Improved tunnel smoke discharging method and tunnel fume discharging system with independent fume discharging device

A technology of smoke exhaust system and smoke exhaust device, which is applied in mine/tunnel ventilation, earthwork drilling, mining equipment, etc. It can solve problems such as waste, affecting the efficiency of smoke exhaust, and narrow cross-section, so as to improve effectiveness and economy Guaranteed safety and improved safety

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

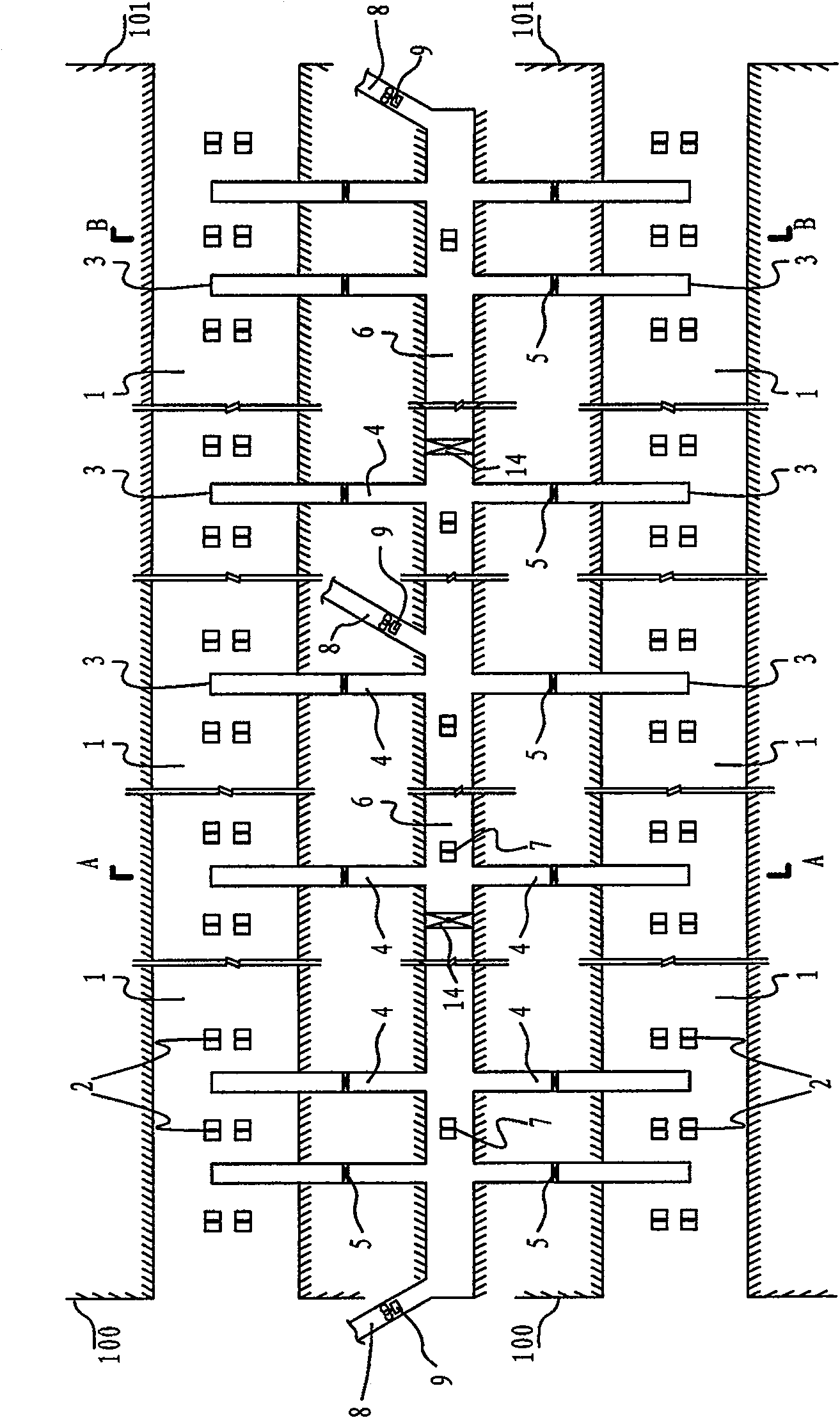

