Water electrolysis apparatus for producing hydrogen gas as auxiliary fuel for engine by low current

An auxiliary fuel and engine technology, applied in the electrolysis process, electrolysis components, etc., to achieve the effects of high energy conversion efficiency, low production cost, and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

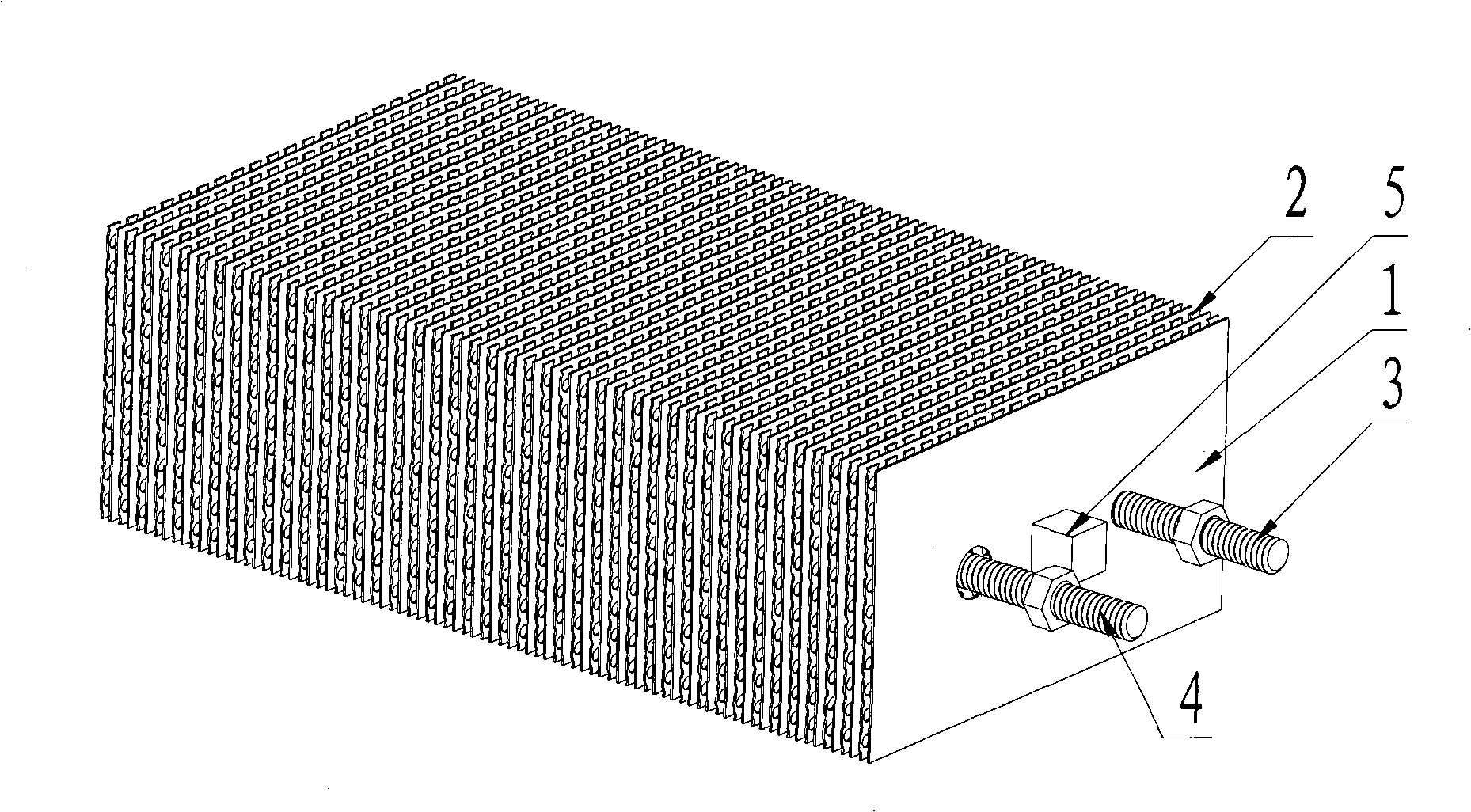

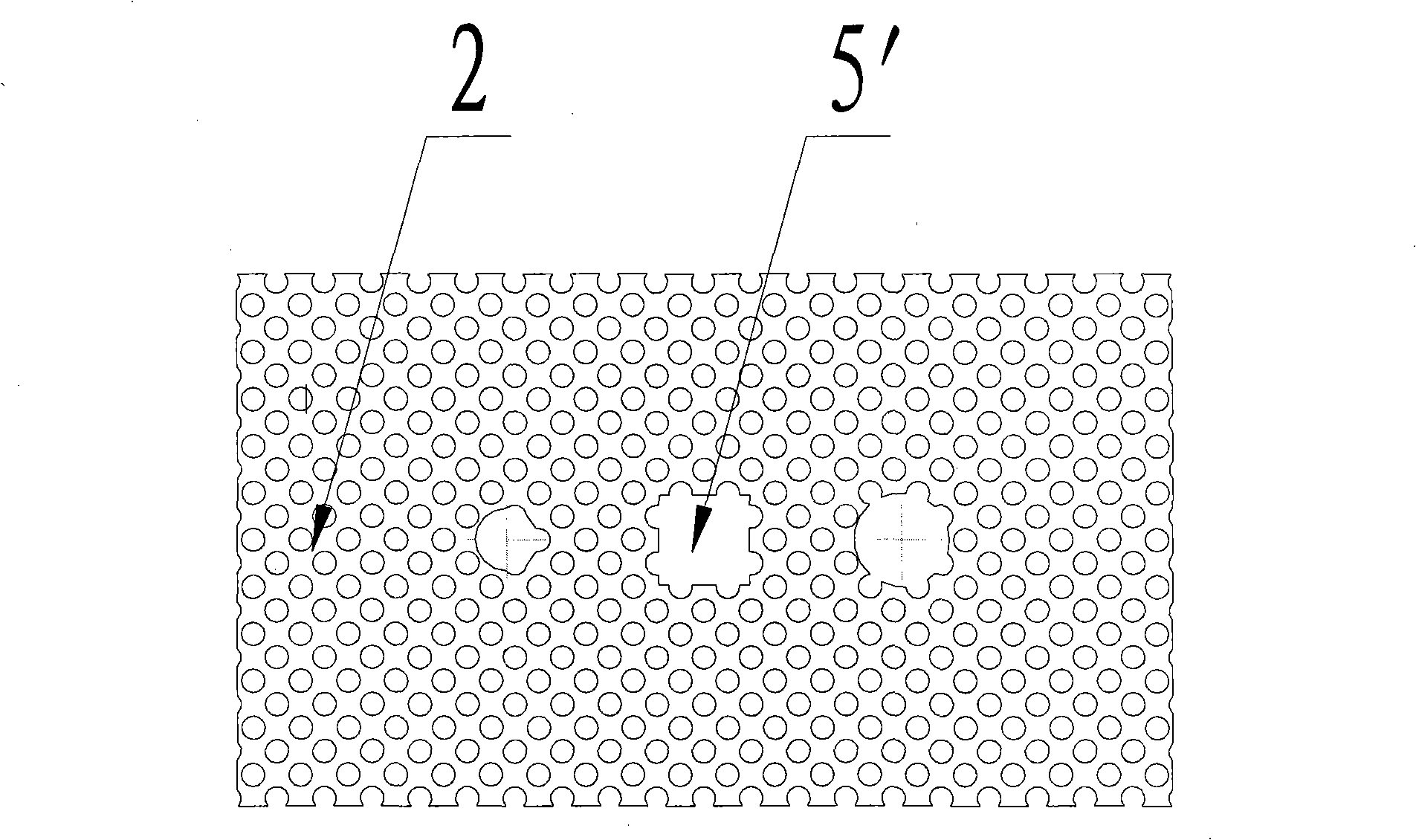

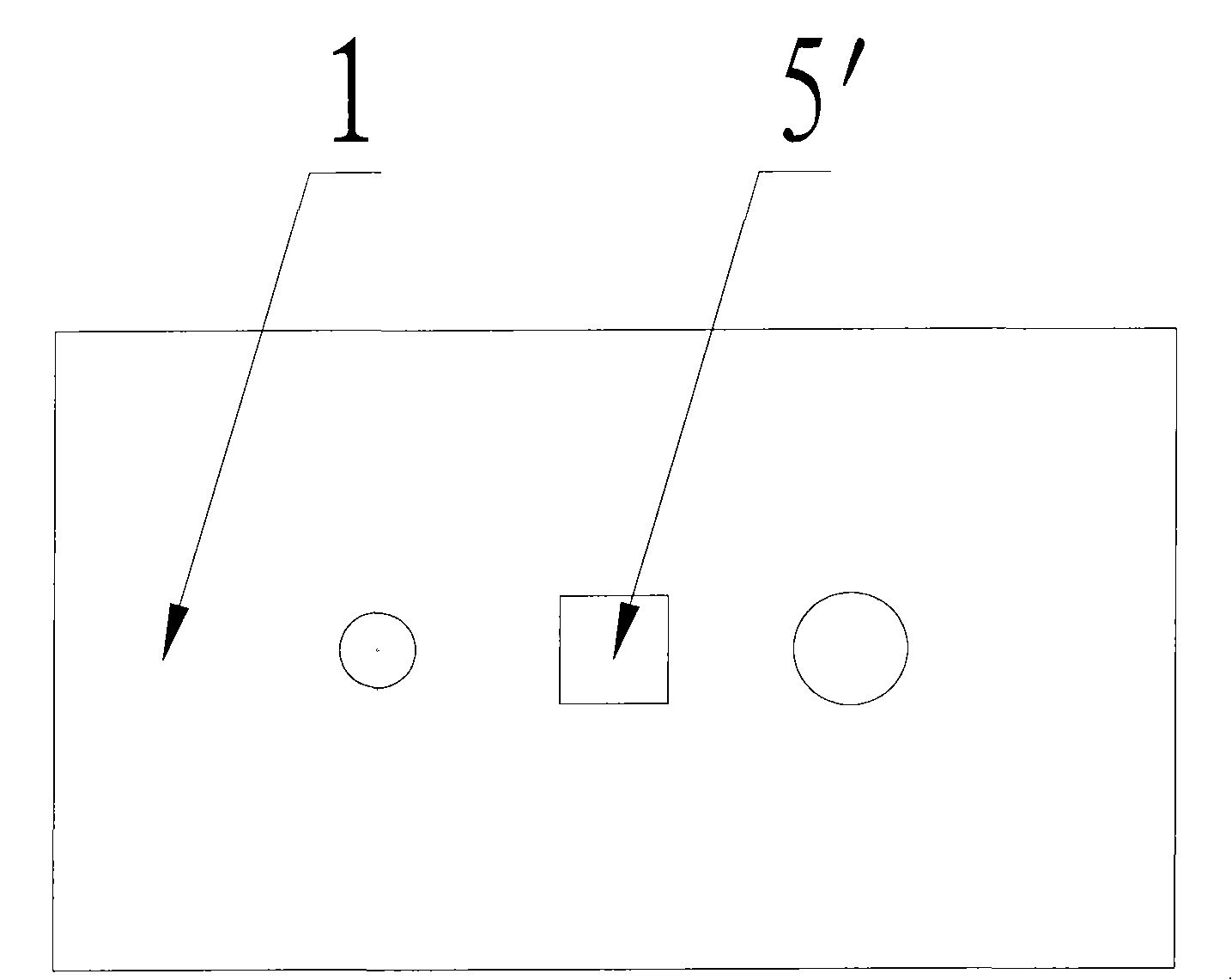

[0019] A water electrolysis device that generates hydrogen at low current for the engine as an auxiliary fuel, including a positive electrode plate 1, a negative electrode plate 2, a positive electrode rod 3, a negative electrode rod 4 and a glue rod 5, and a stainless steel conductor is passed between the positive electrode plates The negative electrode plates are also connected by