Method for manufacturing substrate with emergent points

A manufacturing method and technology of bumps, which are applied in the field of manufacturing substrates with bumps, can solve problems such as difficult bumps, inability to install circuit components at the same time, and inability to select the height of bumps 108, etc., to achieve reliable electrical connection and manufacturing process The effect of simplicity and high reliability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

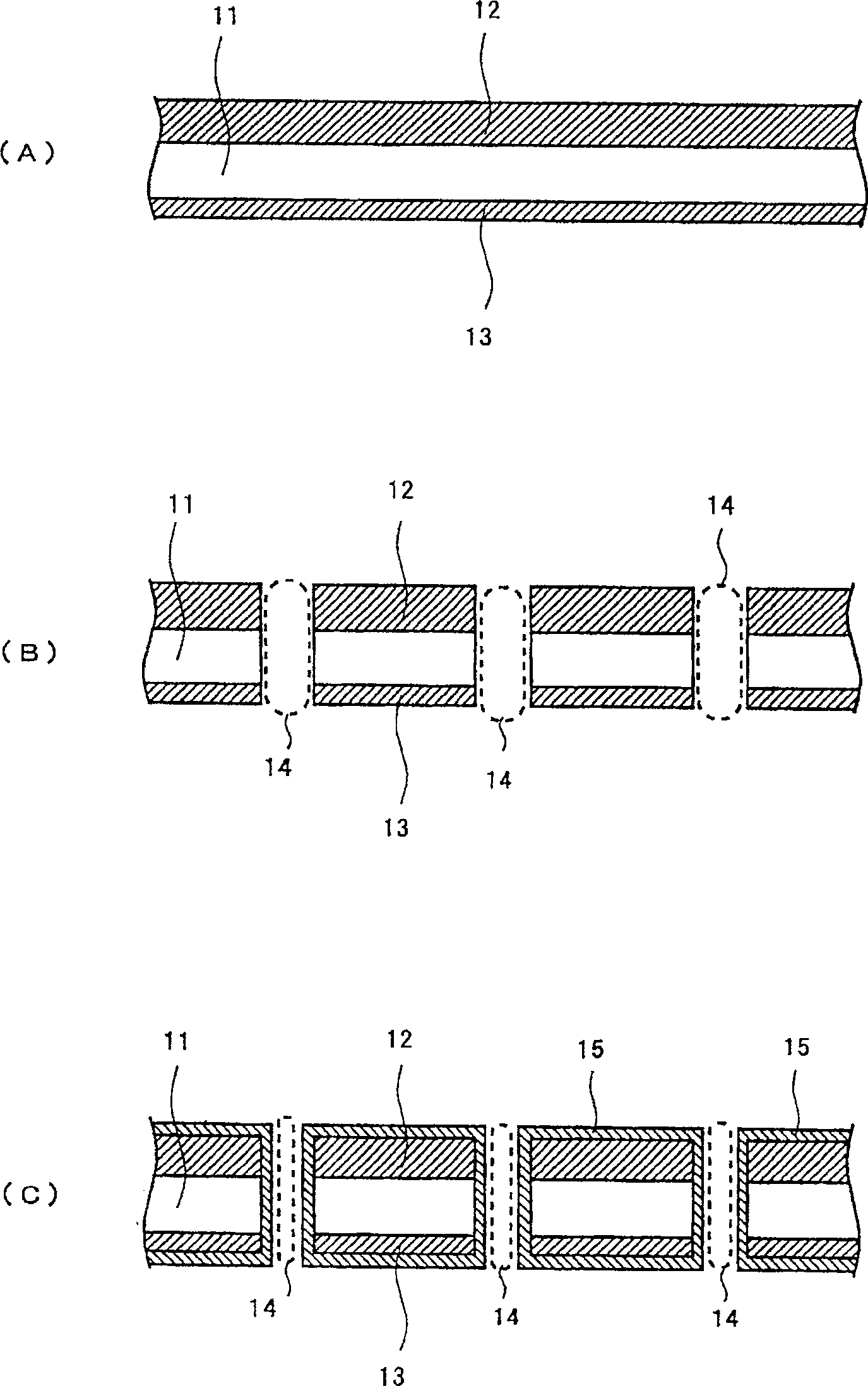

[0048] refer to Figure 1 ~ Figure 3 The method of manufacturing the circuit board of this embodiment will be described.

[0049] First, refer to figure 1 (A), the substrate 11 with the first conductive foil 12 pasted on the top and the second conductive foil 13 pasted on the bottom is prepared.

[0050] As the substrate 11, a glass epoxy substrate or a glass polyimide substrate is preferably used, but a fluorine substrate, a glass PPO substrate, a ceramic substrate, etc. may also be used depending on circumstances. In addition, flexible boards, films, and the like can also be used. In this embodiment, a glass epoxy substrate having a thickness of approximately 200 μm is used.

[0051] As the first conductive foil 12 and the second conductive foil 13, any metal that can be etched may be used. In this form, metal foil made of copper is used. Furthermore, copper foil having a film thickness of about 175 μm is used for the first conductive foil 12 . This film thickness is ...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap