Chemical amplification type positive resist composition

A technology of photoresist and composition, applied in optics, optomechanical equipment, instruments, etc., can solve the problems of magnetic film pattern size fluctuation, fluctuation, and inability to form fine magnetic film patterns, etc., and achieve good replicability effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0147] Examples of the present invention are described below, but the scope of the present invention is by no means limited by the examples provided below.

[0148] [Examples 1 to 4 (first form), Comparative Example 1]

[0149]

[0150] Five different positive photoresist compositions of Examples 1 to 4 and Comparative Example 1 were prepared in the following manner by changing the amount of component (A).

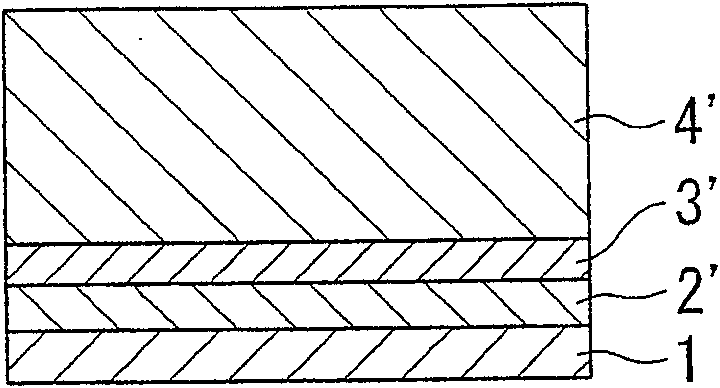

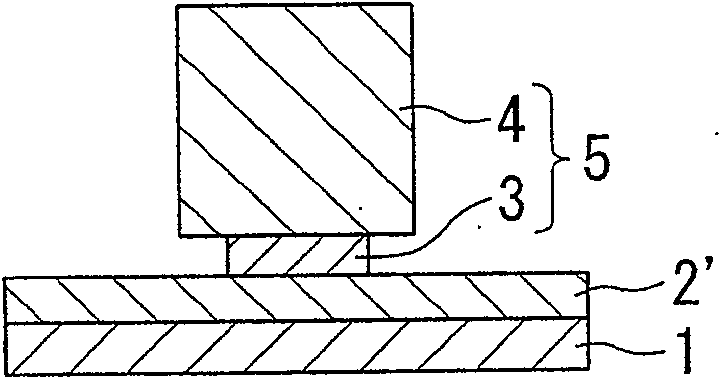

[0151] That is, in component (D), component (A), component (B), component (C), component (E) and any other components are uniformly dissolved to obtain a positive photoresist composition .

[0152] As component (A), anthracene methanol was used as shown in [Formula 1] below. In Examples 1 to 4, by using 4.0, 4.5, 5.0 and 5.5 parts by weight of component (A) per 100 parts by weight of component (B), the blending amount of component (A) was changed in a stepwise manner . In Comparative Example 1, component (A) was not added.

[0153] As component (B), 100 parts by wei...

Embodiment 5 to 12

[0178] [Embodiments 5 to 12 (second mode)]

[0179]

[0180] Eight different positive photoresist compositions of Examples 5 to 12 were prepared by changing the amount of component (A) in the following manner.

[0181] That is, in addition to changing the components in a stepwise manner by using 0.2, 0.5, 1.0, 1.5, 2.0, 3.0, 4.0 and 4.5 parts by weight of component (A) per 100 parts by weight of component (B), respectively ( The positive photoresist compositions of Examples 5 to 12 were prepared in the same manner as in Example 1 except for the mixing amount of A). The positive photoresist compositions of Examples 11 and 12 were the same as those of Examples 1 and 2 described above, respectively.

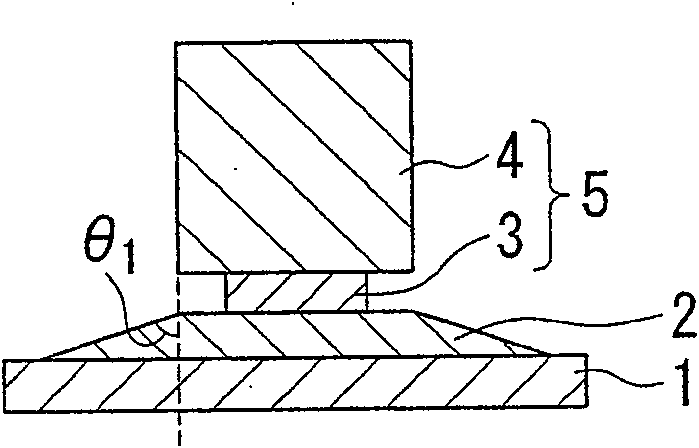

[0182] Then, each positive photoresist composition thus obtained was applied to the surface of a silicon wafer using a spin coater, and then prebaked and dried on a hot plate at 100° C. for 90 seconds, thereby forming a film having a film thickness of 800 nm. photoresist film. ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| angle | aaaaa | aaaaa |

| transmittivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com