Device and method for sticking substrate

A technology for manufacturing devices and manufacturing methods, which is applied in the field of liquid crystal display devices, and can solve the problems of lower yield, light leakage in light-shielding parts, uneven display, etc., and achieve the effect of easy maintenance and reduced configuration area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] (first embodiment)

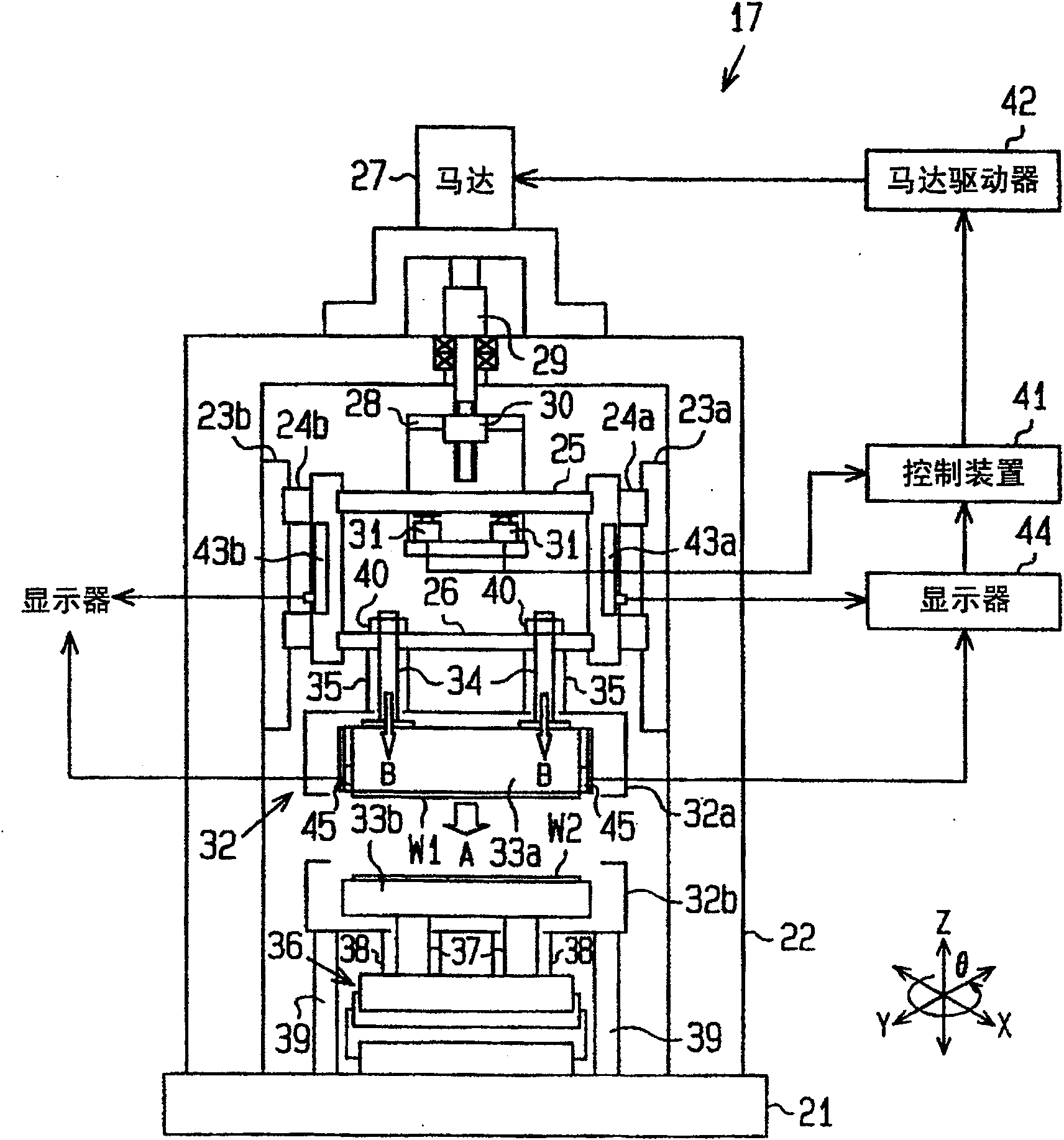

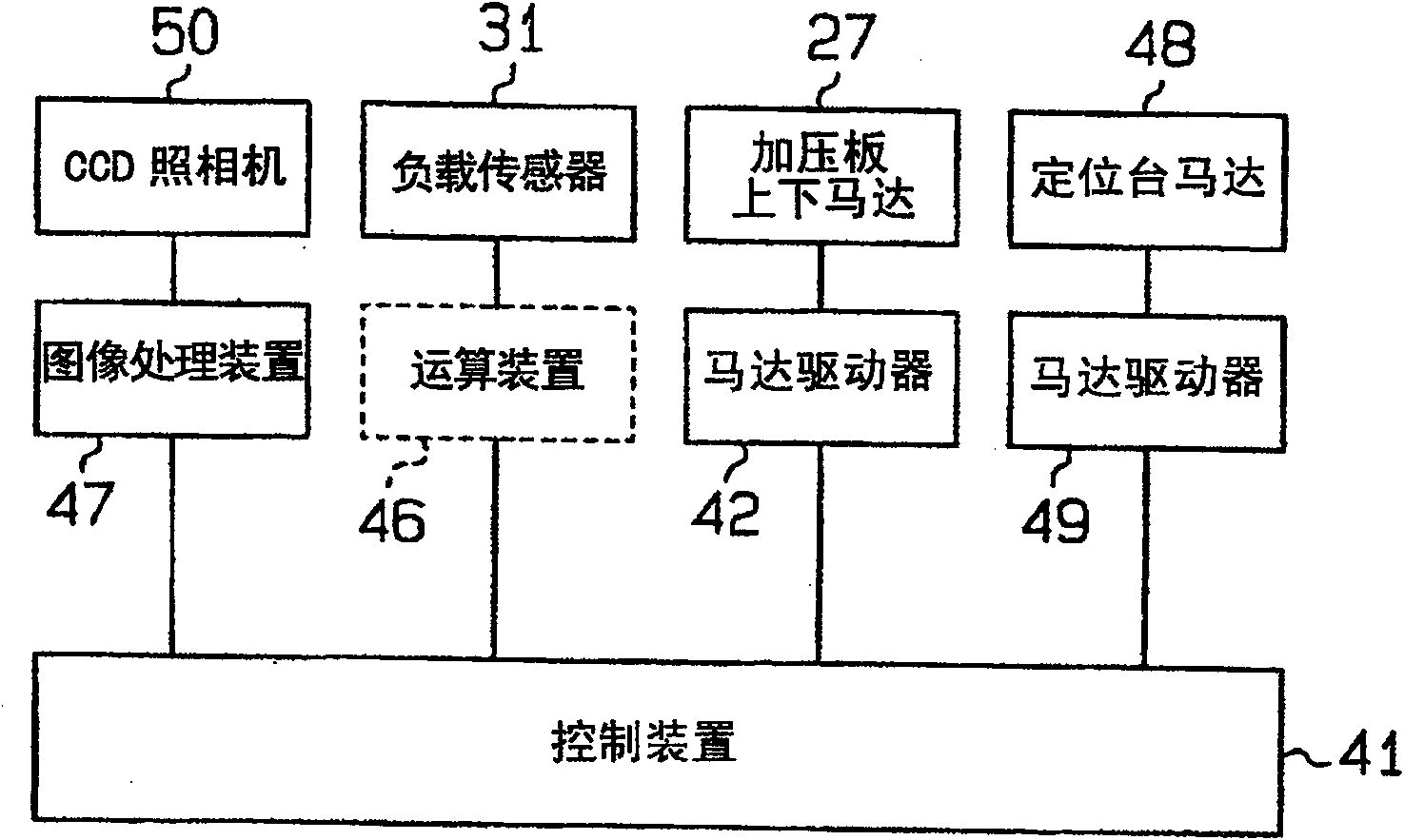

[0029] Below, refer to Figure 1 to Figure 4 , the first embodiment of the present invention will be described.

