Pump driving device in engine

A driving device and engine technology, which is applied in the direction of pressure lubrication of lubricating pumps, etc., can solve problems such as unsuitable driving, large mounting holes for driving pins, and difficulty in using driving pins, and achieve simplified structure, loosening prevention, and high torque transmission. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] The preferred embodiments of the present invention will be described below based on the drawings.

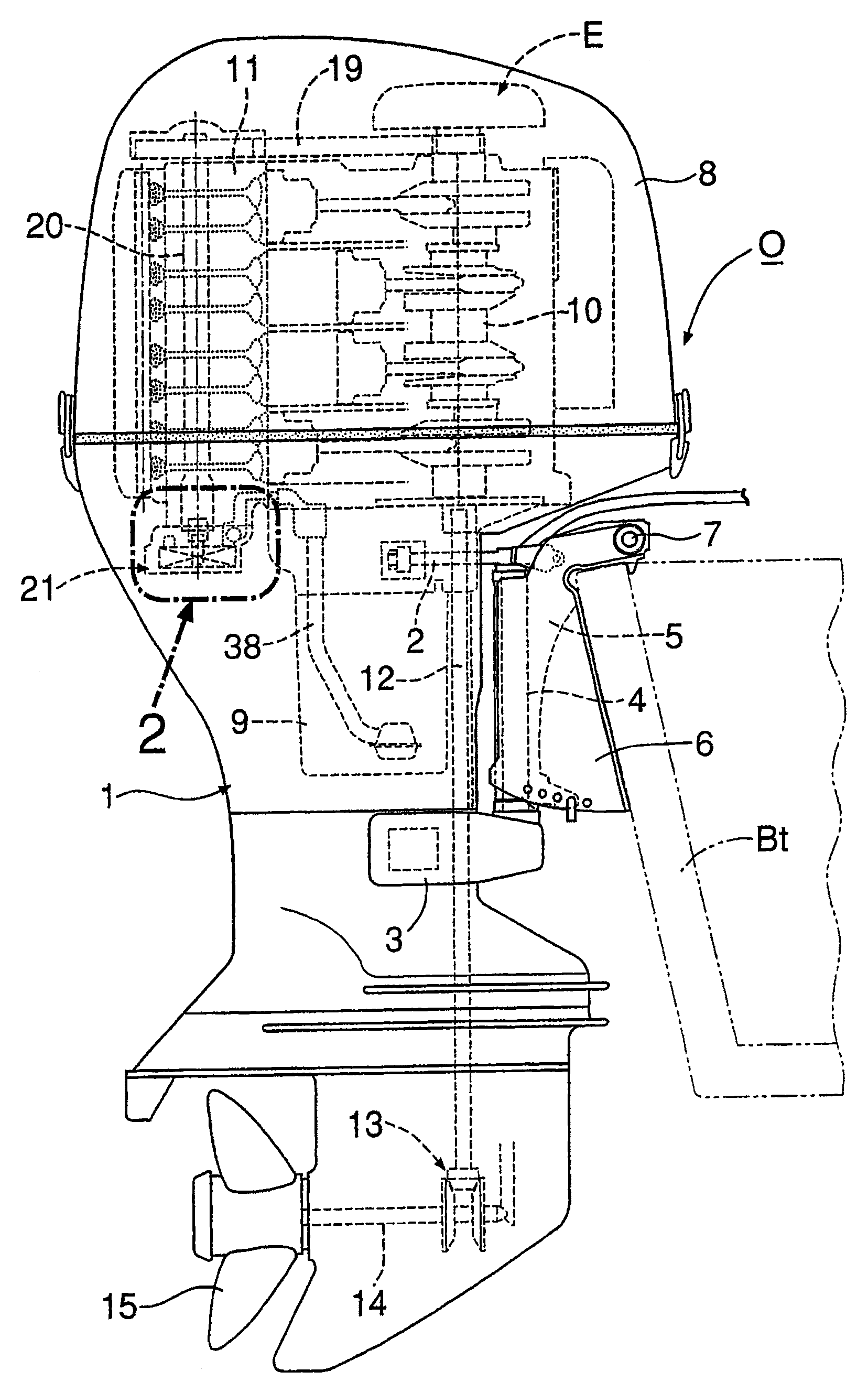

[0018] First of all, in figure 1 In the case 1 of the outboard motor O, a vertical rotating shaft 4 is arranged directly in front of the casing 1. The rotating shaft 4 is mounted on the casing 1 via the upper arm 2 and the rear arm 3, and the rotating shaft 4 is supported as The rotatable rotating shell 5 is connected to a tailstock 6 clamped on a transom Bt of the ship body via a horizontal inclined shaft 7. Therefore, the housing 1 can be turned left and right around the rotation axis 4 and can be tilted up and down around the tilt axis 7. A water-cooled 4-stroke engine E covered by a removable engine cover 8 is mounted on the upper part of the casing 1.