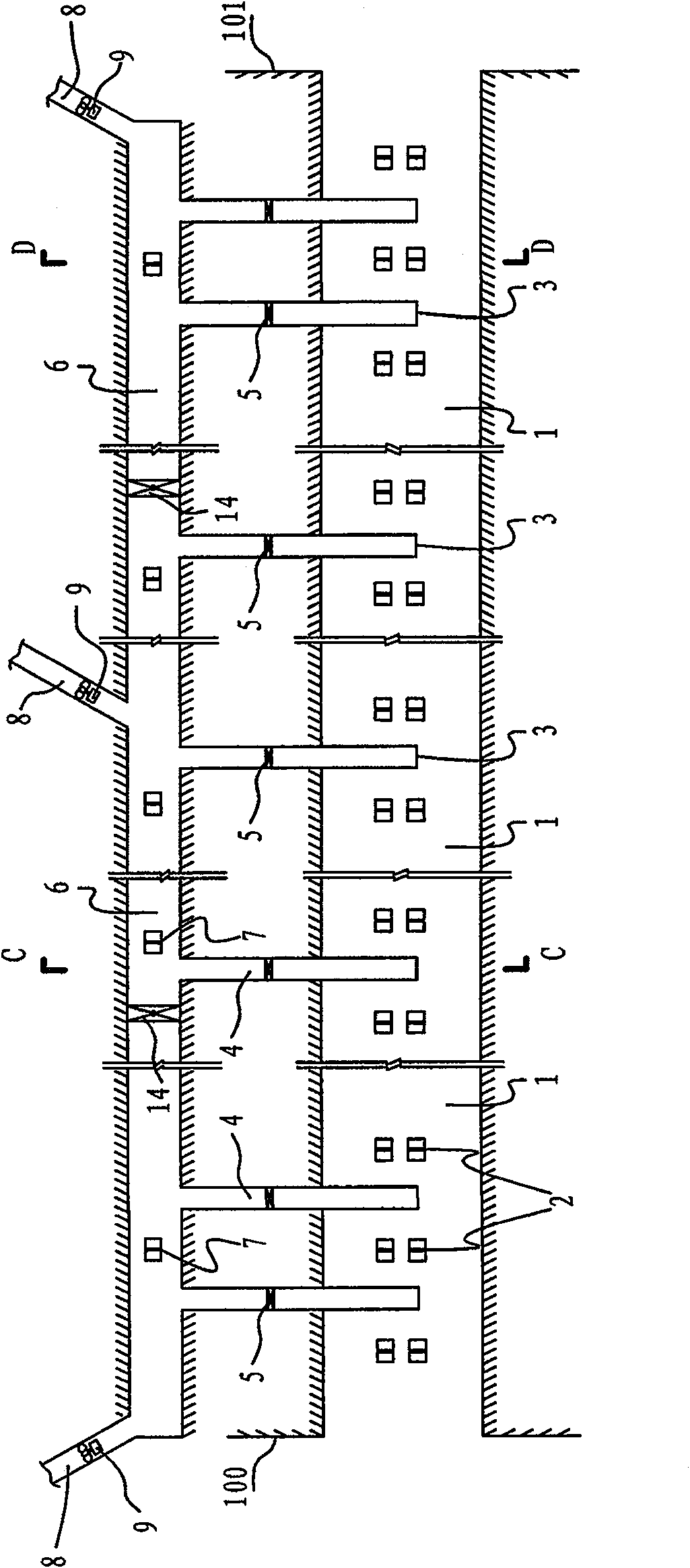

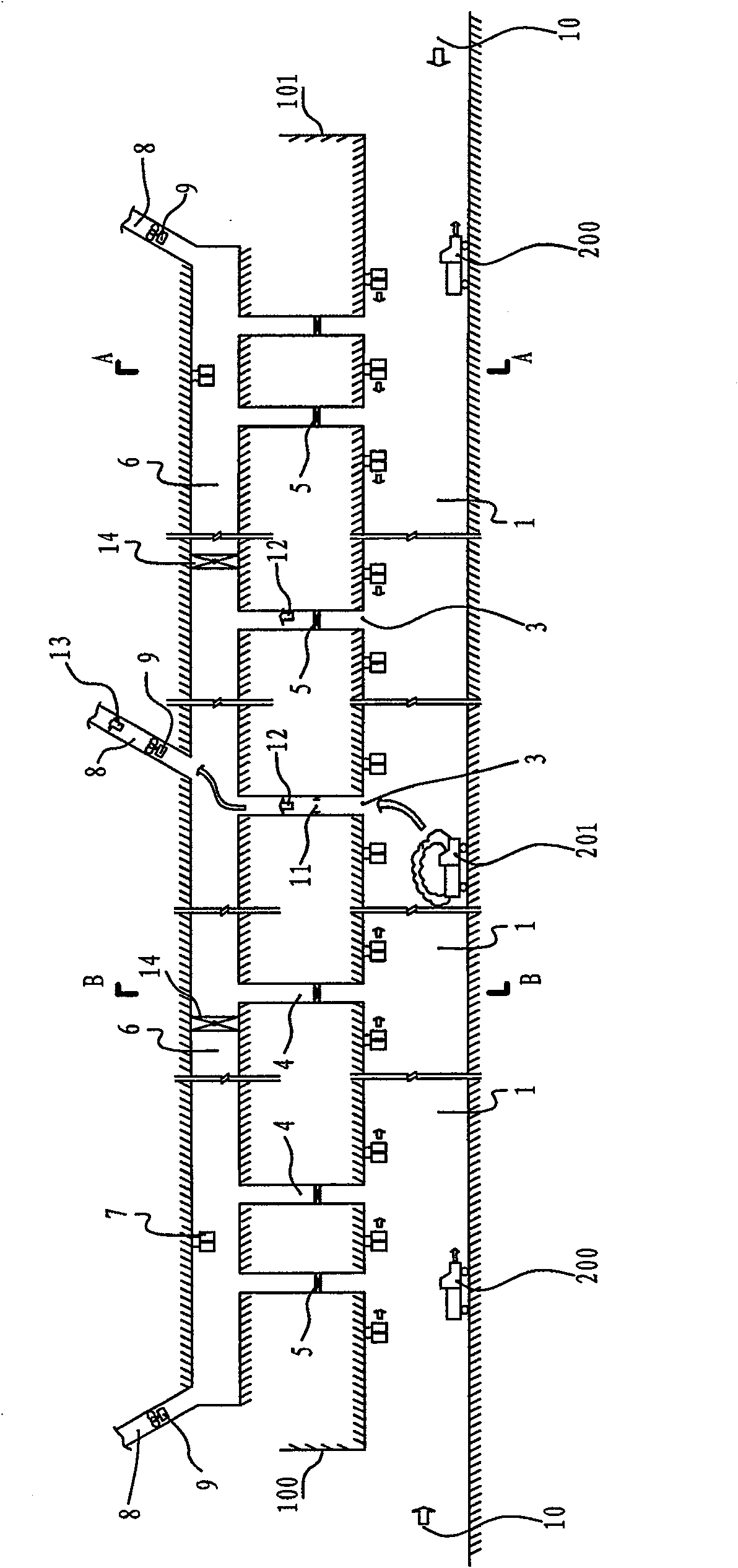

[0050] see figure 1 , 2 , the main tunnel has two ports, the tunnel entrance 100 and the tunnel exit 101. In practical applications, even if the tunnel has multiple ports, the smoke exhaust system is still applicable. The principles of ventilation and smoke exhaust are the same, but the specific arrangement of the equipment is different.

[0051] The whole main tunnel constitutes a tunnel main air duct (1), and several main air duct jet fans (2) are installed on the top, side or other positions of the tunnel as required in the tunnel. The independent smoke exhaust device includes a smoke exhaust duct (6), a smoke exhaust duct fan (7) and a smoke exhaust damper (14) provided as required, and a smoke exhaust port (3) arranged above the main air duct section of the tunnel , the smoke exhaust cross passage (4) connecting the tunnel smoke exhaust outlet (3) and the smoke exhaust air duct (6), the smoke exhaust damper (5) arranged in the smoke exhaust cross passage (4), and the smo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com