Apparatus for direct oxidization of propane with molecular oxygen to prepare propane epoxide

A technology of propylene oxide and molecular oxygen, which is applied in the field of devices for the direct oxidation of propane and molecular oxygen to prepare propylene oxide, can solve the problems of sensitive process conditions and difficulty in repeating experimental results, and achieve cheap and clean raw materials, good industrial application prospects, No equipment corrosion effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

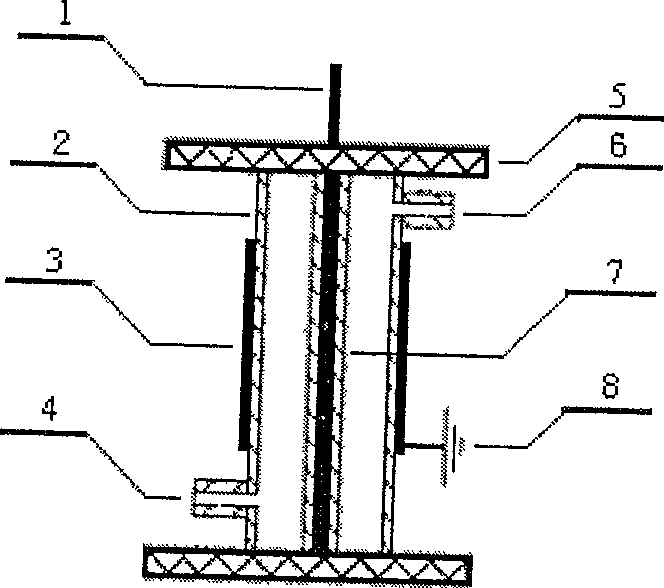

[0021] Propane with a purity of ≥99.99% and oxygen gas in an ordinary steel cylinder with a purity of ≥99% are regulated by a gas mass flowmeter and mixed uniformly in a mixer, in which propylene accounts for 1.0%, and then enter the reactor from the feed gas inlet 4 to replace the air After 5 minutes, switch on the AC high-voltage power supply to conduct dielectric barrier plasma discharge. The raw material gas reacts in the annulus formed between the inner cylinder 7 and the outer cylinder 2, and the product is detected and analyzed at the product gas outlet 6. The housing of the device of the present invention is made of oxide hard glass, wherein the outer diameter of the inner cylinder 7 is 3.5 millimeters, the wall thickness of the inner cylinder 7 is 1.5 millimeters, and the distance between the annular gap between the inner cylinder 7 and the outer cylinder 2 is 5 mm. mm, the length of the discharge area is 150 mm. The device of the present invention uses a copper wire ...

Embodiment 2

[0023] Repeat Example 1, when the volume ratio of propane / oxygen was 1.5%, the reaction result obtained under different discharge voltages was: when the discharge voltage was 15.6kV, the conversion of propane was 8.4%, and the selectivity of propylene oxide It was 6.6%; when the discharge voltage was 18.3kV, the propane conversion rate was 24.9%, and the selectivity of propylene oxide was 8.9%; when the discharge voltage was 20.5kV, the propane conversion rate was 30.1%, and the selectivity of propylene oxide was 7.2%.

Embodiment 3

[0025] Repeat Example 1, change the volume ratio of propane / oxygen in the raw material gas, the reaction result that obtains is: when the volume ratio of propane / oxygen is 0.5%, the conversion of propane is 39.2%, and the selectivity of propylene oxide is 5.1% ; When the volume ratio of propane / oxygen was 1.5%, the propane conversion rate was 25.8%, and the selectivity of propylene oxide was 7.6%; when the volume ratio of propane / oxygen was 2.0%, the propane conversion rate was 19.6%, and the The selectivity to oxypropane was 9.4%.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com