Uncoiler drum of cold rolled coil

A technology of machine coils and steel coils, which is applied in the field of metallurgical machinery and cold-rolled steel coil uncoilers. It can solve the problems of not meeting the technical requirements of uncoilers, large reciprocating strokes of push-pull rod drive mechanisms, and inconvenient practical operations. , to achieve the effect of light weight, compact structure, practical operation, simple and convenient

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0030] Hereinafter, the present invention will be further explained through the description of specific embodiments with reference to the accompanying drawings.

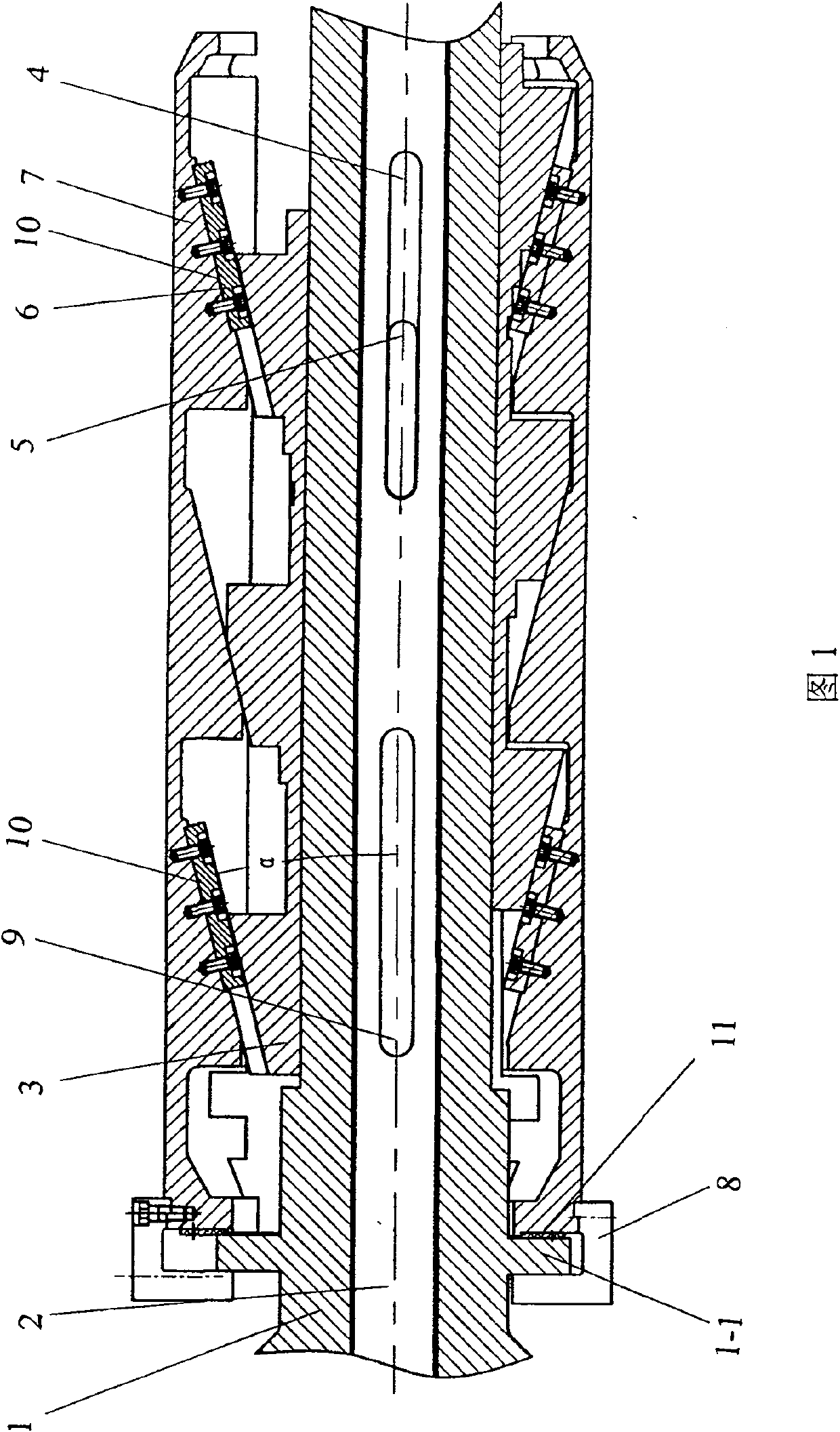

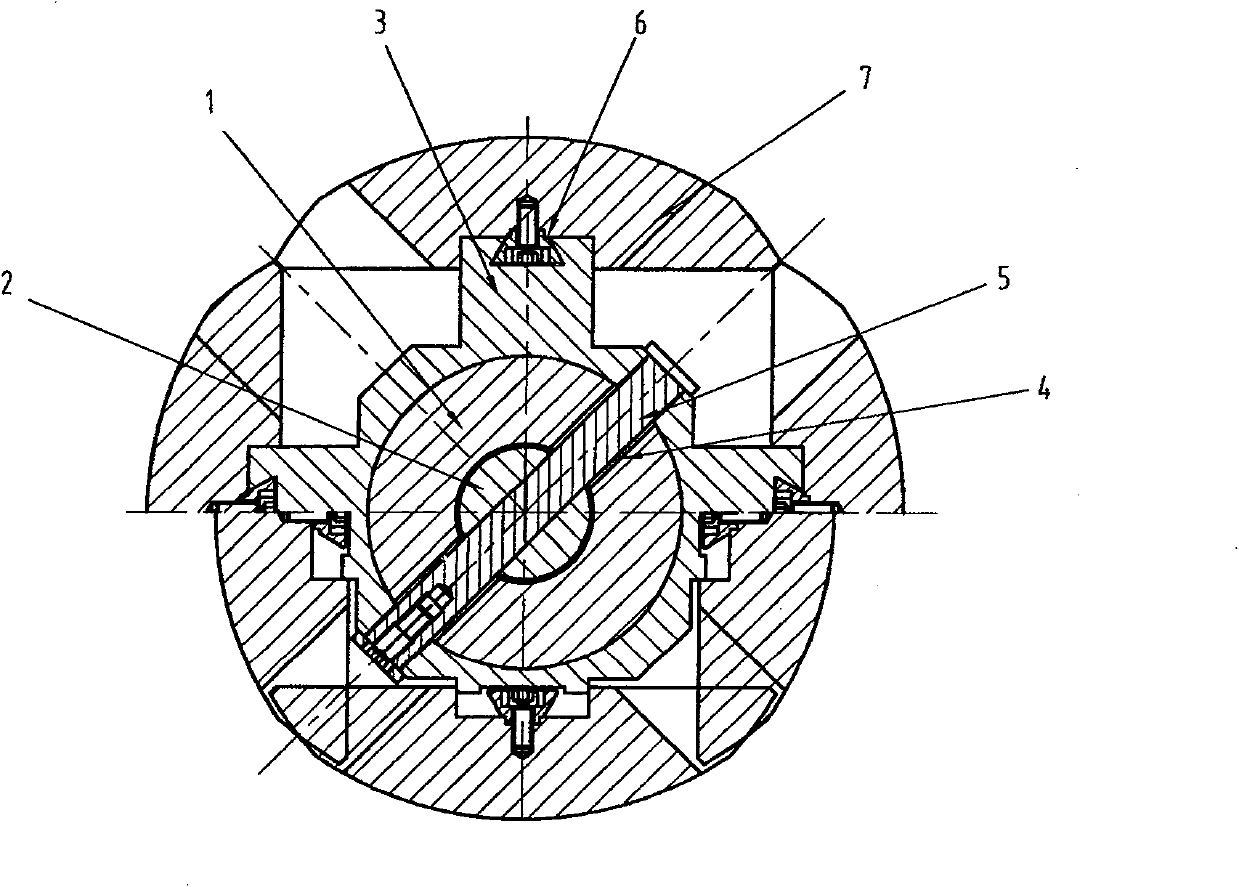

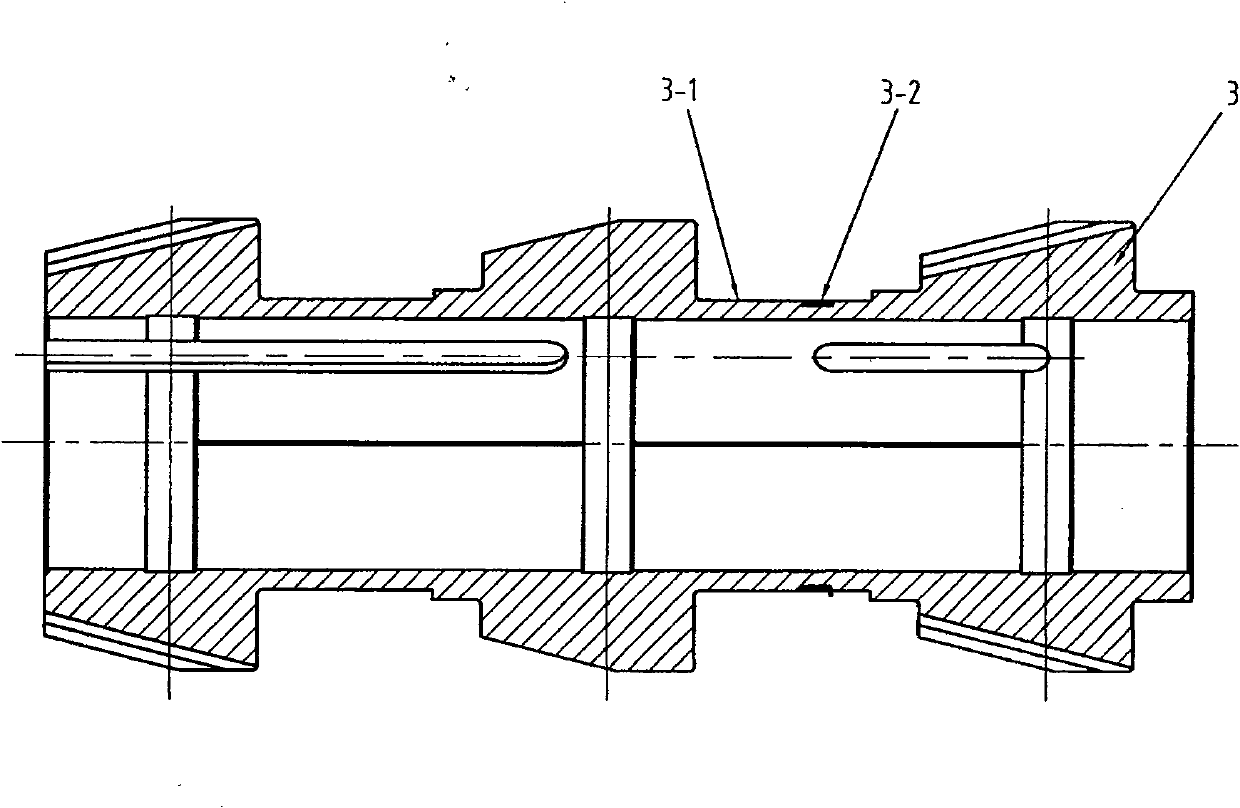

[0031] A typical specific implementation is shown in Figures 1 to 4.

[0032] A cold-rolled steel coil decoiler drum, comprising a hollow mandrel 1 provided with two symmetrical long slots 4 along the axial direction, a push-pull rod 2, a multi-stage external oblique wedge structure and a pyramid with at least 2 edges Sleeve 3, over key 5, multi-level internal oblique wedge structure with the same number of edges as the pyramid sleeve 3, and segment plate 7 and clamping block 8 that can be matched with the outer oblique wedge of the pyramid sleeve 3; the hollow mandrel 1 can be uncoiled The power output shaft of the rotating assembly of the machine is coaxially connected; the push-pull rod 2 can be connected with the reciprocating power unit and is arranged in the hollow shaft 1 and can slide along the axial direction; t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| pore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap