Tool for connecting cable conductors

A technology for connecting cables and cable core wires, which is applied in the field of tools for connecting cable conductors, and can solve problems such as forgetting to reinstall safety connectors and inconsistent procedures

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

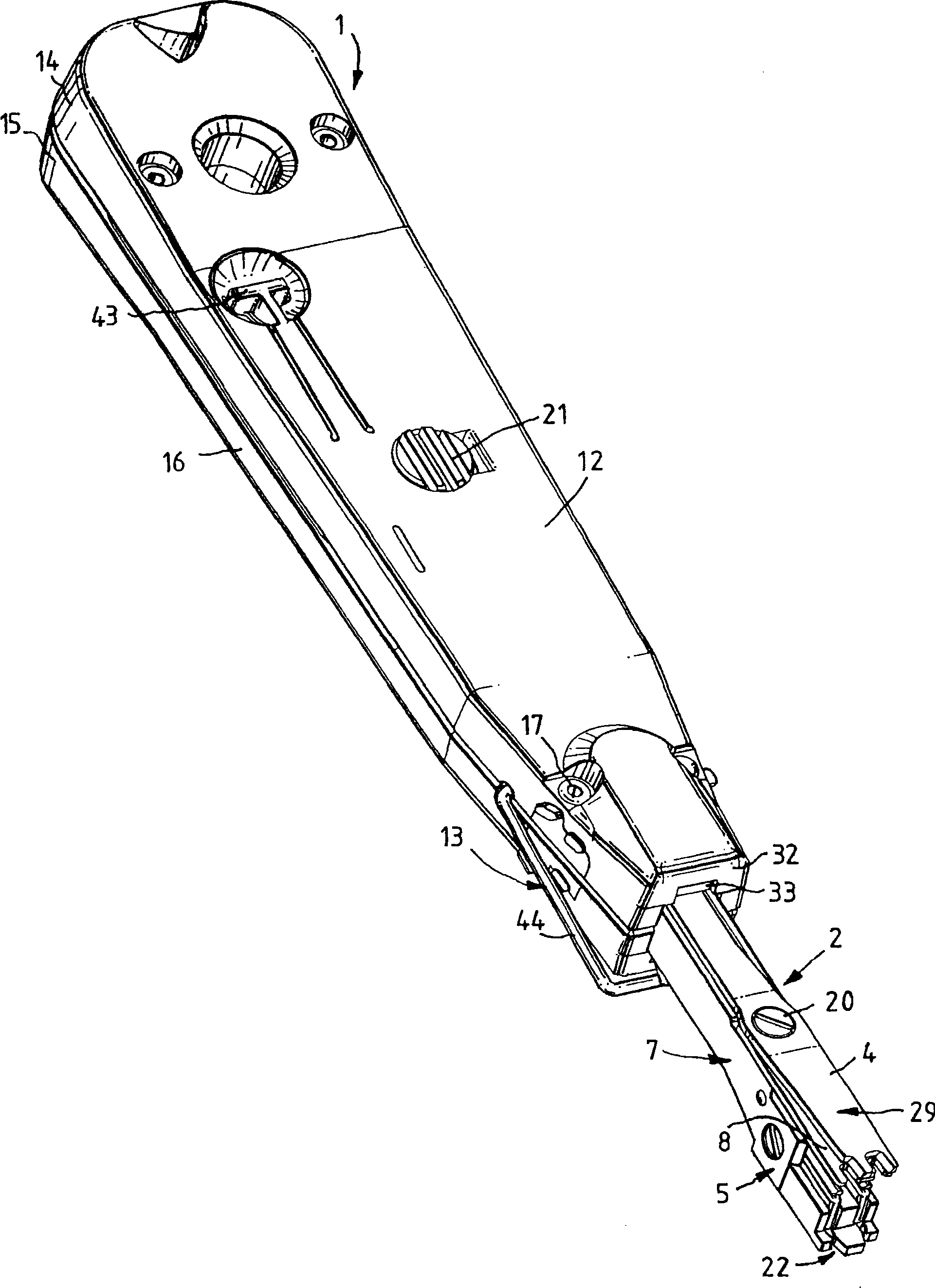

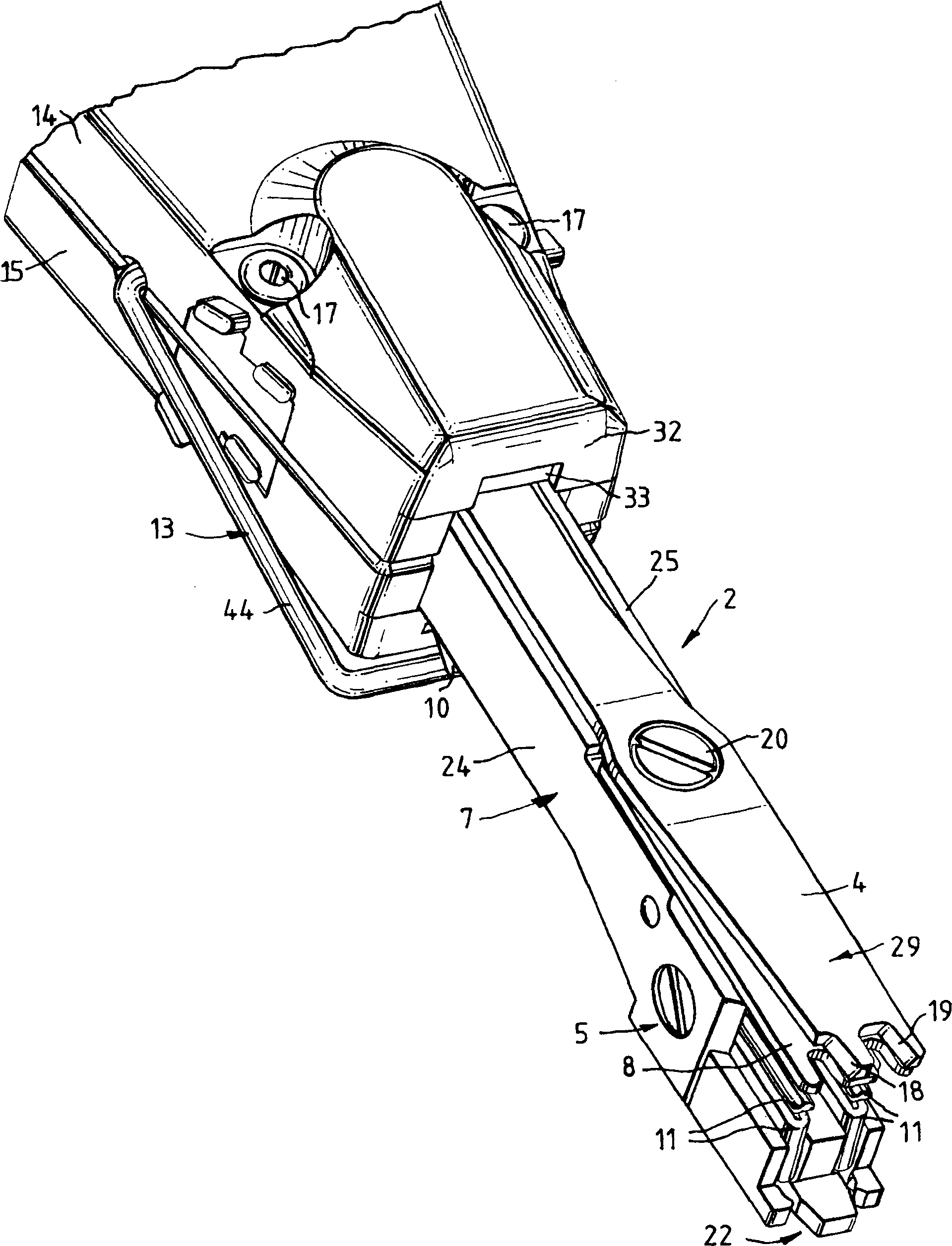

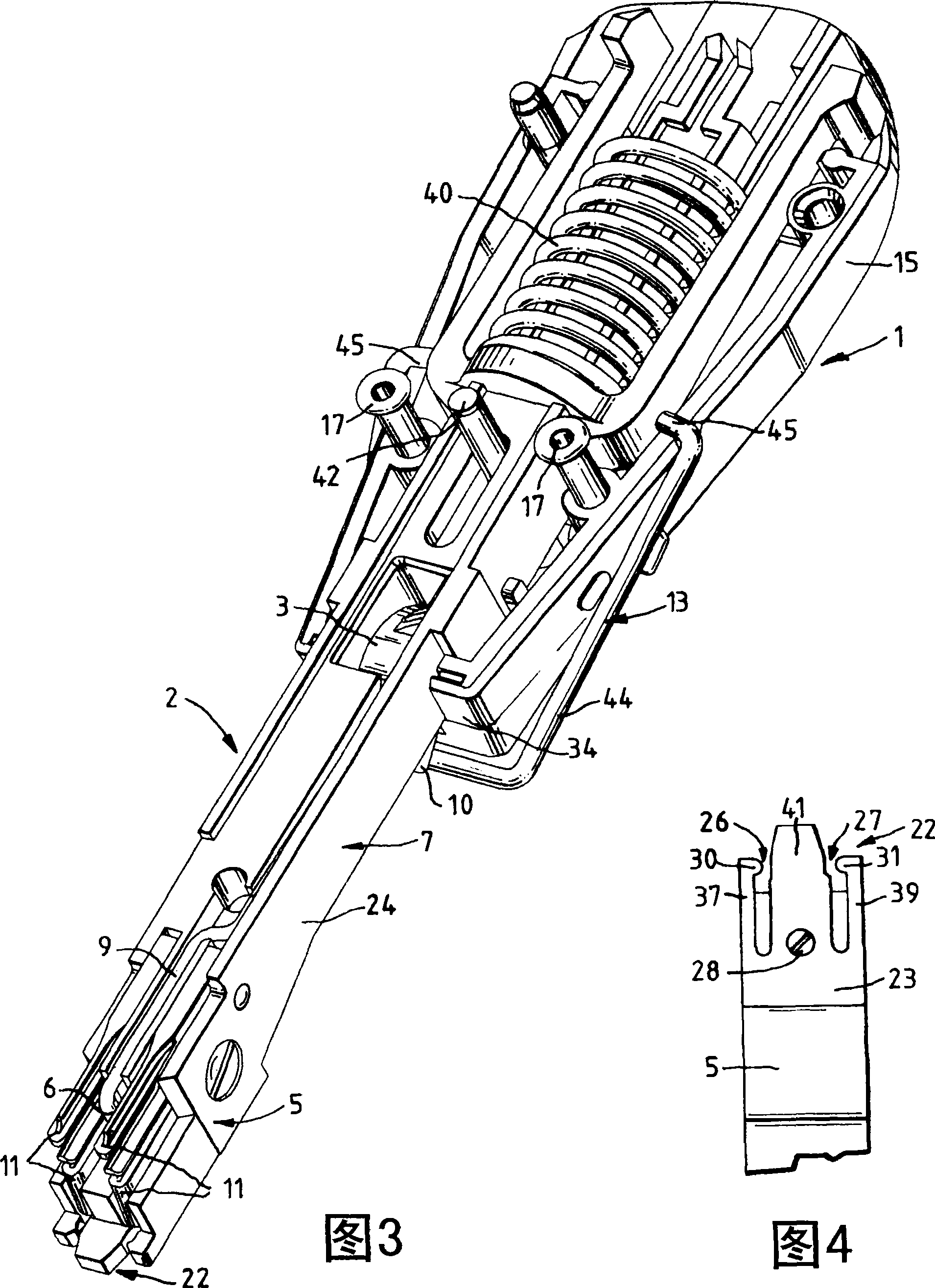

[0035] figure 1 A tool 1 is shown comprising a tool housing 12 consisting of two plastic half-shells 14 , 15 and forming a clamp 16 . The two housing half-shells 14 , 15 are connected to each other by screws 17 . The longitudinally movable ram 2 is arranged in the clamp 16 provided with an opening 33 on one end face 32 , the ram has a striking mechanism and protrudes from the opening 33 in the end face 32 of the tool housing 12 . The part of the ram 2 protruding from the tool 1 includes a ram tool holder 5 located at the front end of the ram 2 and a ram handle 7 located between the ram tool holder 5 and the opening 33 of the tool housing. A cutter 29 for cutting the cable core is arranged on the ram knife holder, and the longitudinal displacement of the ram 2 is used to trigger the cutting operation. The cutter 29 in this case comprises two shearing blades 4, 8 which are relatively movable and which are laid flat one above the other on the ram tool holder 5, the inner sheari...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com