Fastener type steel pipe scaffold formwork support

A scaffolding and steel pipe technology, which is applied to formwork/formwork/work frame, on-site preparation of building components, construction, etc., can solve the critical load limitation of steel pipe scaffolding formwork support without fasteners, no series of erection structure dimensions, Material waste cost and other issues

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

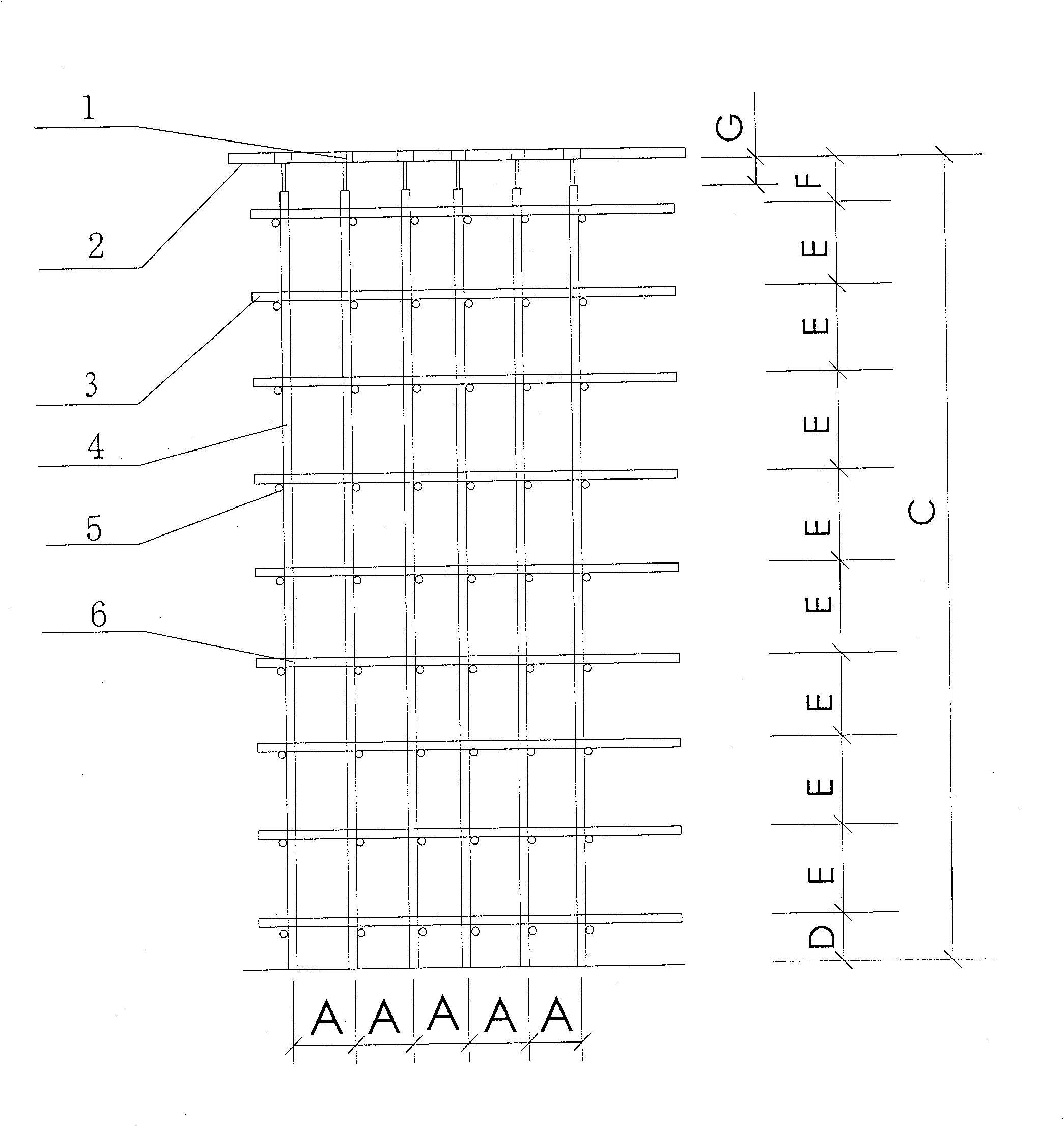

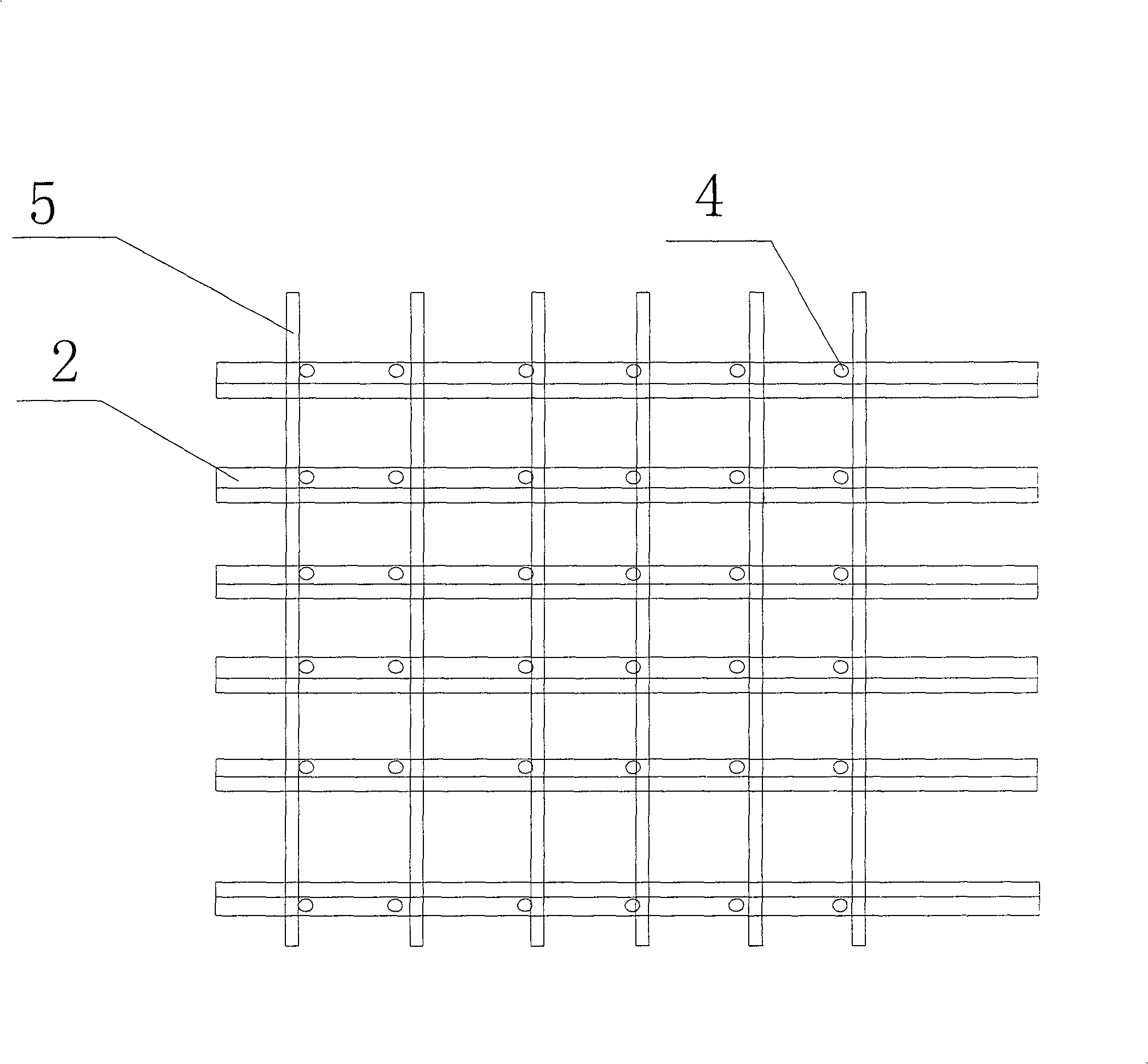

