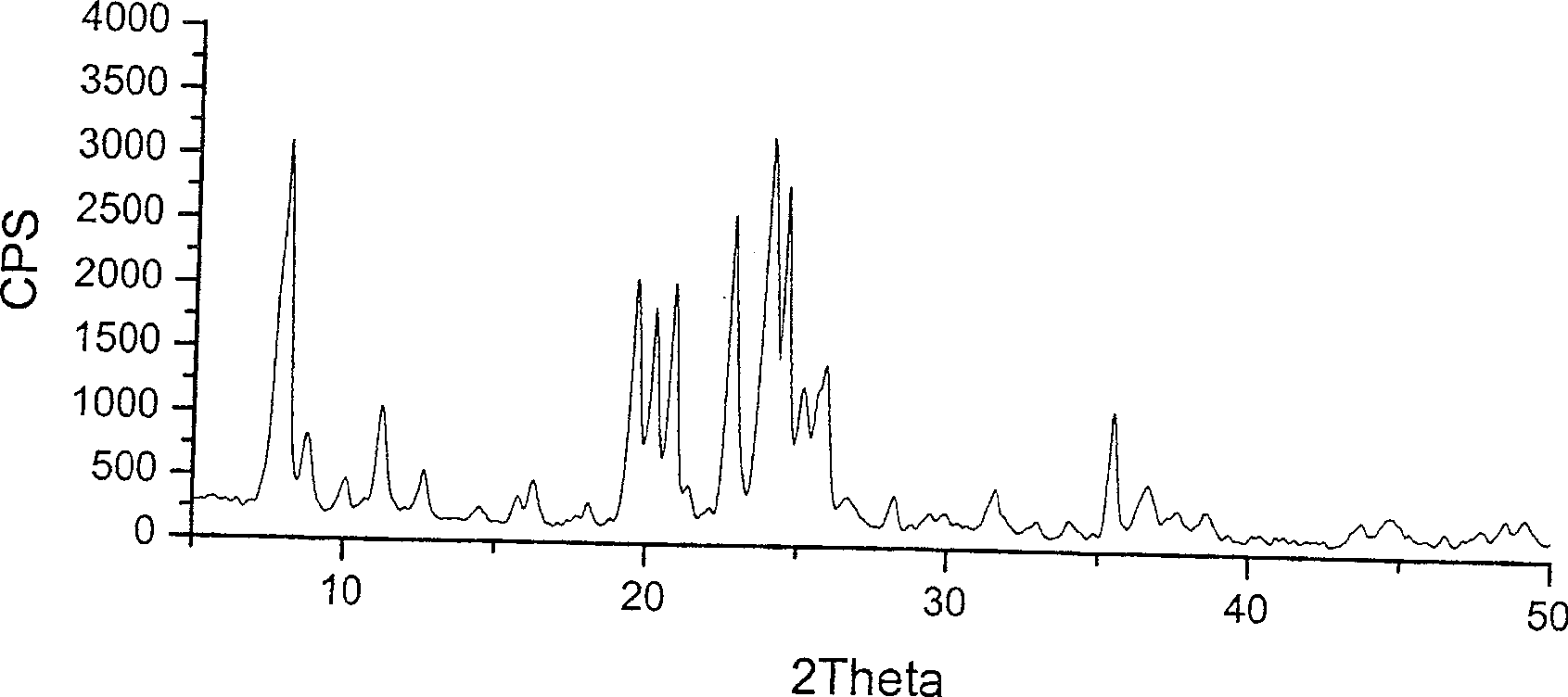

ZSM-22/ZSM-23 composite molecular sieve and preparation method

A composite molecular sieve, ZSM-23 technology, applied in the direction of crystalline aluminosilicate zeolite, etc., can solve the problems of not achieving the effect, and achieve the effect of low pour point, high yield and high viscosity index