stainless steel conductors, and the positive and negative electrode plates are separated by an insulator of high-temperature-resistant nylon material. The positive and negative electrode plates (1, 2) are alternately arranged and respectively connected by positive and negative electrode rods ( 3, 4) piercing, the positive and negative electrode rods (3, 4) are connected to the electrolysis power supply, the negative electrode plate 2 is a mesh structure, the positive electrode plate 1 is flat, and the positive electrode plate is 300 series Stainless steel, the negative electrode plate is 200 series ...

Embodiment 2

[0021] A water electrolysis device that generates hydrogen at low current for the engine as an auxiliary fuel, including a positive electrode plate 1, a negative electrode plate 2, a positive electrode rod 3, a negative electrode rod 4 and a glue rod 5, and a stainless steel conductor is passed between the positive electrode plates The negative electrode plates are also connected by stainless steel conductors, and the positive and negative electrode plates are separated by an insulator of high-temperature-resistant nylon material. The positive and negative electrode plates (1, 2) are alternately arranged and respectively connected by positive and negative electrode rods ( 3, 4) piercing, the positive and negative electrode rods (3, 4) are connected to the electrolysis power supply, the positive electrode plate 1 is a mesh structure, the negative electrode plate 2 is flat, and the negative electrode plate is 300 series Stainless steel, the positive electrode plate is 200 series ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| width | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com