Rear axle axle sleeve and sealing structure between differential gear axle shaft gear

A technology of half-shaft gear and sealing structure, which is applied in the direction of engine sealing, engine components, mechanical equipment, etc., to achieve the effect of improving service life and sealing reliability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0008] Below in conjunction with accompanying drawing and embodiment the present invention will be further described:

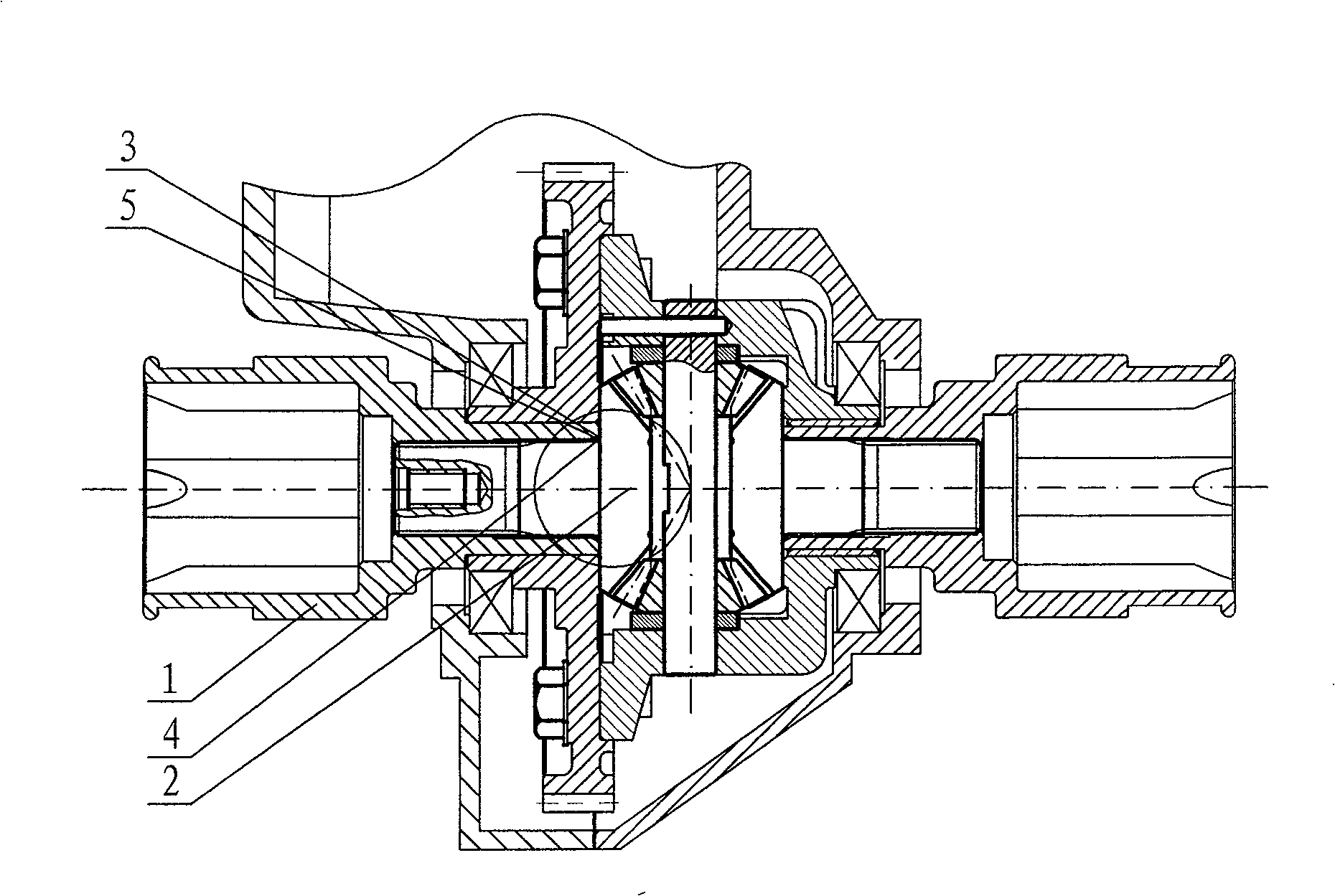

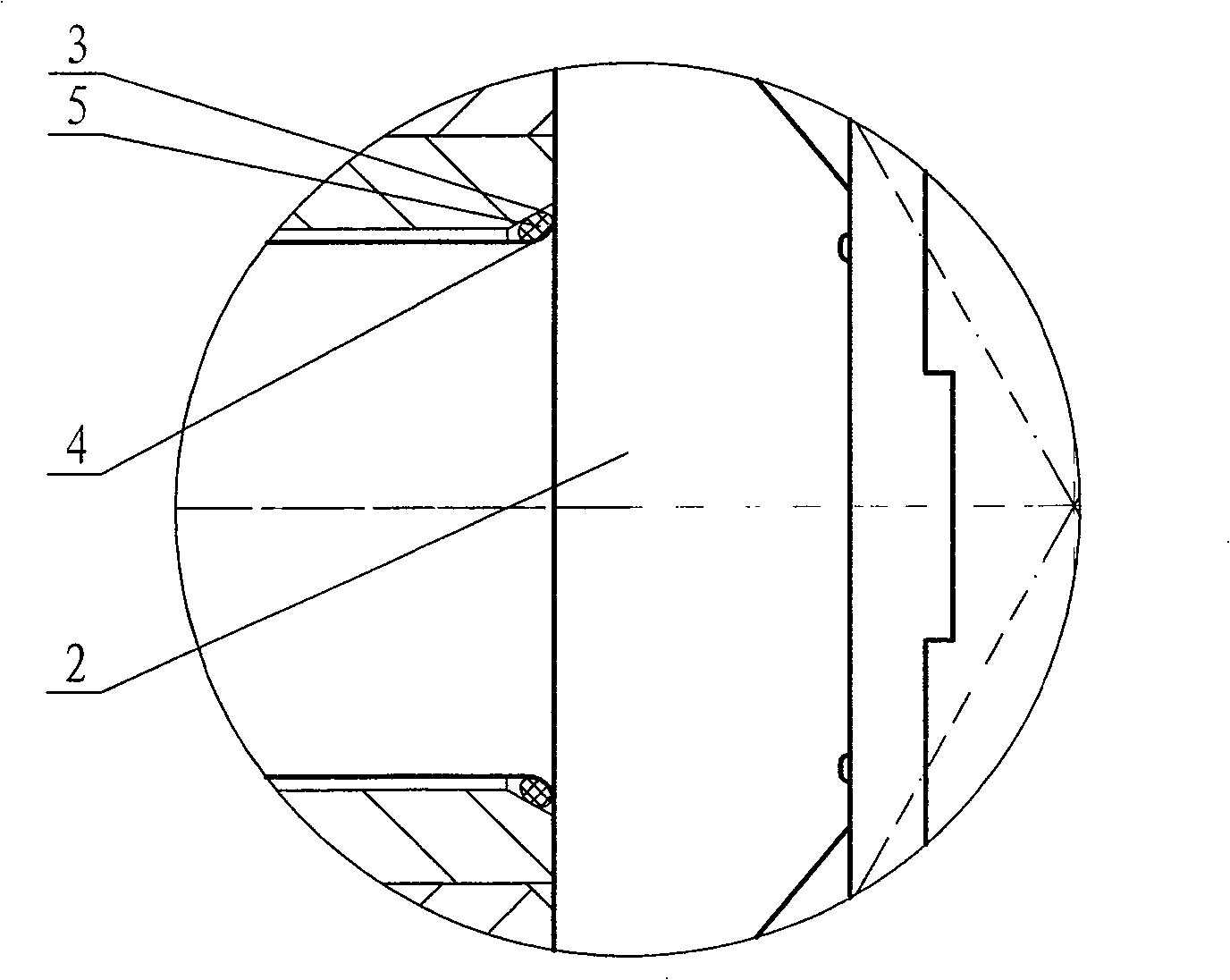

[0009] Such as figure 1 , figure 2 As shown, in the sealing structure between the rear axle sleeve and the differential side gear provided by the present invention, the journal of the side gear 2 is located in the shaft sleeve 1, and the shaft sleeve 1 is axially connected to the end of the side gear 2 The chamfering of the inner edge of the face-to-face contact end forms a bevel 3 , and a sealing ring 5 is arranged between the bevel 3 and the journal root 4 of the side gear 2 . After the inner edge of the contact end of the shaft sleeve 1 and the side gear 2 is chamfered to form a bevel 3, the sealing ring 5 is arranged between the bevel 3 and the journal root of the side gear 2, which solves the problem The sealing problem does not affect the firmness of the connection between the shaft sleeve 1 and the side gear 2, and the sealing ring 5 will not be wor...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com