Air intake and exhaust pressure-bearing bidirectional pressure-regulating type water hammer protective device

A protective device and pressure regulating technology, applied in the direction of pipes/pipe joints/fittings, mechanical equipment, pipe components, etc., can solve the problems of water pollution and large installation height, and achieve the reduction of engineering cost, low installation height and low cost. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

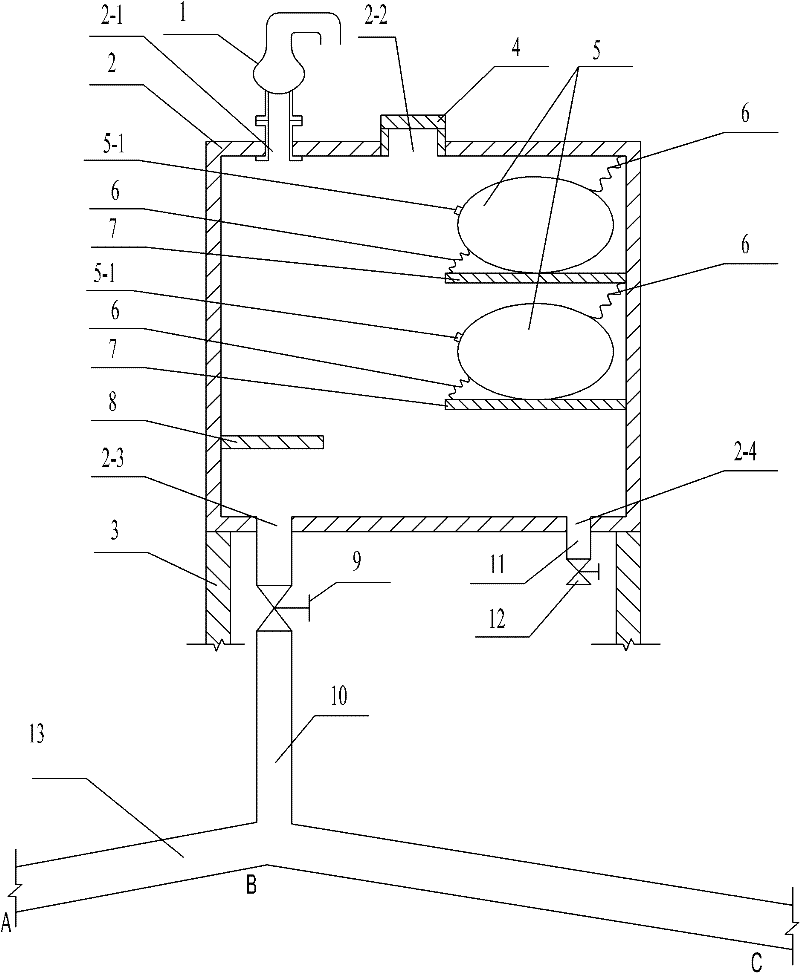

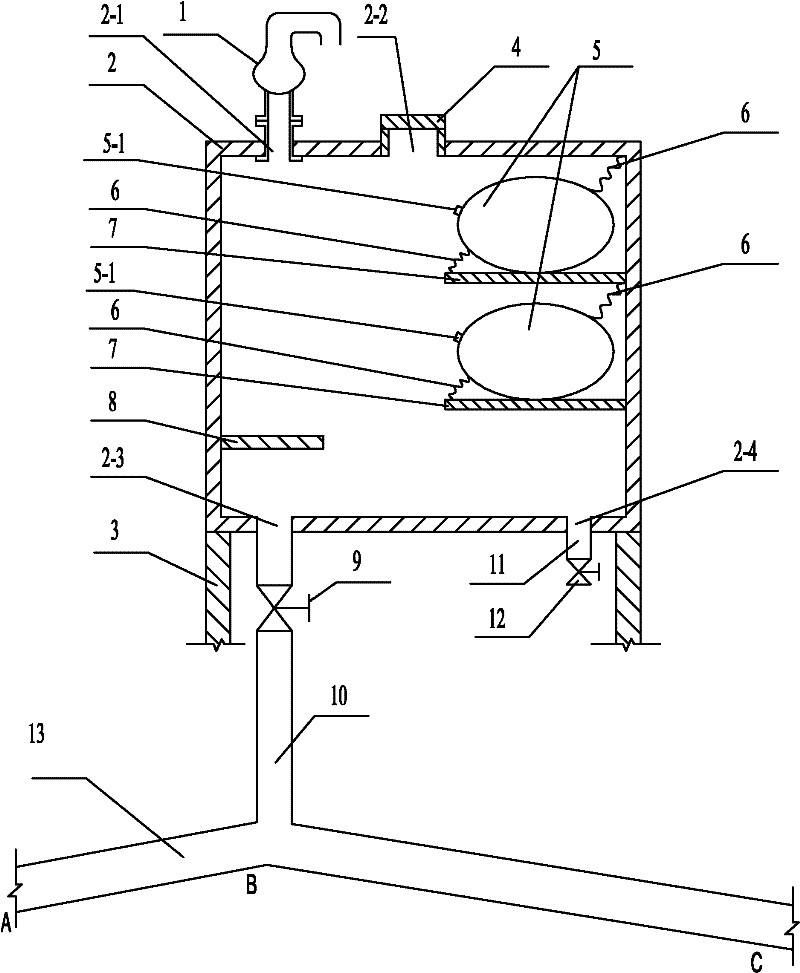

[0007] Specific implementation mode one: combine figure 1 This embodiment is described. The intake and exhaust pressure-bearing two-way pressure-regulating water hammer protection device of this embodiment includes an air valve 1, a pressure-bearing water tank 2, a support body 3, an inspection and repair airtight cover 4, an energy dissipation plate 8, an inspection valve 9, Water injection pipe 10, vent pipe 11, vent valve 12, a plurality of air bags 5, a plurality of elastic stay cords 6 and a plurality of air bag support plates 7; There are air valve port 2-1 and inspection port 2-2 on the top plate, air valve 1 is installed at air valve port 2-1, inspection airtight cover 4 is installed at inspection port 2-2, and the pressurized water tank 2 There are water injection port 2-3 and vent port 2-4 on the bottom plate of the water port, water injection pipe 10 is installed at the water injection port 2-3, inspection valve 9 is installed on the water injection pipe 10, and ven...

specific Embodiment approach 2

[0010] Specific implementation mode two: combination figure 1 The present embodiment will be described. The vent valve 12 of the present embodiment is a ball valve. So set, it has a large amount of drainage function. Other compositions and connections are the same as in the first embodiment.

specific Embodiment approach 3

[0011] Specific implementation mode three: combination figure 1 The present embodiment will be described, and the service valve 9 of the present embodiment is a butterfly valve. Other compositions and connections are the same as those in Embodiment 1 or Embodiment 2.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com