Texture air layer knitted fabric and manufacturing method and application thereof

A knitted fabric and air layer technology, applied in the field of textile fabrics, can solve the problems of single surface effect and popularization, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0052] This embodiment provides a kind of texture air layer knitted fabric, which is made by a production method comprising the following specific steps:

[0053] Yarn pretreatment→knitting and weaving process→cloth inspection (open width and rolling)→cloth preparation→singeing→pre-setting (1 time)→enzyme washing→dyeing (piece dyeing) or washing (yarn dyeing)→dehydration→manipulation→ Drying→intermediate inspection→setting (oversoft oil)→post-inspection;

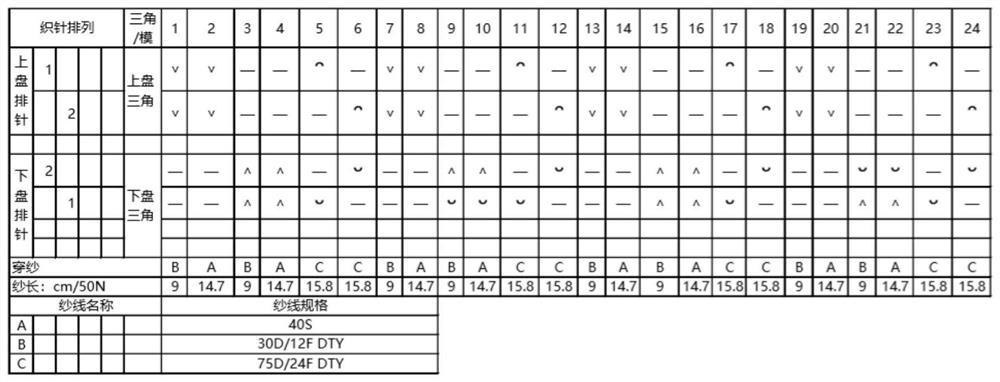

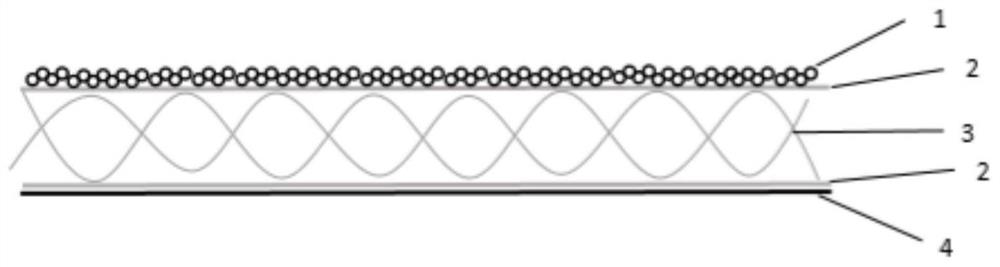

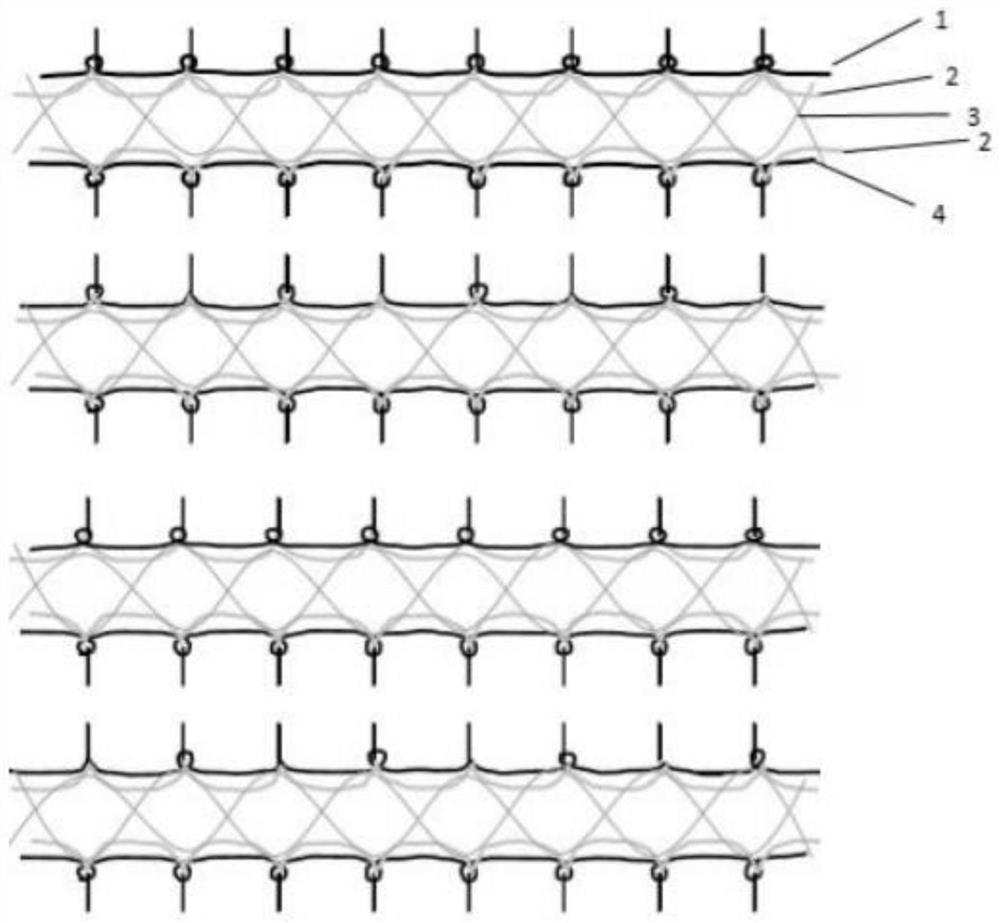

[0054] Wherein, the knitting and weaving process adopts the 24-mode weaving method, and the structure diagram of the upper machine is as follows: figure 1 As shown, among them, the knitting needles of the upper and lower disks are arranged in position, the 1st, 7th, 13th, and 19th molds, the upper disk wears the second spinning yarn and all the needles are released, and the yarn pressing sheet assists in not forming a loop; the 2nd, 8th, 14th, and 20th molds, Wear the third spinning yarn on the upper plate to form a loop an...

Embodiment 2

[0072] This embodiment provides a kind of texture air layer knitted fabric, which is made by a production method comprising the following specific steps:

[0073] Yarn pretreatment→knitting and weaving process→cloth inspection (open width and rolling)→cloth preparation→singeing→pre-setting (1 time)→enzyme washing→dyeing (piece dyeing) or washing (yarn dyeing)→dehydration→manipulation→ Drying→intermediate inspection→setting (oversoft oil)→post-inspection;

[0074] Wherein, the knitting and weaving process adopts the 24-mode weaving method, wherein the knitting needles of the upper and lower discs are arranged in position, the 1st, 7th, 13th, and 19th modes, the upper disc wears the second spinning yarn and all the needles are released, and the yarn pressing sheet assists in not forming a loop; The 2nd, 8th, 14th and 20th molds, the upper plate wears the third spinning yarn to form a loop, and forms a loop together with the upper mold, that is, the 1st, 7th, 13th, and 19th molds...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com