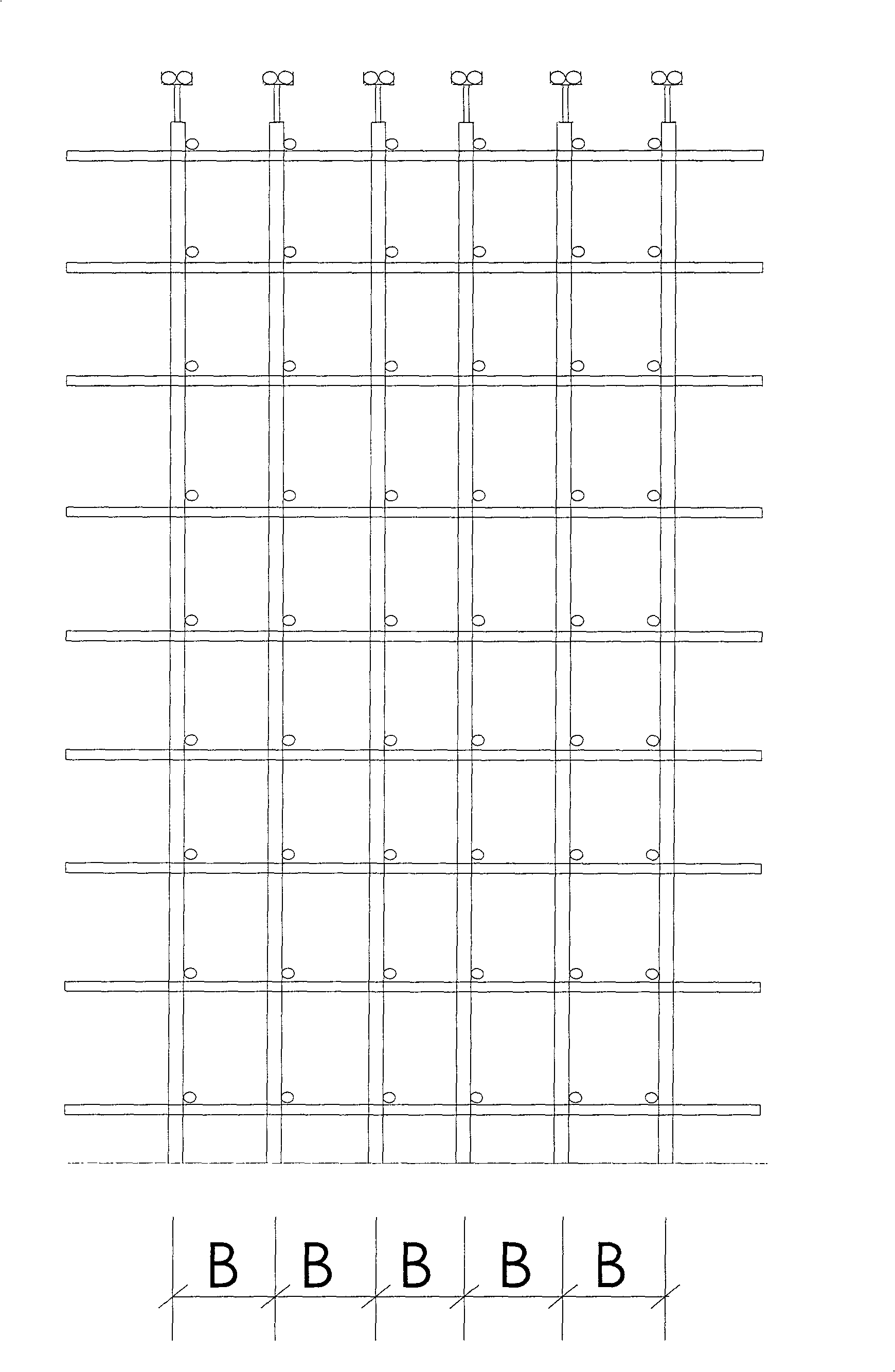

[0016] A fastener-type steel pipe scaffold formwork support, including a vertical steel pipe 4, a longitudinal horizontal rod 3 and a horizontal horizontal rod 5; the nodes are connected by malleable cast iron fasteners 6, and the upper part of the bracket is supported by an adjustable bracket 1 Φ48×3.5 double steel pipes 2 As the main beam of the support formwork, the bottom of the adjustable bracket 1 is inserted into the steel pipe 4 of the support vertical rod and fixed. The bracket has 5 spans in the vertical direction and 5 spans in the horizontal direction, loaded within the range of 5 spans × 5 spans, and there is no span increase outside the loading area; the height-to-width ratio of the bracket = 8.15÷(5×0.6) = 2.71; the sweeping rod is the lower cross bar of the bracket, D is the height of the sweeping rod.

[0017] The distance from the upper surface of the adjustable bracket to the bottom surface of the vertical steel pipe, that is, the height C is 8.15m, the dist...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com