Pressure test method for detecting seal performance of gas storage cavity of salt cavern

A gas storage and airtightness technology, which is applied in the liquid tightness measurement using liquid/vacuum degree, by measuring the increase and deceleration rate of the fluid, construction, etc., can solve the problem of long test time, poor field operability, and indeterminate leakage Position and other issues, to achieve the effect of scientific and accurate evaluation method, strong on-site operability, and reduced pressure test cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

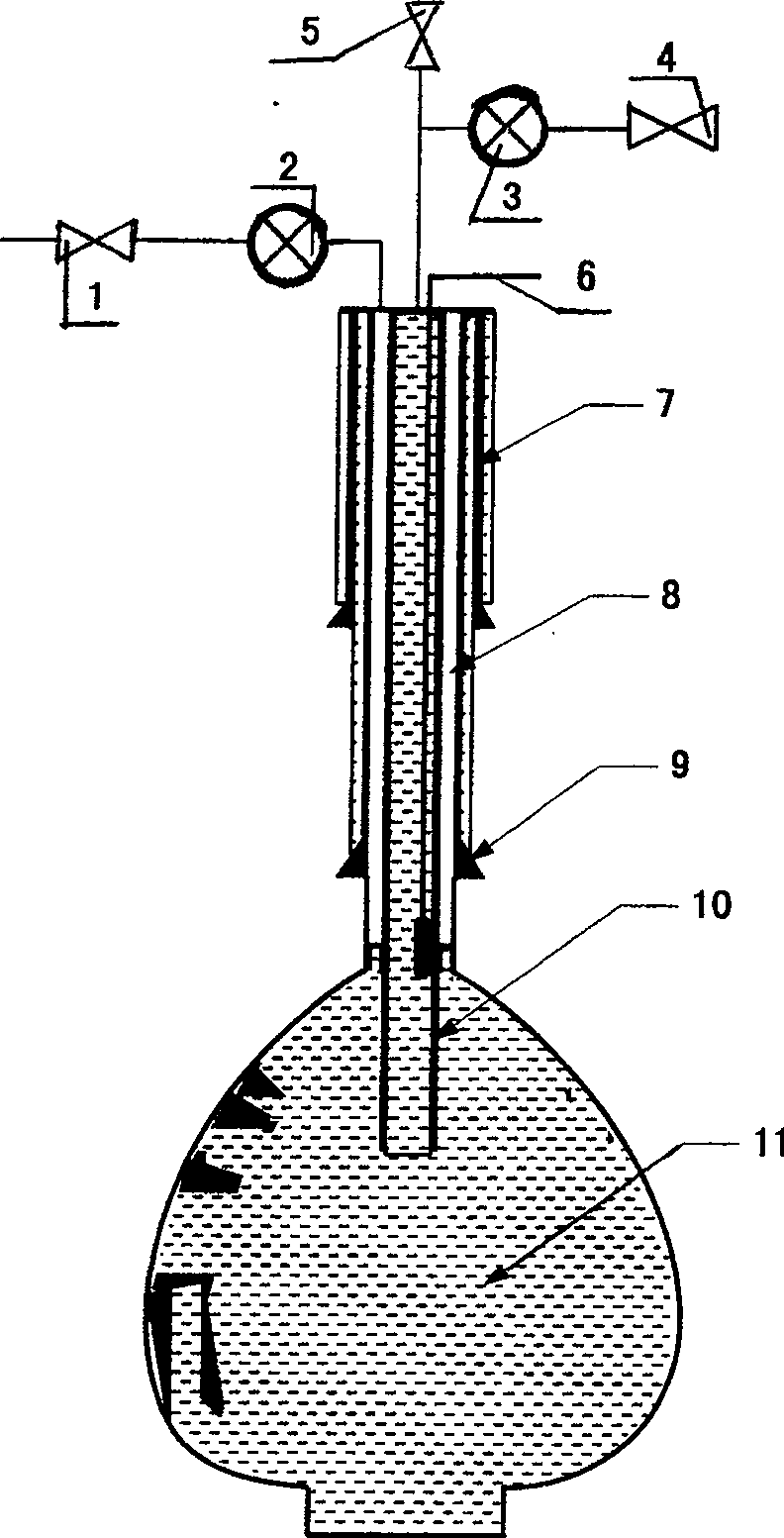

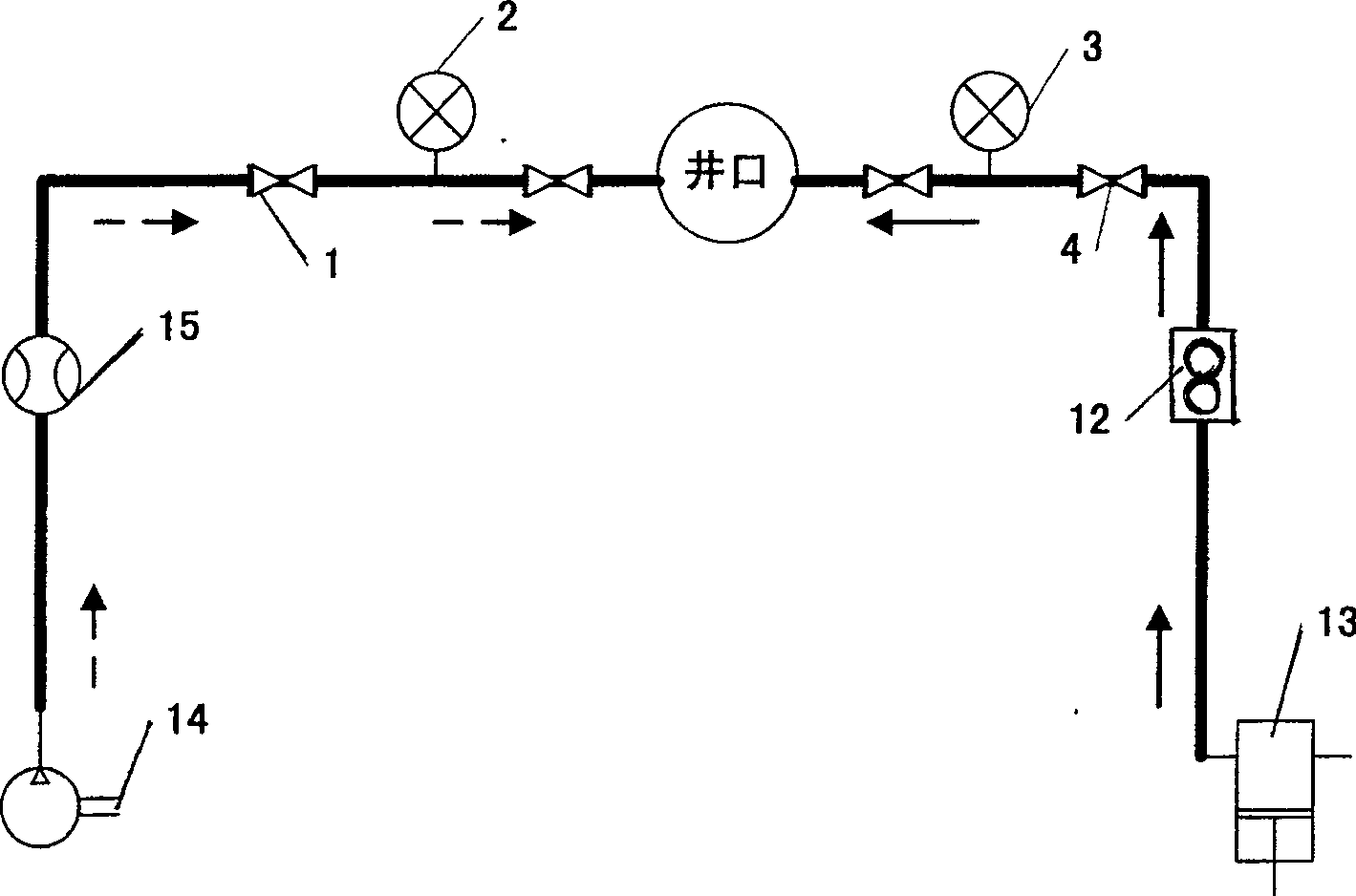

Method used

Image

Examples

Embodiment Construction

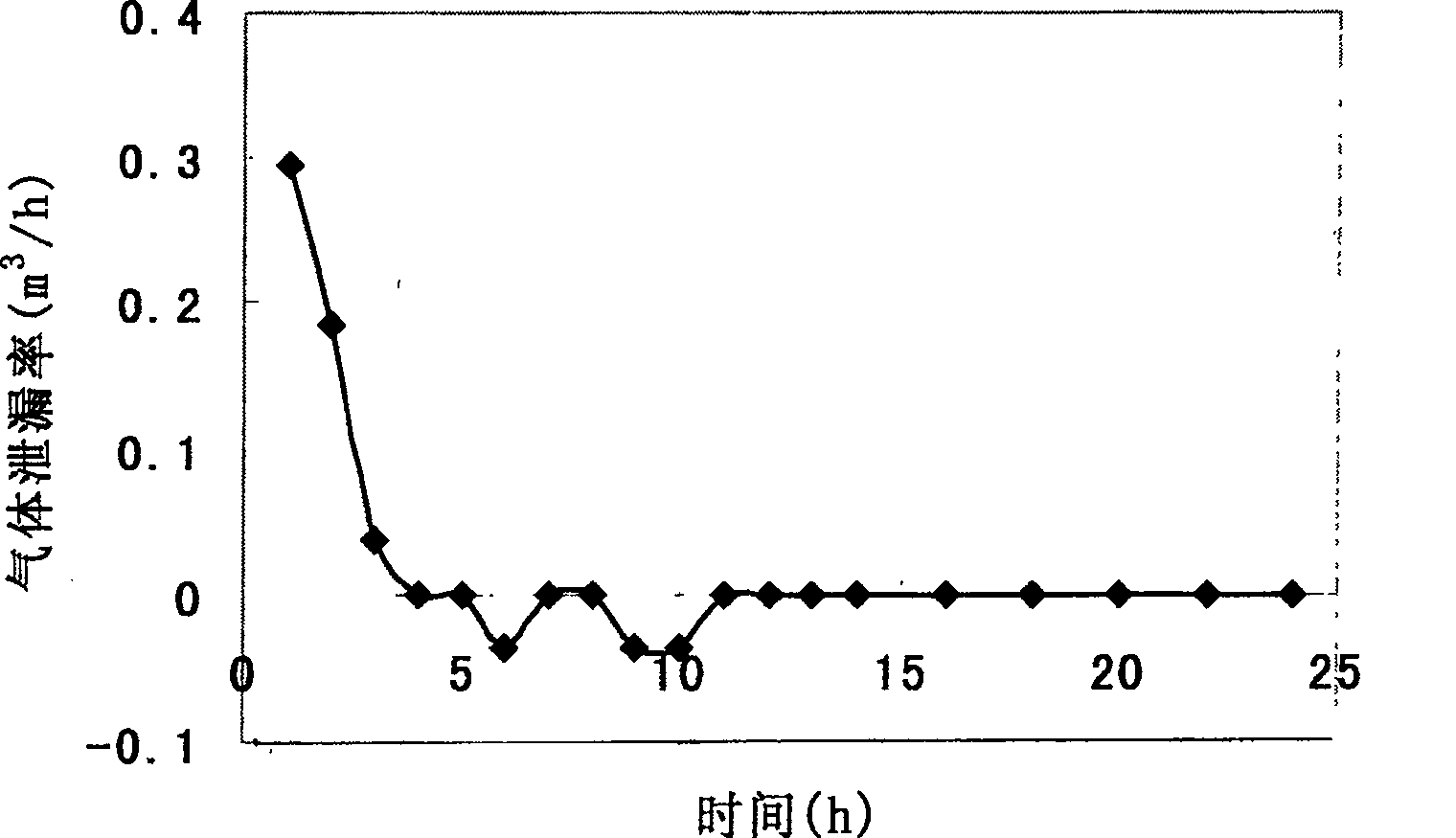

[0027] This method has been successfully tried for the first time in the pressure test process of the salt cavern cavity of West 2 Well and West 1 Well in Jintan area, which belongs to our company, from December 12th to 15th, 2004. The whole pressure test process was very smooth. The pressure test results show that within 24 hours, the maximum variation of the gas-water contact depth at the production casing shoes of Wells Xi 1 and Well Xi 2 is 0.118m, and the cavity leakage rate of Wells Xi 1 and Well Xi 2 gradually decreases over time. Small, and finally stabilized at around 0 value, so the cavities of the salt cavern gas storage in Wells Xi 1 and Well Xi 2 are well sealed, and the next stage of gas injection and brine discharge can be carried out. The successful pressure tests of Wells Xi 2 and Well Xi 1 were highly recognized by peer experts, and the pressure test methods were unanimously praised by experts. This method was successfully applied in the pressure test of Well...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com