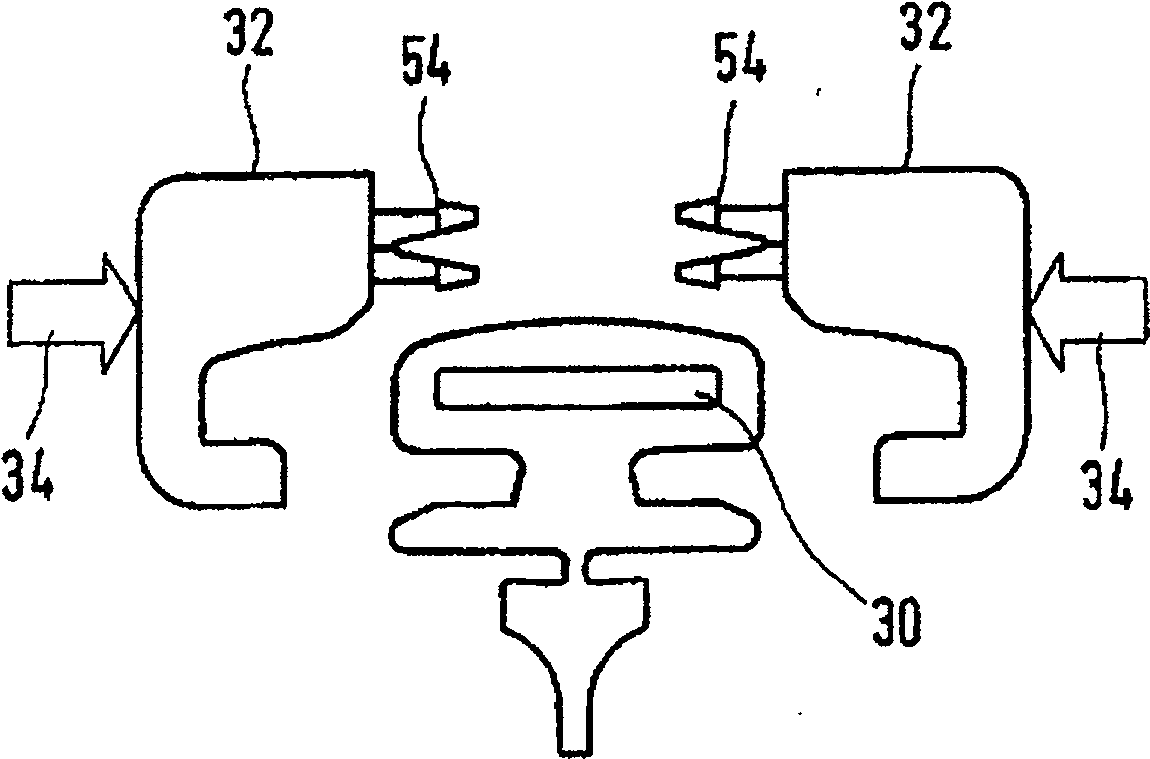

[0027] exist Figure 15 shows a wiper blade 10 according to the invention, it has a wiper strip 12, a bracket 14, the bracket is for example in Figure 5 The wiper blade also has a connecting device 16 for connecting a wiper arm 18 via a hinge shaft, as shown in a sectional view in FIG. By means of the wiper arm 18 the wiper blade 10 can be guided on the glass 22 to be wiped, the glass Figure 15 Indicated by dotted lines. exist Figure 15 The middle wiper blade 10 has not yet been completely erected on the glass 22 , and only the end 24 of the wiper blade bears against the glass 22 when the wiper strip 12 is still at a distance from the glass 22 at the connecting device 16 . The wiper strip 12 is pressed against the glass 22 by the clamping force of the bracket 14 when a predetermined contact pressure is exerted on the connecting device 16 via the wiper arm 18 . This clamping force by the bracket 14 ensures a uniform contact pressure over the entire length of the wiper bl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com