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

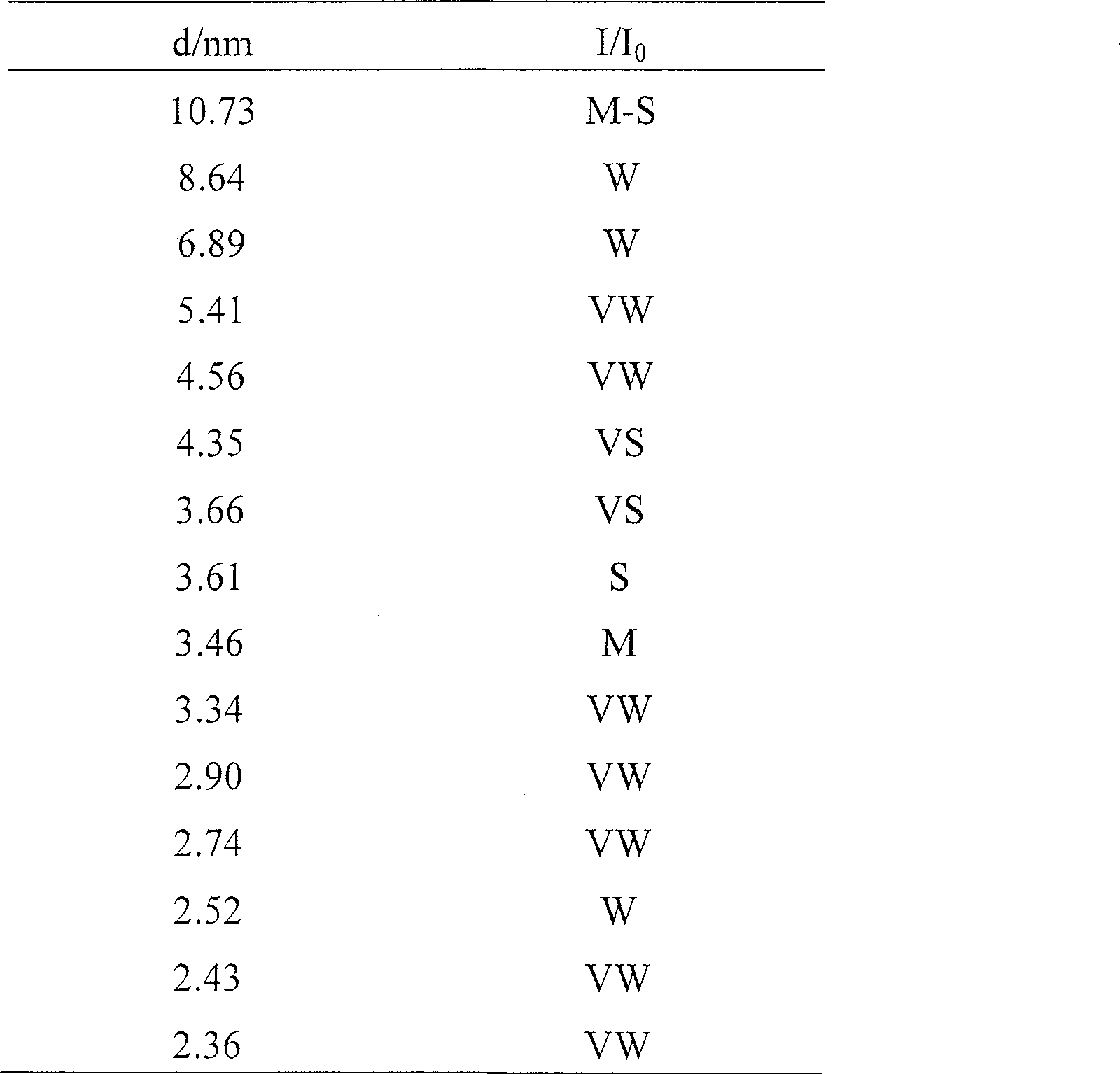

Embodiment 1

[0038] 4.4 g NaAlO 2 (Al 2 o 3 36.3%, Na 2 O 32.5%) was added in the mixture of 4.1 gram NaOH and 474 gram water, stirred 4 hours, then added the sodium type ZSM-22 molecular sieve synthesized by 15 gram comparative example, stirred 3 hours, added 66 gram pyrrolidine, stirred 1 hour , and finally add 261.1 grams of 30% silica sol to obtain the initial colloid. The molar composition of the initial colloid is: SiO 2 / Al 2 o 3 =83, R / SiO 2 =0.7,OH - / SiO 2 =0.08,H 2 O / SiO 2 =25, the addition of ZSM-22 molecular sieve is 0.2 of the silica weight. After stirring for 12 hours, it was transferred to a 1000 ml autoclave, and after sealing, the stirring speed was adjusted to 300 rpm, and the temperature was raised to 165° C. in 4 hours, followed by hydrothermal crystallization for 72 hours. After the crystallization was completed, the autoclave was placed in water for rapid cooling, the product was filtered and washed until the pH of the filtrate was neutral, and then drie...