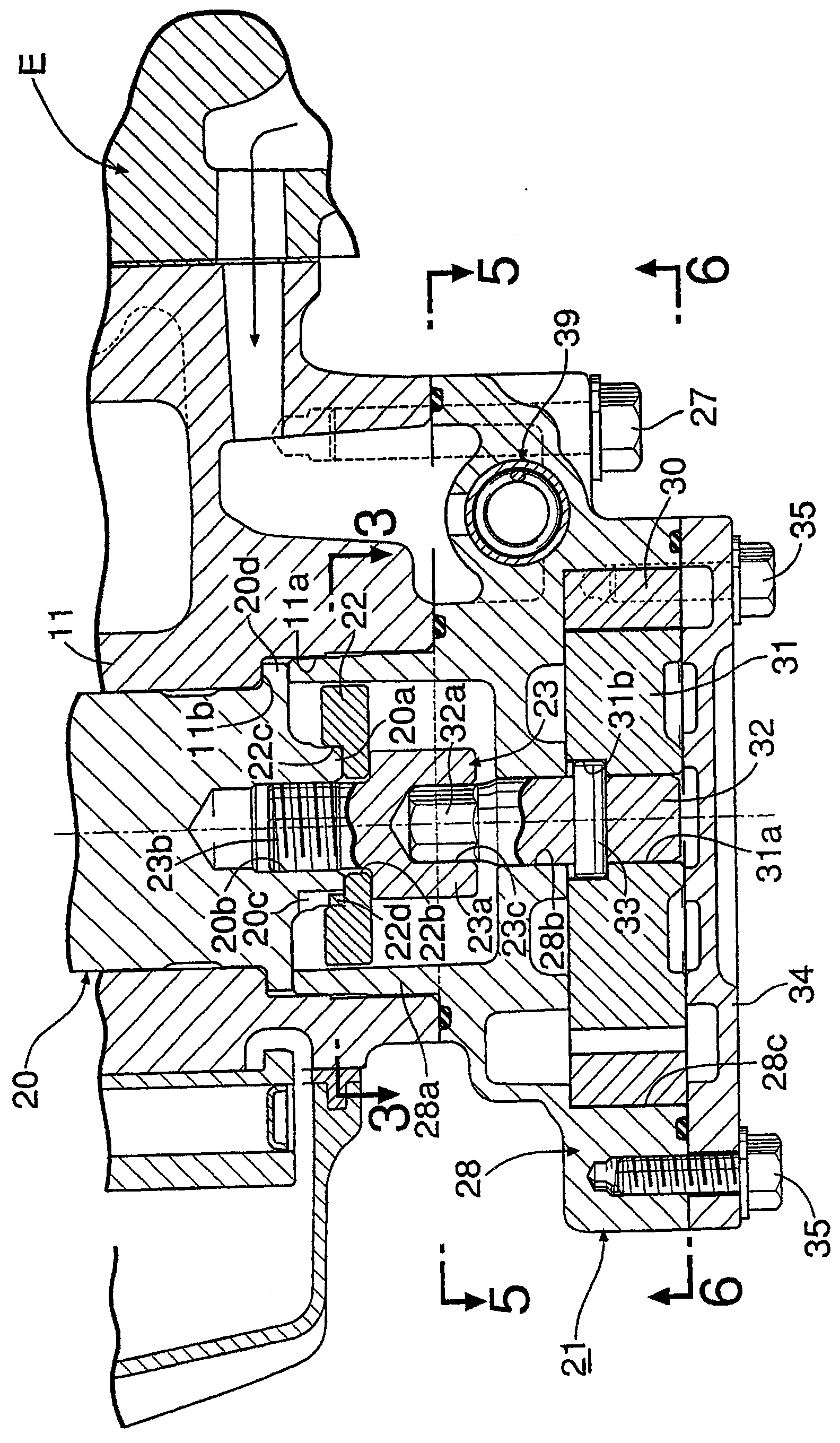

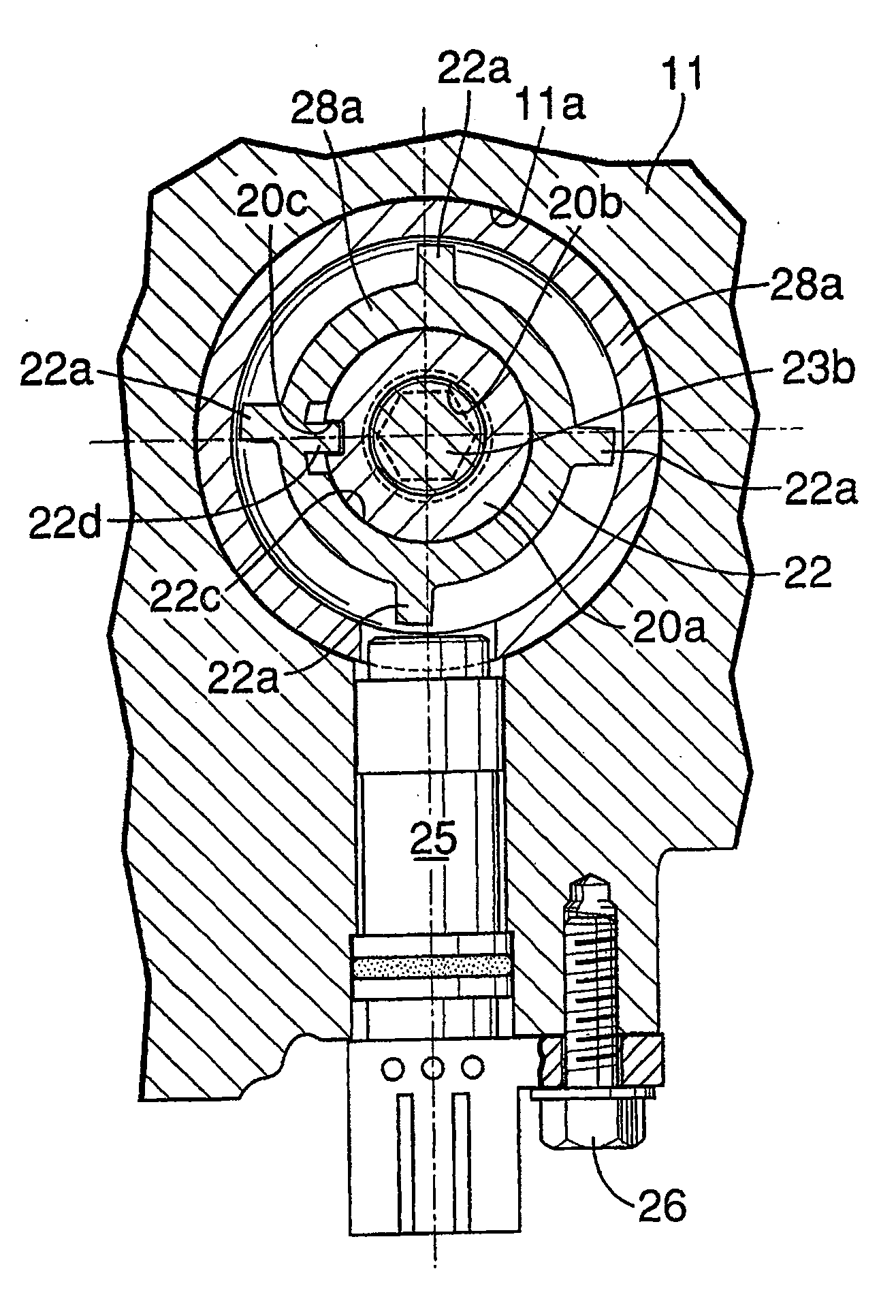

[0019] In this engine E, the crankshaft 10 placed in the longitudinal direction is close to the rotating shaft 4, and the cylinder head 11 is loaded toward the rear. In the housing 1 are arranged a longitudinally placed ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com