Circuit board and manufacturing method thereof

A technology of circuit boards and substrates, which is applied in the manufacture of printed circuits, circuits, printed circuits, etc., can solve problems such as inability to observe, and achieve the effects of improving productivity, improving efficiency, and suppressing whitening

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

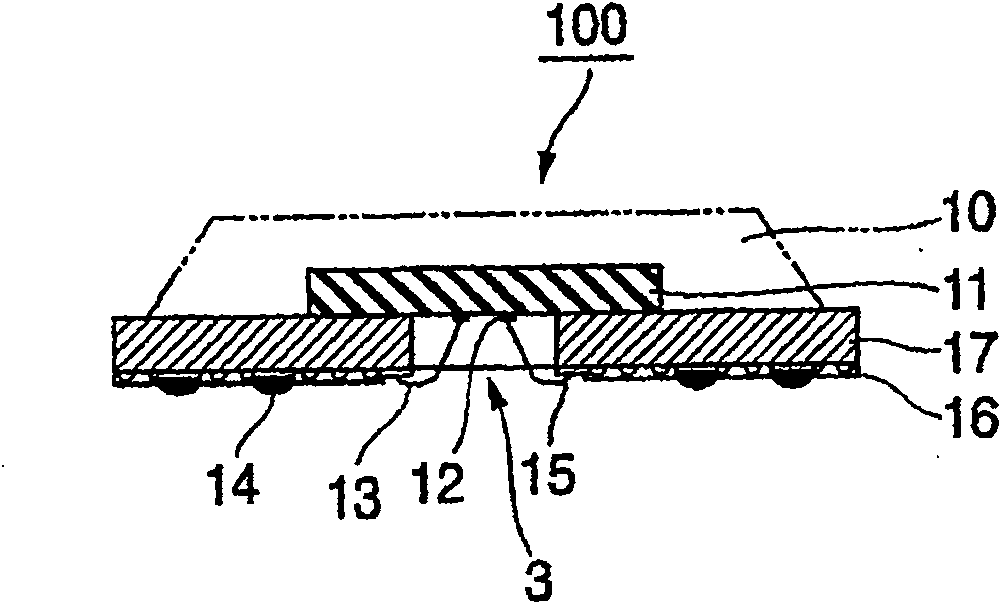

[0074] Using a 0.18mm-thick glass substrate epoxy resin copper-clad laminate with a 0.02mm-thick copper layer on one side, after laminating a photoresist on the copper layer, exposure and development are performed using a photomask To etch the copper layer to form wiring patterns and dummy patterns of various shapes and sizes.

[0075] Next, solder resist is applied, exposure and development are performed using a given mask, and Ni plating of 10 μm and Au plating of 0.7 μm are performed on the surface of the copper layer of the dummy patterns and wiring patterns that appear. Then, press working is performed using a die to form openings.

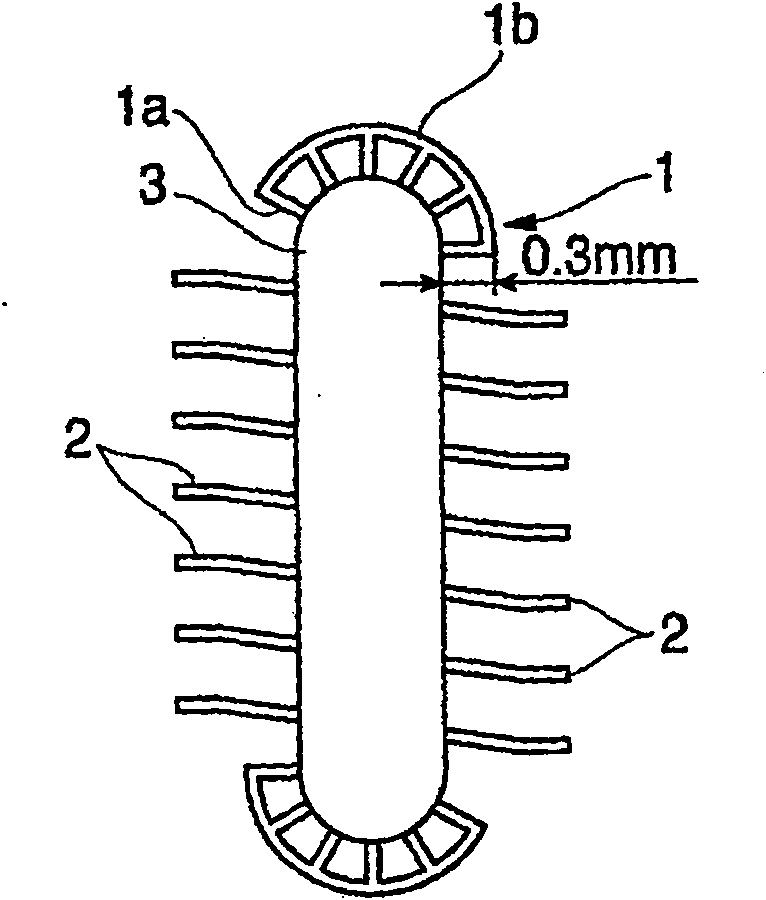

[0076] In addition, dummy patterns and wiring patterns in such as Figure 10 As shown, after forming a pattern that is electrically integrally connected on the portion that becomes the opening, press processing is used, such as figure 2 Electrical continuity is cut off as shown.

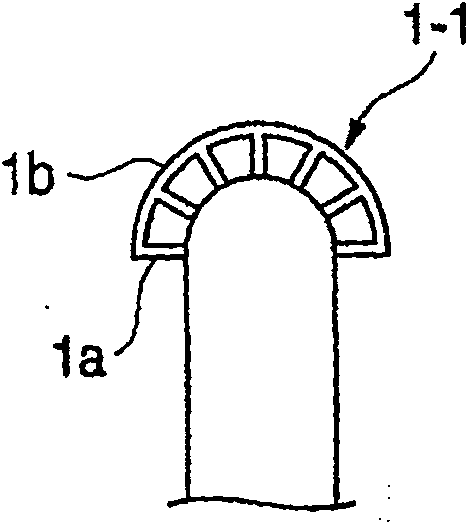

[0077] In the arc portion of the opening, from Figure 3 ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| width | aaaaa | aaaaa |

| angle | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com