Encircling type busbar arrangement method for vertical row cell

A busbar configuration and surround-type technology, which is applied in the field of aluminum electrolytic cell busbar current configuration, can solve problems such as excessive local magnetic field of the electrolytic cell, damage to cell stability, and hazards in production operation, so as to meet stability requirements, good design and production Demand, the effect of solving the magnetic field problem

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

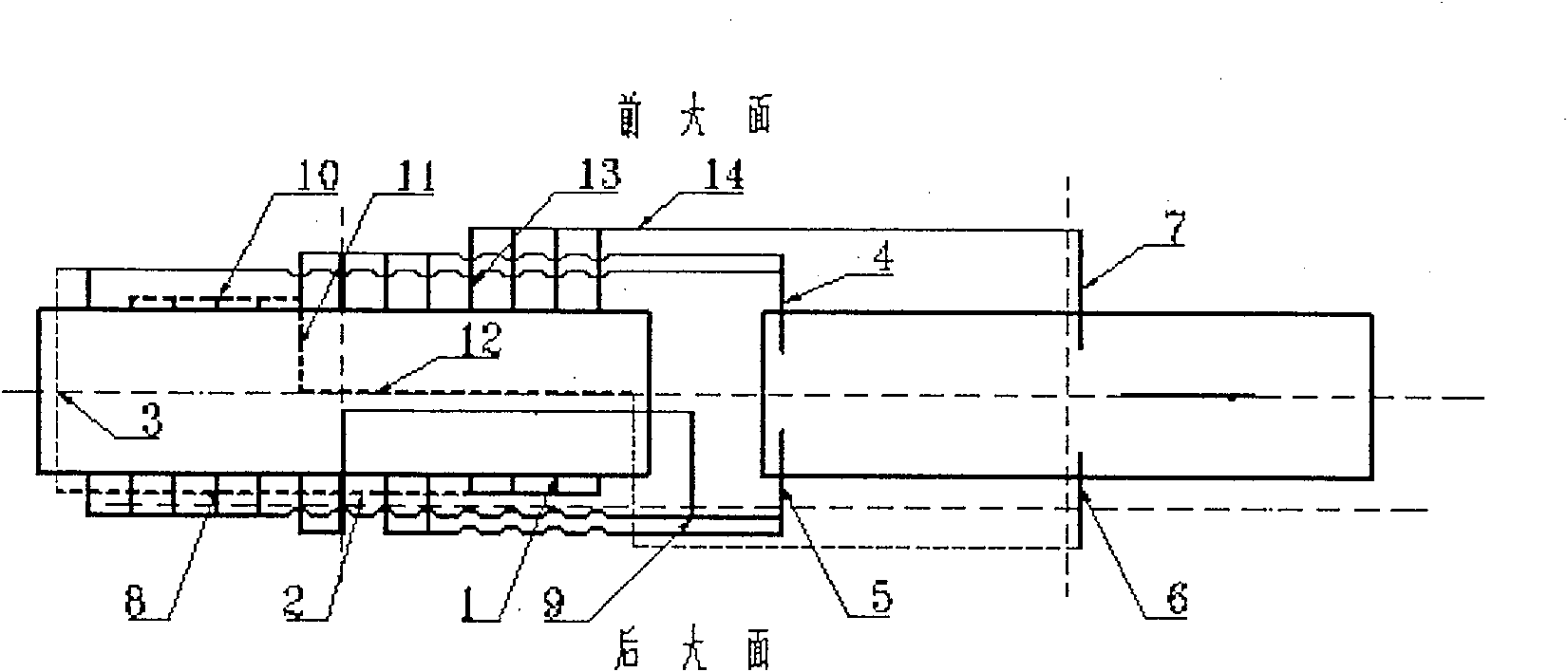

[0009] Embodiment of the present invention: the 15% current of the rear large surface in the electrolytic cell flows out through 4 cathode soft busbars (1), flows into the bottom busbar (3) after passing through the cathode busbars (2), and then flows into the front large surface cathode busbar. Downstream trough column busbar (4), the rest of the current flows out through 9 cathode soft busbars (8), and respectively enters the rear large surface column busbars (5) and (6) of the downstream trough through the cathode busbars (9); the front large surface 15% current , flows out through 4 cathode busbars (10), flows into the tank bottom busbar (12) after passing through the cathode busbar (11), and then flows into the rear large-face cathode busbar into the downstream tank column busbar (6), and the rest of the current passes through 9 cathode busbars (13) flows out, and enters respectively through the cathode busbar (14) the large-face column busbar (4), (7) before the downstrea...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com