Extensible solid surface antenna reflective face of shape memory material

A solid surface and memory material technology, applied in the direction of antennas, electrical components, etc., can solve the problem that the deployable antenna reflector cannot meet the requirements of large aperture and high frequency band at the same time, and achieve smooth deployment process, high reliability and high antenna gain. high effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

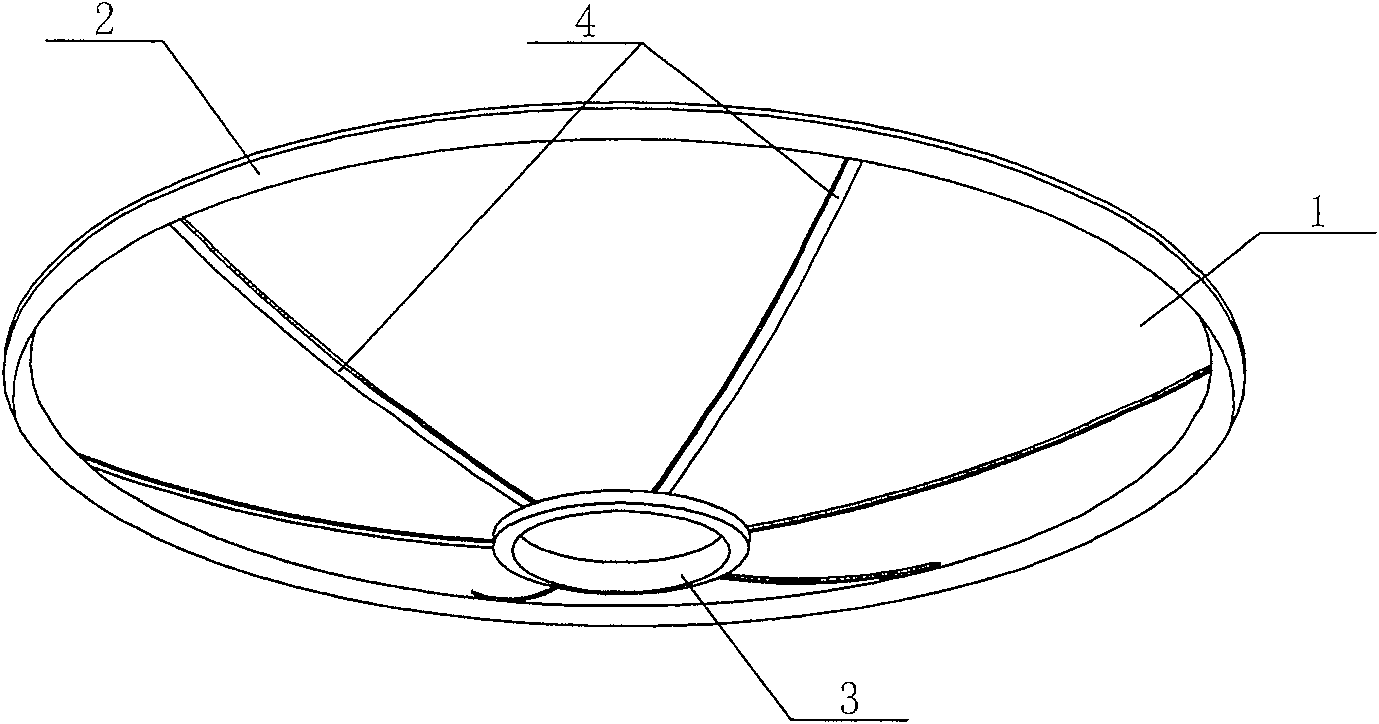

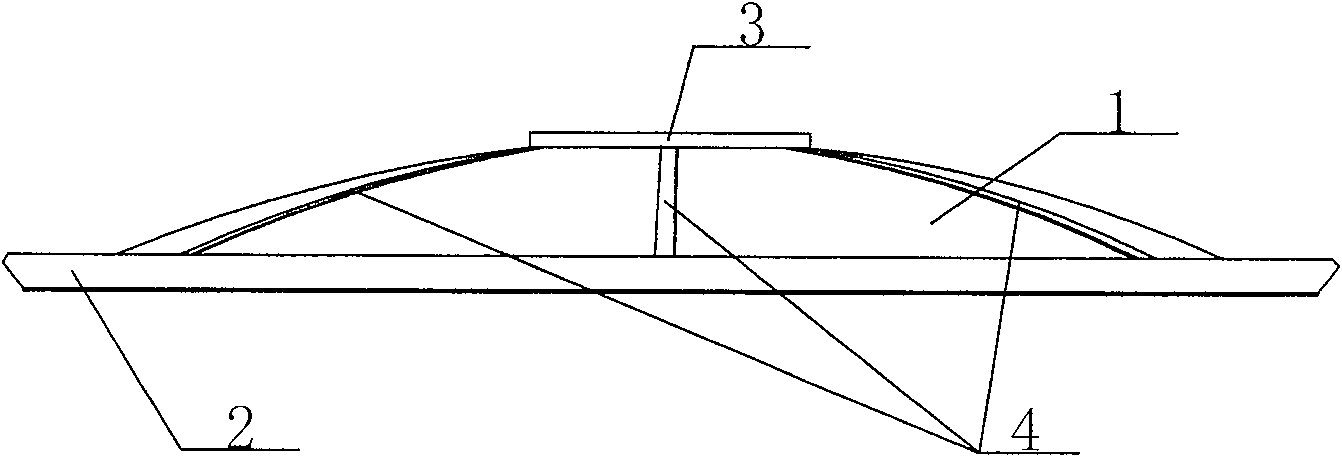

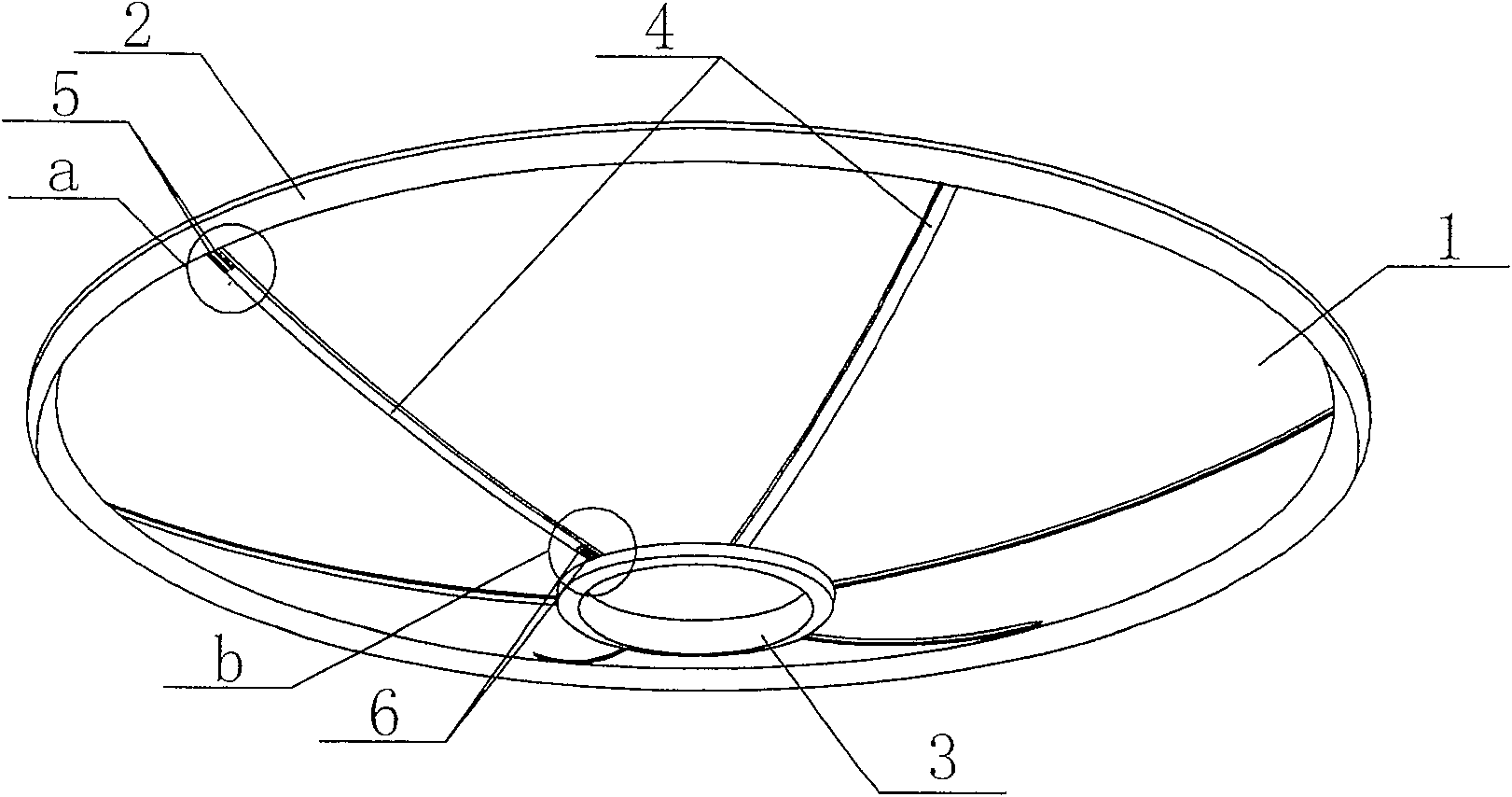

[0015] Specific implementation mode one: combine figure 1 , figure 2 Describe this embodiment. This embodiment is composed of a reflective surface body 1, a first shape memory material hoop reinforcement 2, a second shape memory material hoop reinforcement 3 and a radial reinforcement sheet 4; the reflection surface body 1 is arranged in the middle There is a parabolic shape with a circular opening, a first shape memory material hoop reinforcement 2 is fixedly connected to the upper edge of the back of the reflective surface body 1, and a second shape is fixedly connected to the lower edge of the back of the reflective surface body 1 The memory material hoop reinforcement 3, the back of the reflective surface body 1 between the first shape memory material hoop reinforcement 2 and the second shape memory material hoop reinforcement 3 is provided with radial reinforcement pieces 4 arranged in a parabolic direction; The first shape memory material hoops the reinforcement 2 and ...

specific Embodiment approach 2

[0016] Specific implementation mode two: combination figure 1 , figure 2 Describe this embodiment. The difference between this embodiment and the specific embodiment is that the thicknesses of the first shape memory material hoop reinforcement 2 and the second shape memory material hoop reinforcement 3 are respectively 0.02-80mm; other components and connection methods It is the same as the first embodiment.

specific Embodiment approach 3

[0017] Embodiment 3: The difference between this embodiment and Embodiment 2 is that the shape memory composite material of the first shape memory material hoop reinforcement 2 and the second shape memory material hoop reinforcement 3 is made of shape memory polymer material, reinforced phase material and / or resistance material; the volume content of each component material is: 5-98 parts of shape memory polymer material, 2-95 parts of reinforced phase material, and 0-100 parts of resistance heating material; other compositions and connection methods are the same as The second embodiment is the same.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| radius | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com