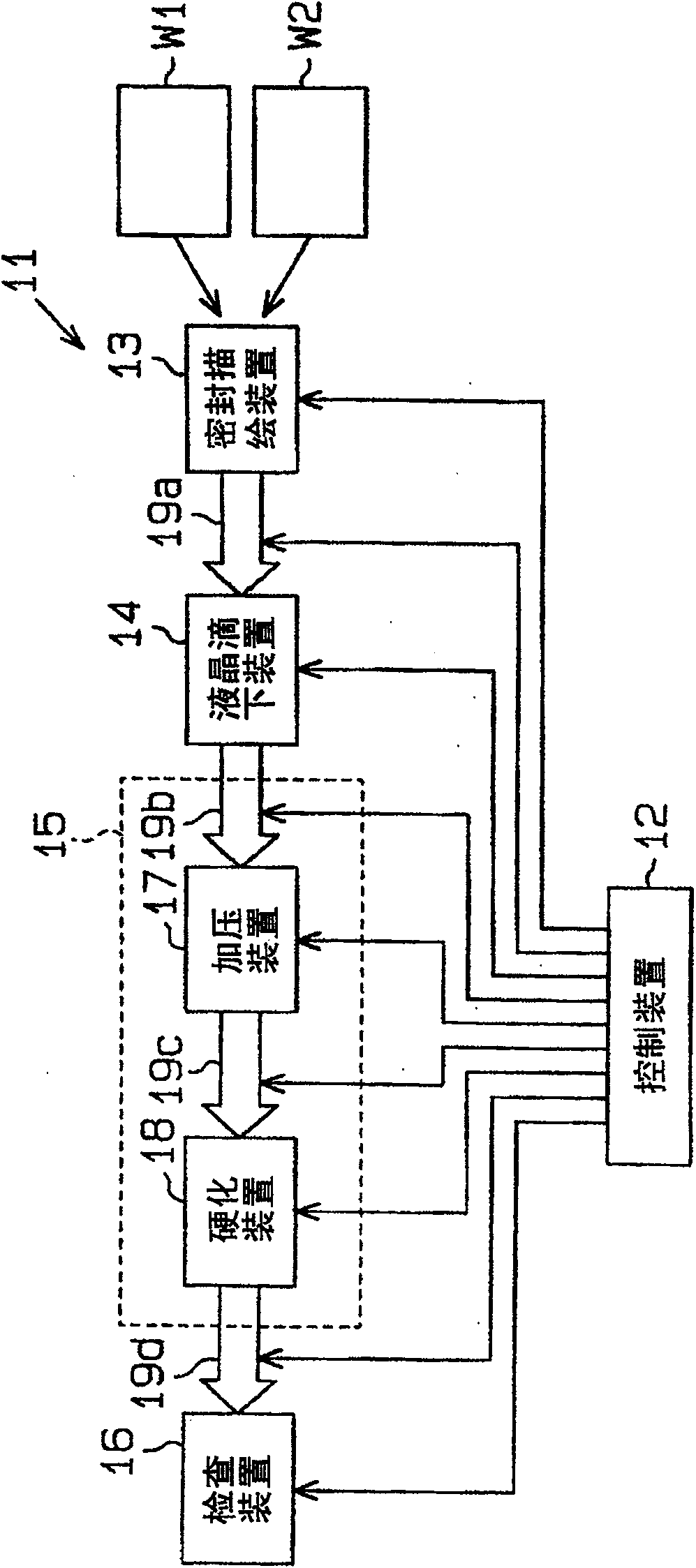

[0030] figure 1 This is a schematic structural diagram of a bonded substrate manufacturing apparatus that implements the steps of injecting and bonding liquid crystal in the liquid crystal cell process in the manufacturing process of a liquid crystal display device.

[0031] The bonded substrate manufacturing apparatus 11 seals liquid crystal between the supplied two types of substrates W1 and W2 to manufacture a liquid crystal display substrate. The liquid crystal display panel manufactured in this embodiment is, for example, an active matrix type liquid crystal display panel. The first substrate W1 is a color filter substrate (CF substrate) on which a color filter and a light-shielding film are formed, and the second substrate W2 is a color filter substrate (CF substrate) on which a color filter is formed. Array substrates (TFT subs...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com