Device for directly preparing propionaldehyde from propane and oxygen under alternating electric field

An alternating electric field and propane technology is applied in the preparation of carbon-based compounds, the preparation of organic compounds, chemical instruments and methods, etc., to achieve mild reaction conditions, no equipment corrosion, and good industrial application prospects.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

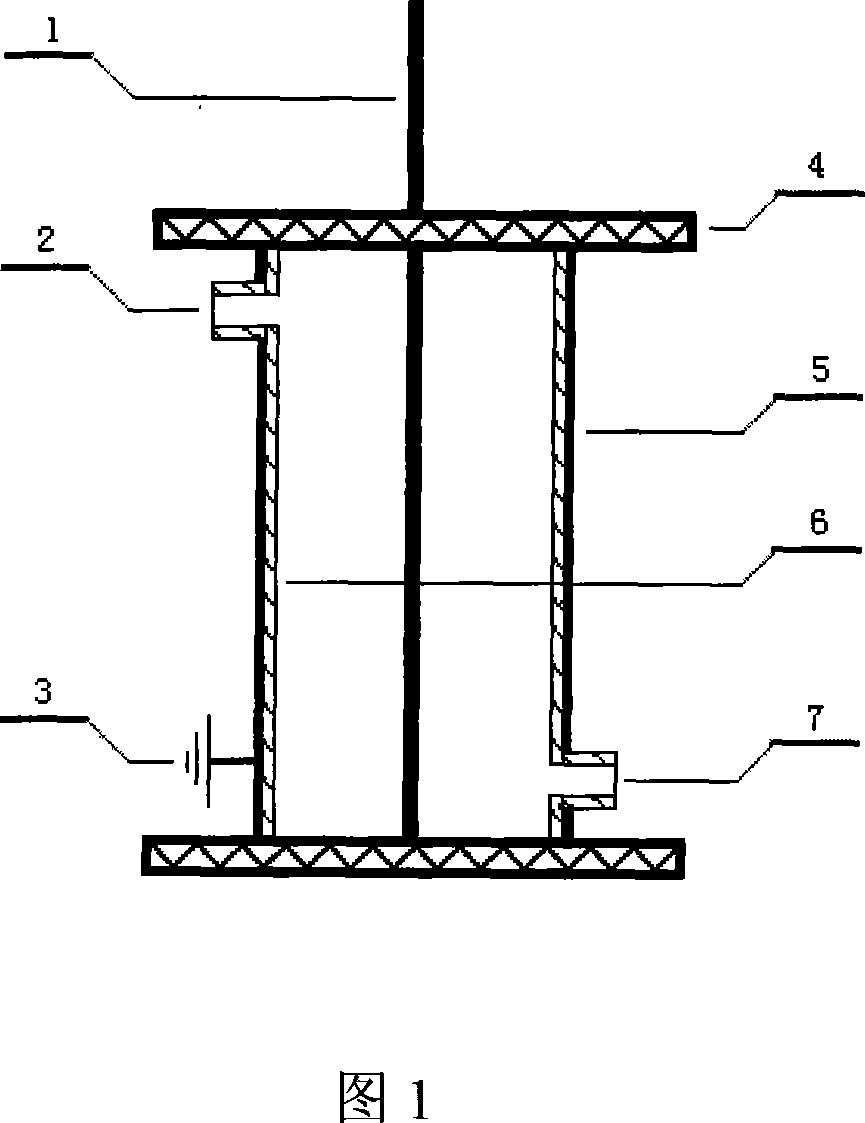

Image

Examples

Embodiment 1

[0017] Propane, purity ≥ 99.99% and oxygen ordinary cylinder gas, purity ≥ 99% are regulated by the gas mass flow meter, and mixed uniformly in the mixer at an appropriate flow rate respectively. The volume ratio of propane and oxygen is 1.2%, and then from the raw material gas The inlet 2 enters the reactor, and after the air is replaced for 5 minutes, the AC high-voltage power supply is connected to conduct dielectric barrier plasma discharge, and the product detection and analysis are carried out at the product gas outlet 7. The reactor barrel 6 of the device of the present invention is made of oxide hard glass, its outer diameter is 15 mm, the wall thickness is 1.5 mm, and the length of the discharge zone is 160 mm. The device of the present invention uses a copper wire with a smooth surface as the discharge electrode, the outer diameter of which is 1.2 mm, and the ground electrode is a copper mesh. Under the conditions of a voltage of 21.0kV and a frequency of 1.0kHz, the...

Embodiment 2

[0019] Repeat Example 1, change the volume ratio of propane / oxygen in the feed gas, and the reaction result obtained is: when the volume ratio of propane / oxygen is 0.5%, the conversion of propane is 35.1%, and the selectivity of propionaldehyde is 4.3%; When the volume ratio of propane / oxygen was 1.0%, the conversion of propane was 30.5%, and the selectivity of propionaldehyde was 5.0%; when the volume ratio of propane / oxygen was 1.5%, the conversion of propane was 19.8%, and the selectivity of propionaldehyde was 19.8%. The selectivity was 5.9%.

Embodiment 3

[0021] Example 1 was repeated, when the volume ratio of propane / oxygen was 0.5%, the reaction result obtained under different discharge voltages was: when the discharge voltage was 15.0kV, the conversion of propane was 3.3%, and the selectivity of propionaldehyde was 2.1%; when the discharge voltage is 17.6kV, the propane conversion rate is 20.4%, and the selectivity of propionaldehyde is 3.5%; when the discharge voltage is 19.3kV, the propane conversion rate is 27.9%, and the selectivity of propionaldehyde is 4.0% .

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com