Bowling alley device

A bowling lane, bowling ball technology, applied in bowling, transportation and packaging, thin material handling, etc., can solve the problems of non-coplanarity, coplanarity, and inability to adapt to differences in mechanical properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

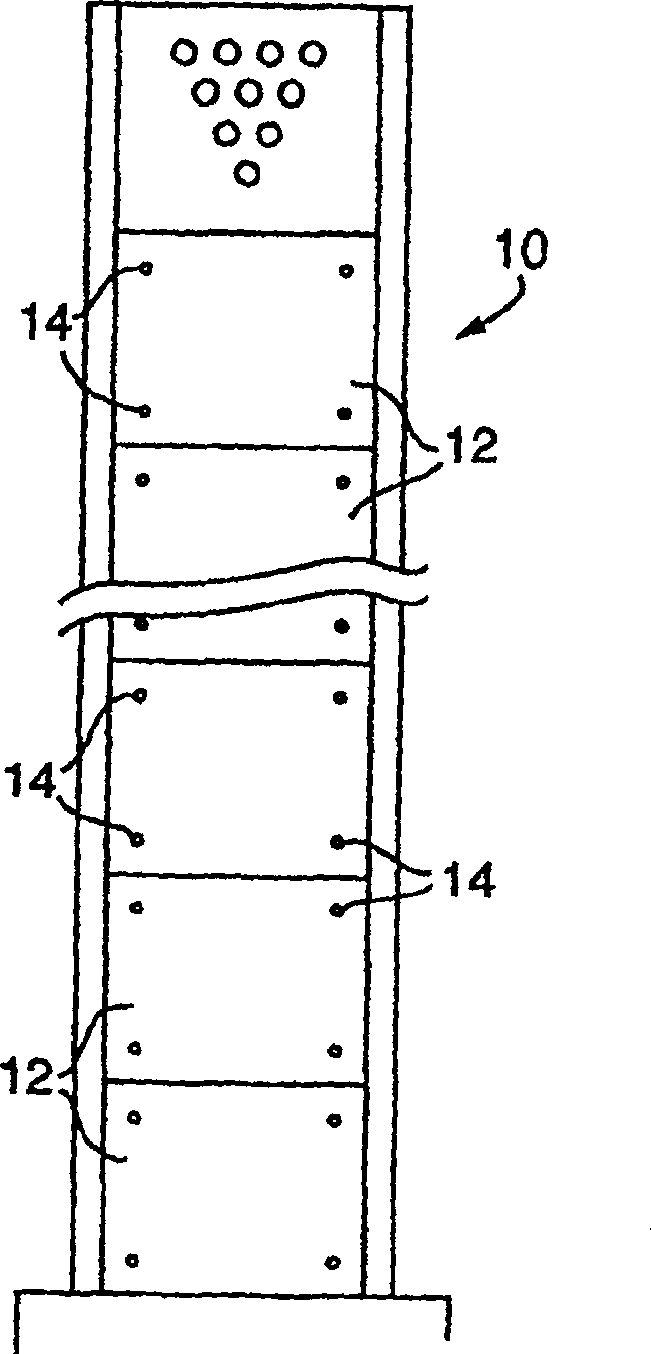

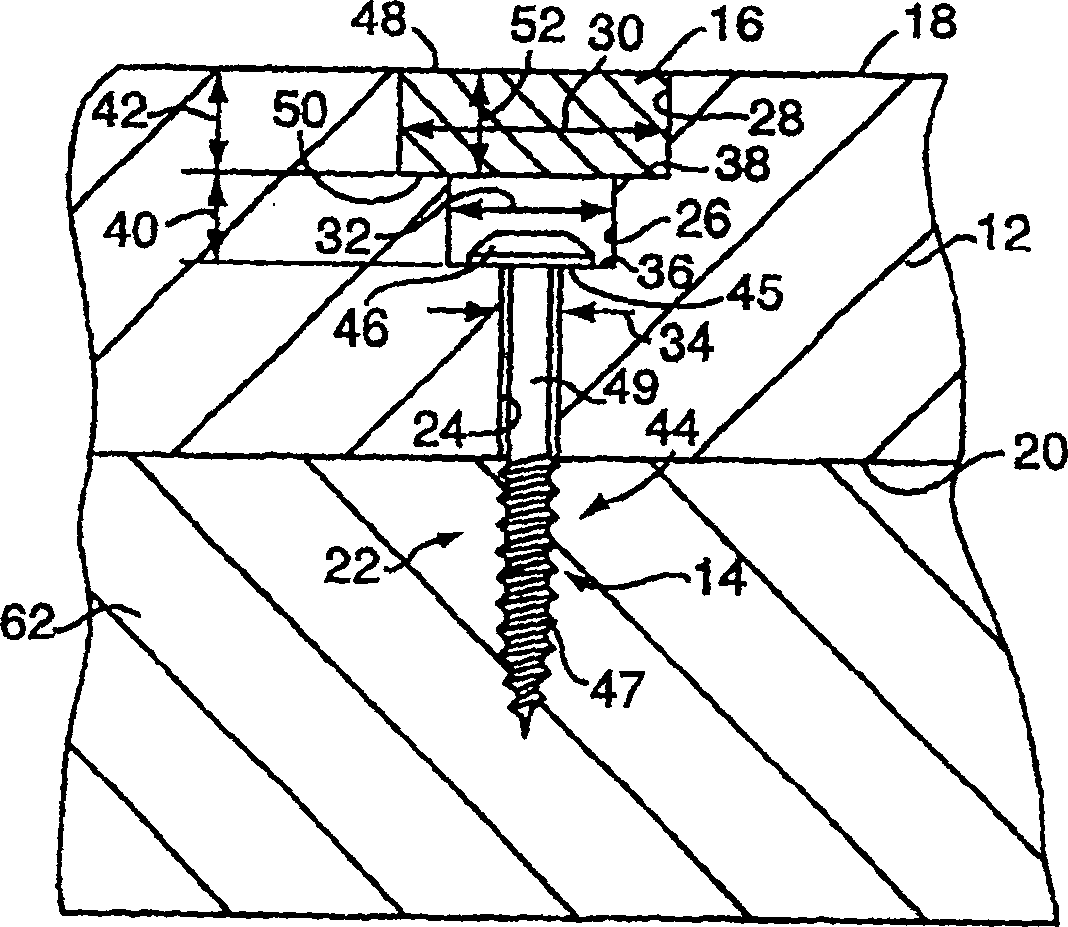

[0015] refer to figure 1 -3. A bowling lane 10 of the present invention includes one or more lane sections 12 , a plurality of fasteners 14 and a plurality of plugs 16 . Each of the one or more fairway segments 12 has a first surface 18 , a second surface 20 and a plurality of connection points 22 . In one embodiment, each connection point 22 has a first hole 24, a second hole 26, and a third hole 28, all three holes being substantially concentric and each having a diameter. The first aperture 24 extends between the second surface 20 and the second aperture 26 . The second hole 26 extends between the first hole 24 and the third hole 28 . The third aperture 28 extends between the second aperture 26 and the first surface 18 . The diameter 30 of the third hole 28 is larger than the diameter 32 of the second hole 26 which is larger than the diameter 34 of the first hole 24 . A first shoulder 36 extends substantially radially between the first hole 24 and the second hole 26 , a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com