Locating and adhering mechanism of carton tissue of Tiandigai carton forming machine

A technology of forming machine, sky and earth cover, applied in the direction of carton/carton manufacturing machinery, paper/cardboard containers, containers, etc., can solve the problems of low work efficiency, inability to adapt to modern production, labor waste, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

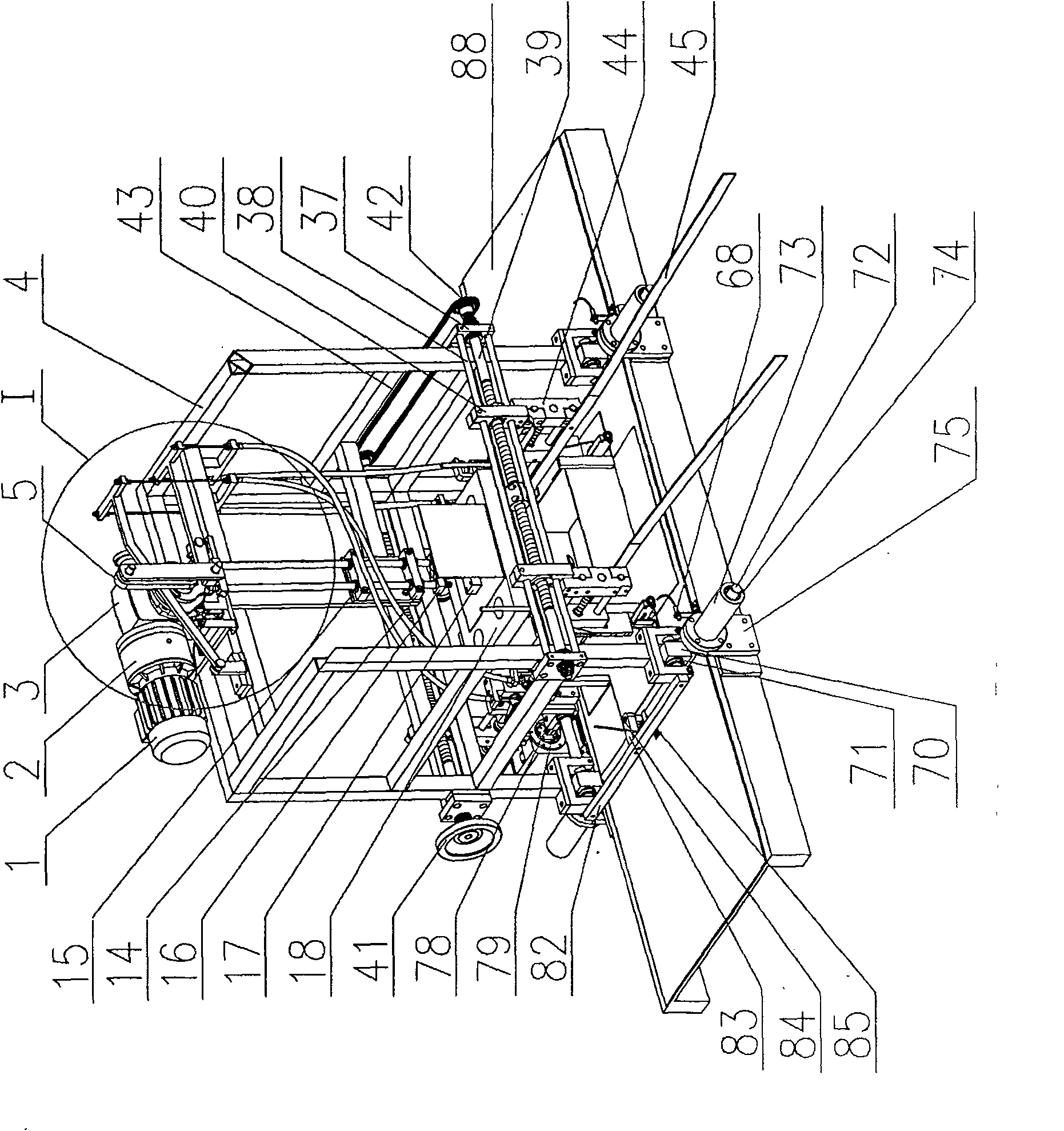

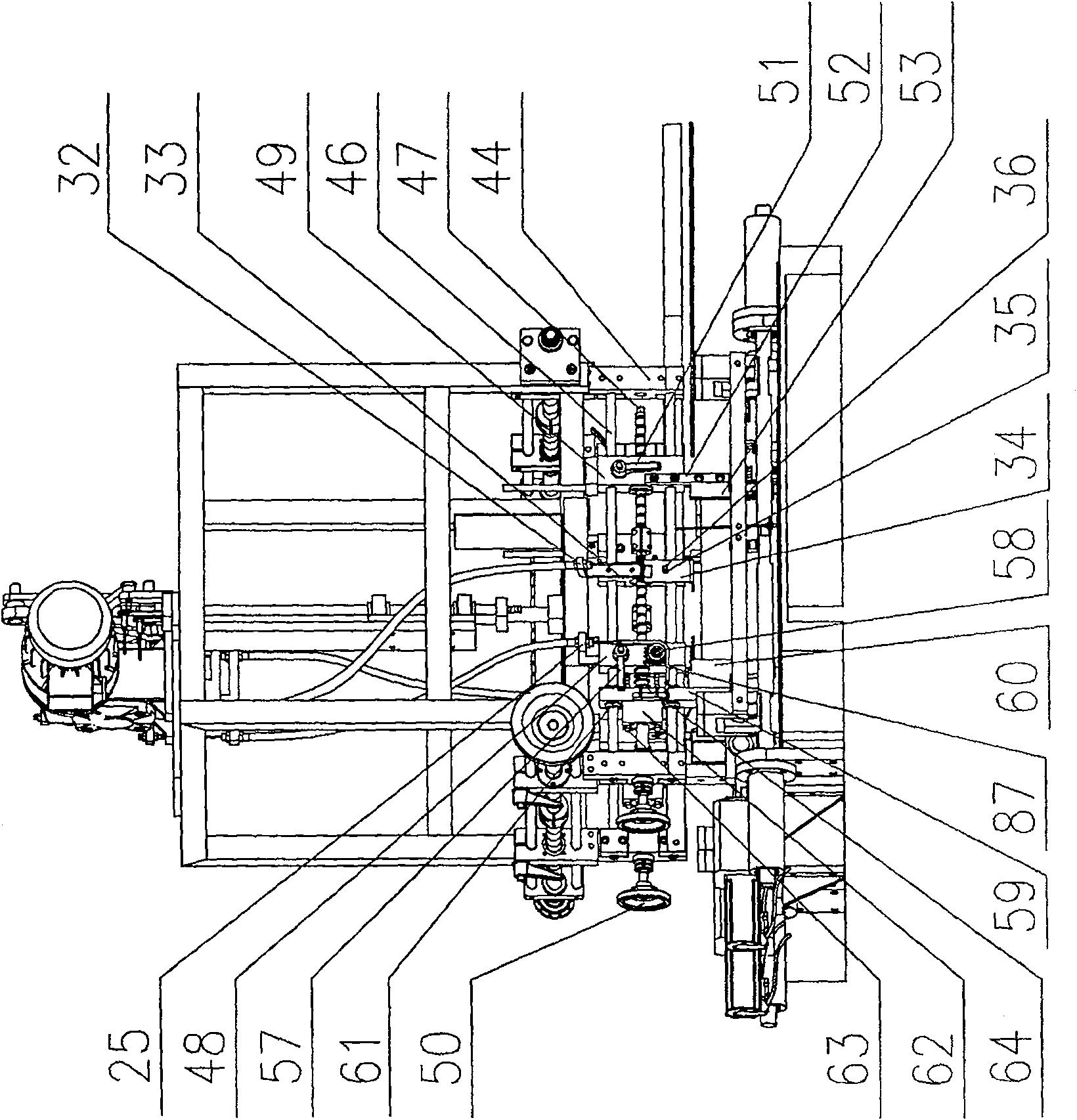

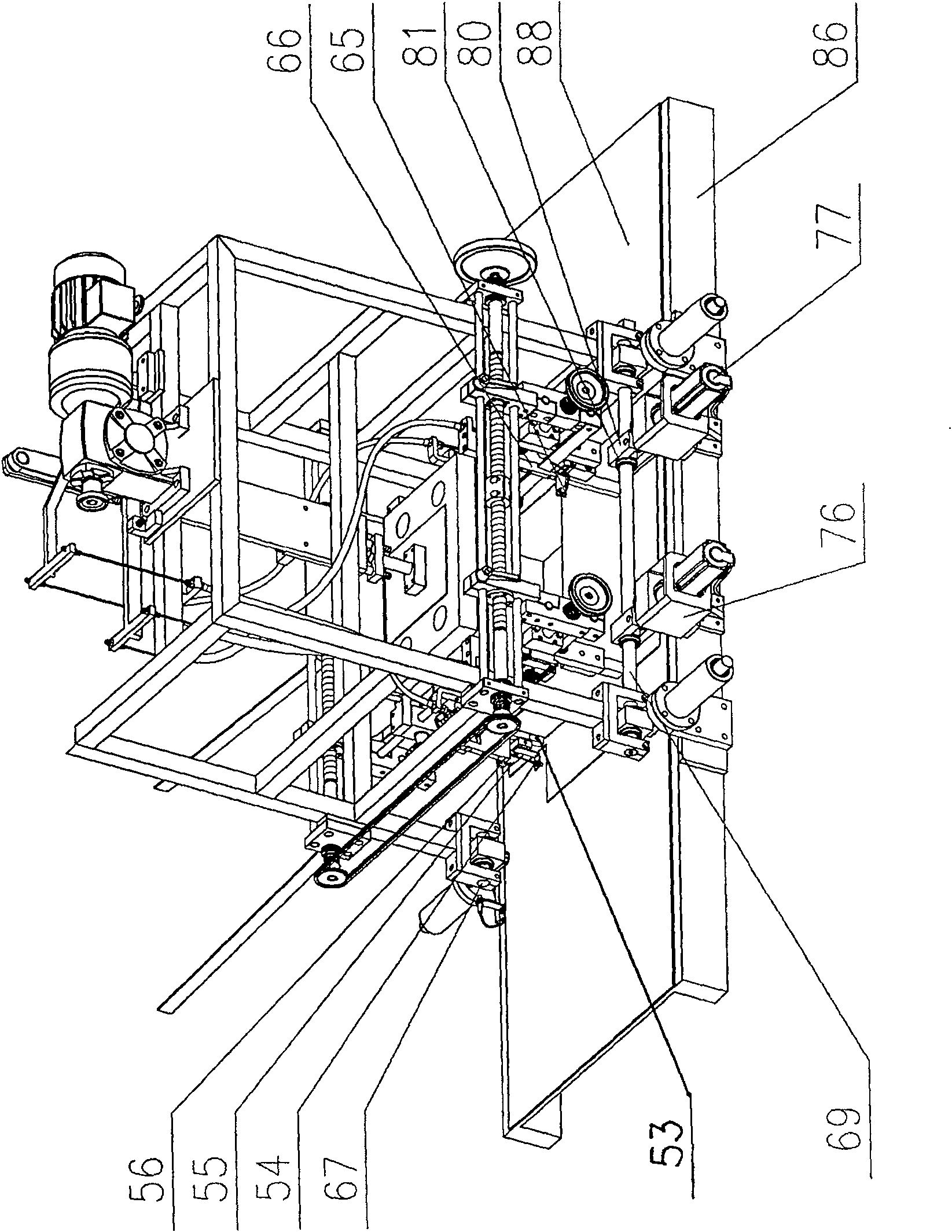

[0016] refer to figure 1 It can be seen that the blank box surface paper positioning and bonding mechanism of the heaven and earth cover carton forming machine of the present invention includes a frame 4, and the frame 4 is equipped with a lower box power drive device, a box mold lifting control device, and a blank box length. Adjustment device, blank box width adjustment and positioning device, rack installation device; among them:

[0017] [A] Reference figure 1 , the lower box power drive device is arranged on the top of the frame 4, and is composed of the lower box motor 1, the lower box electromagnetic clutch 2, and the worm gear reducer 3 in sequence;

[0018] [B] Reference figure 1 , Figure 4 , the box mold lifting control device is located in the middle of the frame 4, the worm gear reducer is equipped with a worm gear reducer swing rod 5 at the outer end of the output shaft of the worm gear reducer 3, and the other end of the worm gear reducer swing rod 5 passes t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com