Method for carving leaves through laser

A laser engraving machine, laser technology, applied in decorative arts, crafts for producing decorative surface effects, special decorative structures, etc. Unique artistic charm, short production cycle, simple operation effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

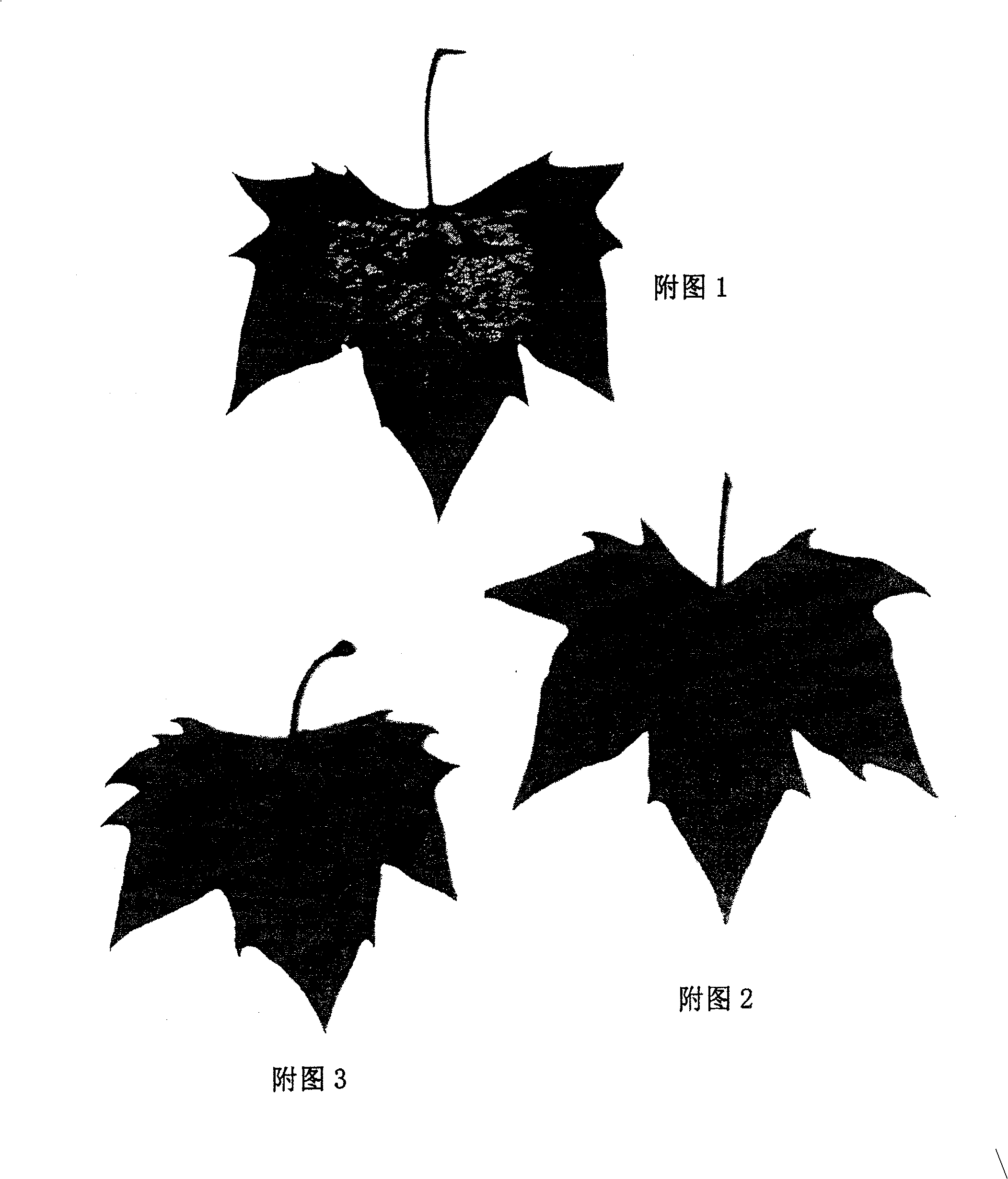

[0010] Embodiment 1: (1) select the red maple leaf that has just fallen intact and not yet dry: (2) place the selected red maple leaf between the two platens of the blade flattener and flatten it, then take it out and air-dry it to disperse the water (3) Input the designed pattern into the computer with a scanner, and then place the red maple leaf to be engraved on the engraving machine of the laser engraving machine. on the platform, and then start the laser engraving machine for engraving, using a laser power of 30 watts and an engraving speed of 1000 mm / s. One of the engraved works is attached figure 1 , the mesophyll is hollowed out, and the veins are basically preserved.

Embodiment 2

[0011] Embodiment 2: Use laser power of 10 watts, engraving speed of 800 mm / s, other same as embodiment 1. One of the engraved works is attached figure 2 , the mesophyll is basically removed, and the veins are all preserved.

Embodiment 3

[0012] Embodiment 3: use laser power of 60 watts, engraving speed of 1500 mm / s, other same as embodiment 1. One of the engraved works is attached image 3 , the mesophyll is basically removed, and the veins are all preserved.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com