Embodiment 2

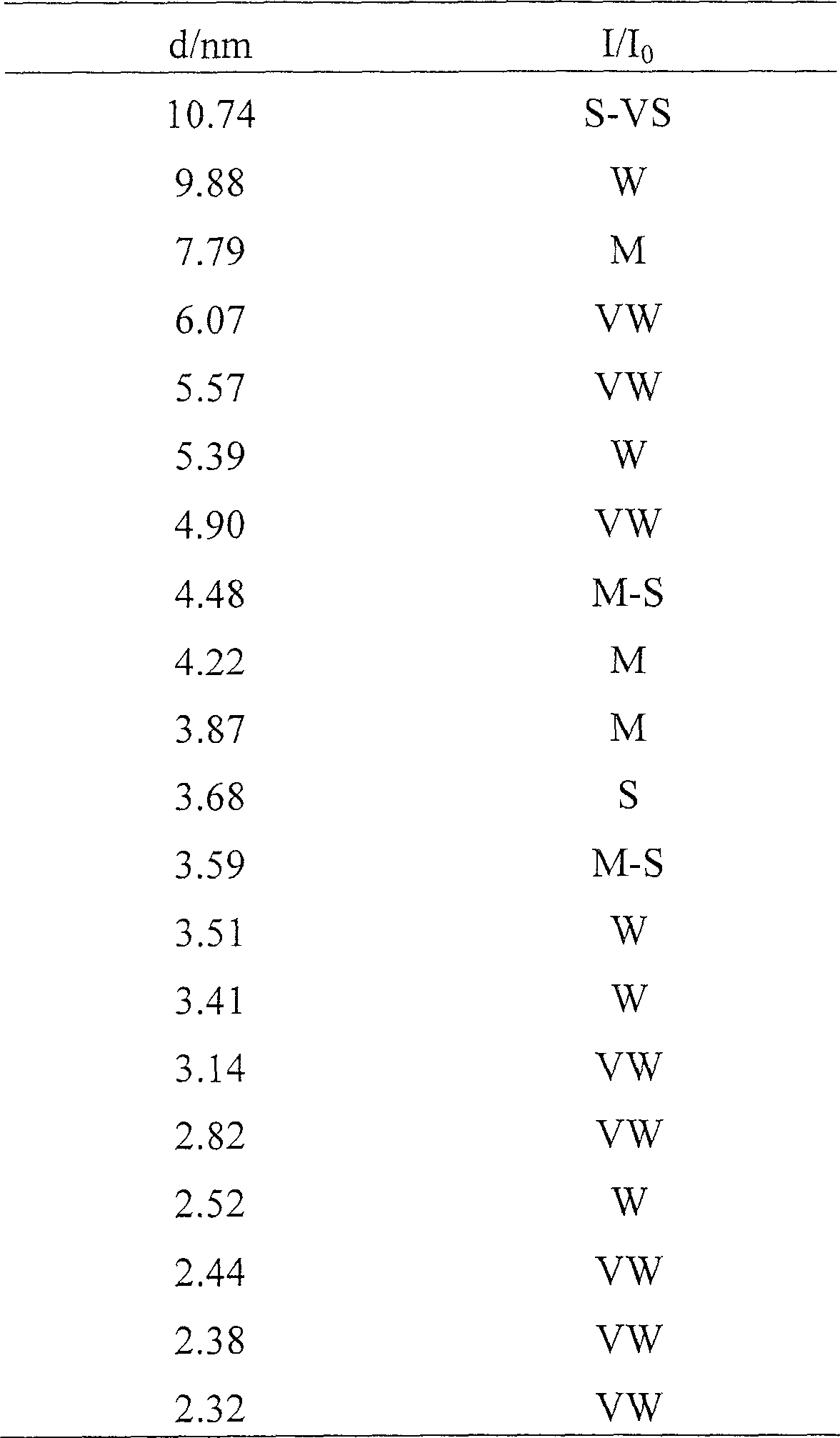

[0040] 6.1 g NaAlO 2 (Al 2 o 3 36.3%, Na 2 O 32.5%) was added in the mixture of 4.1 gram NaOH and 1232 gram water, stirred 4 hours, then added the hydrogen type ZSM-22 molecular sieve synthesized by 45 gram comparative example, stirred 3 hours, added 283 gram pyrrolidine, stirred 1 hour , and finally add 261.1 grams of 30% silica sol to obtain the initial colloid. The molar composition of the initial colloid is: SiO 2 / Al 2 o 3 =60, R / SiO 2 =3,OH - / SiO 2 =0.08,H 2 O / SiO 2 =65, the addition of ZSM-22 molecular sieve is 0.6 of the silica weight. After stirring for 12 hours, it was transferred to a 2000 ml high-pressure reactor. After sealing, the stirring speed was adjusted to 300 rpm, and the temperature was raised to 165° C. in 4 hours, and hydrothermal crystallization was carried out for 72 hours. After the crystallization was completed, the autoclave was placed in water for rapid cooling, the product was filtered and washed until the pH of the filtrate was neut...

Embodiment 3

[0042] 1.2 g NaAlO 2 (Al 2 o 3 36.3%, Na 2 O 32.5%) was added in the mixture of 25.6 gram NaOH and 474 gram water, stirred 4 hours, then added the sodium type ZSM-22 molecular sieve synthesized by 0.75 gram comparative example, stirred 3 hours, added 4.7 gram pyrrolidine, stirred 1 hour , and finally add 261.1 grams of 30% silica sol to obtain the initial colloid. The molar composition of the initial colloid is: SiO 2 / Al 2 o 3 =300, R / SiO 2 =0.05,OH - / SiO 2 =0.5,H 2 O / SiO 2 =25, the addition of ZSM-22 molecular sieve is 0.01 of the silica weight. After stirring for 12 hours, it was transferred to a 1000 ml autoclave, and after sealing, the stirring speed was adjusted to 300 rpm, and the temperature was raised to 165° C. in 4 hours, followed by hydrothermal crystallization for 72 hours. After the crystallization was completed, the autoclave was placed in water for rapid cooling, the product was filtered and washed until the pH of the filtrate was neutral, and the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com