Method and apparatus for manufacturing packaging film stay

A film drawing wire and equipment technology, which is applied in the field of packaging film opening structure, can solve the problems of flanging, material waste, and the film cannot be cut, and achieves the effect of improving shear force, maintaining integrity, and facilitating unpacking

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

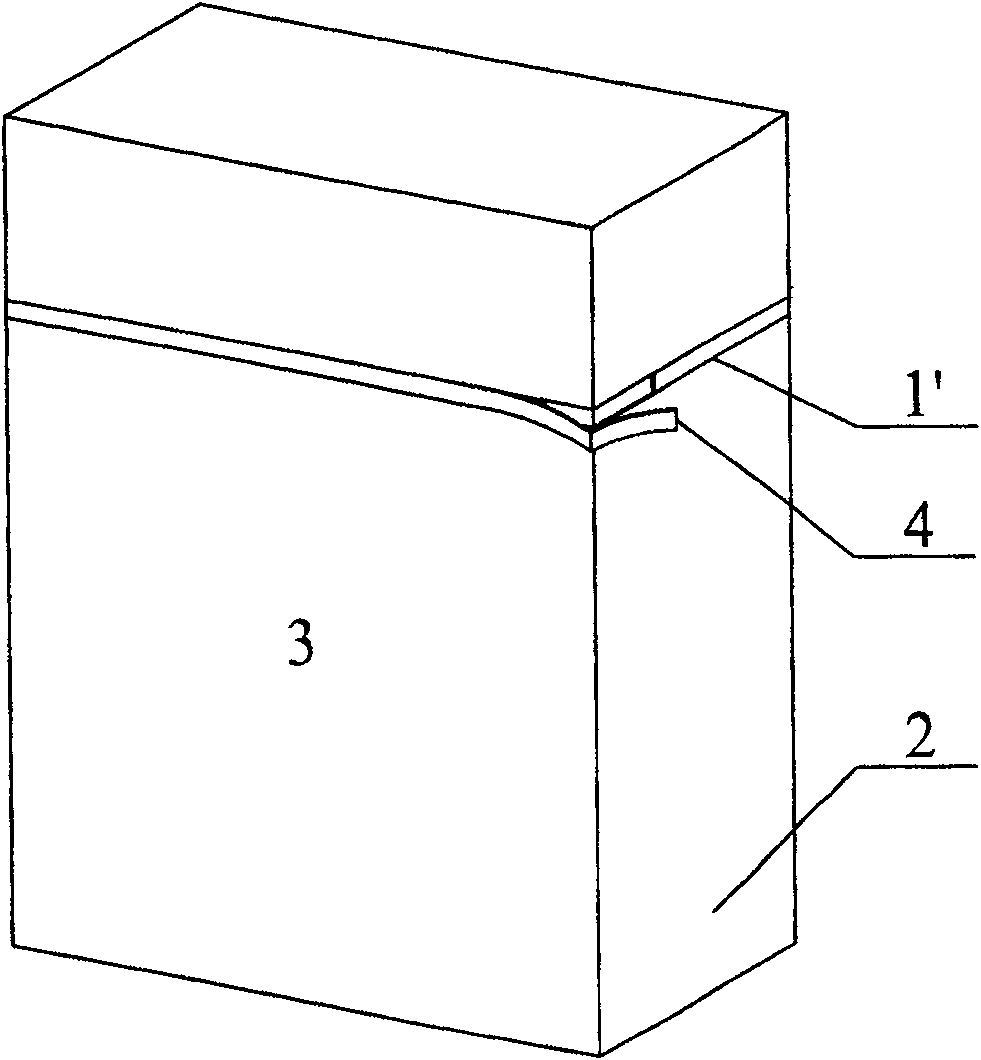

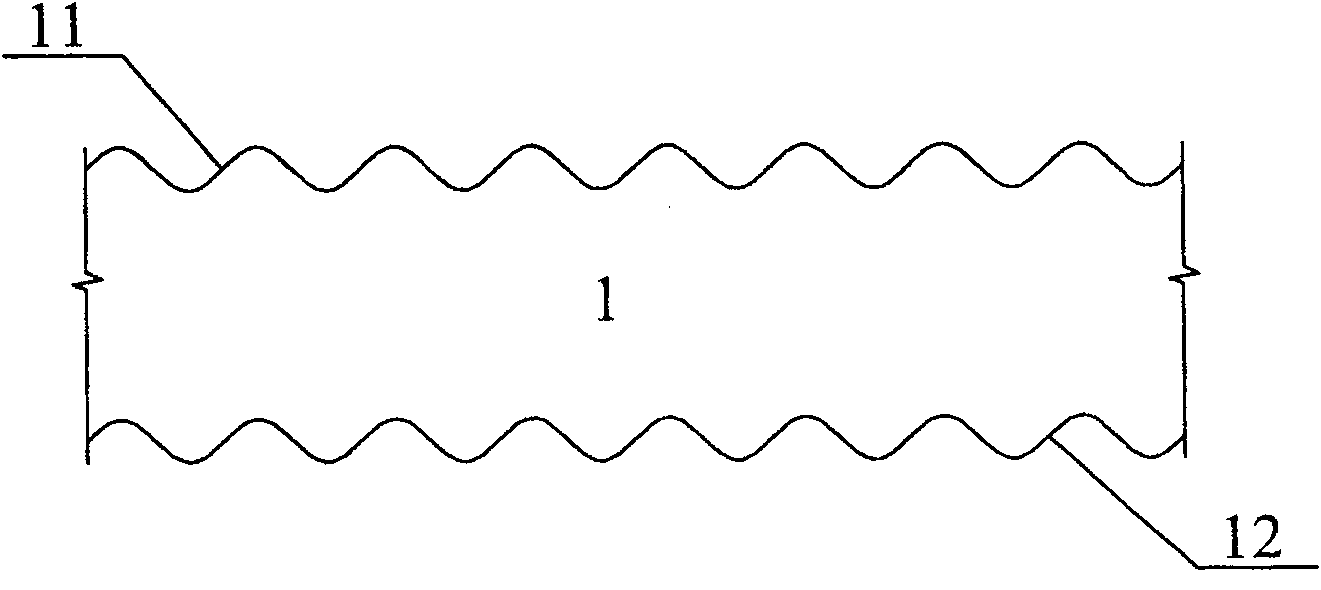

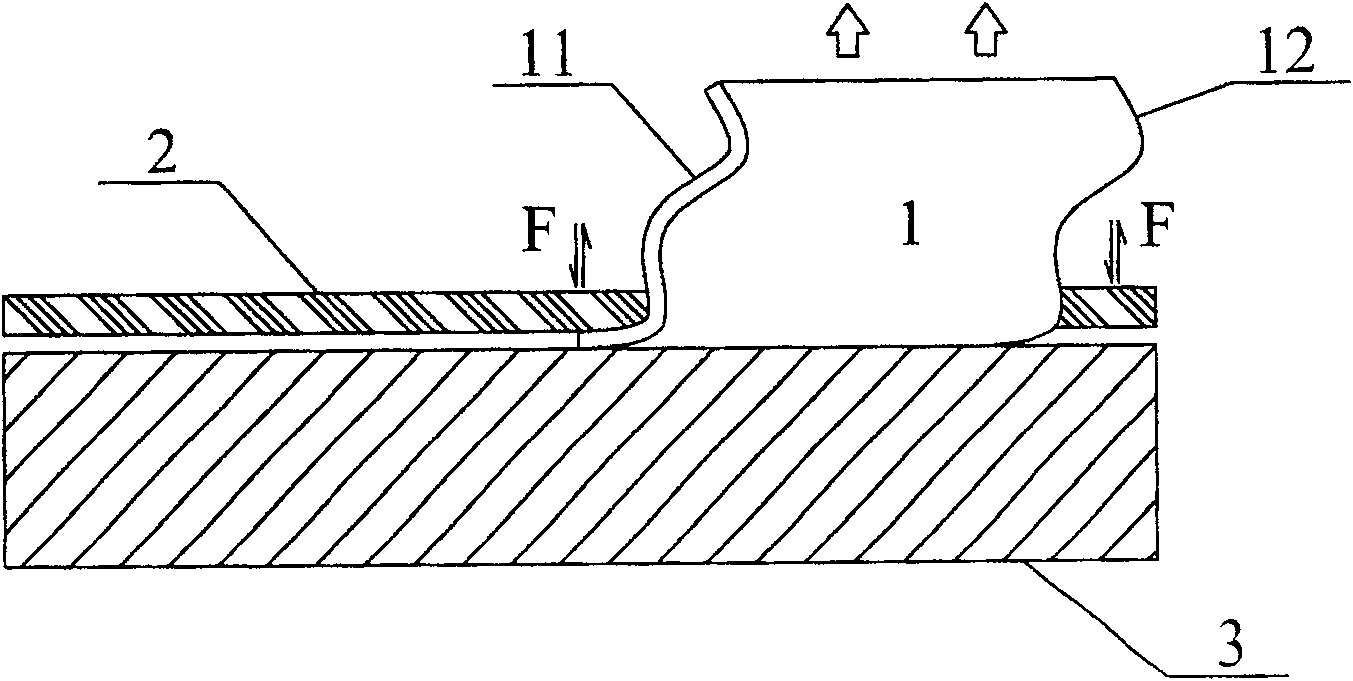

[0057] In order to overcome the above-mentioned shortcoming in the prior art, the present embodiment provides a kind of novel packaging film pull wire 1, such as Figure 2A As shown, the structure is a strip structure with a certain width, and the two sides 11 and 12 of the pull wire are in the shape of a periodically changing sinusoidal curve, and the shapes 11 and 12 on both sides correspond to the positions completely. When packaging, such as Figure 2B As shown, the pull wire 1 is embedded between the packaging film 2 and the packaging box 3 . During use, pull up the pull wire 1 along the direction perpendicular to the packaging film 2 by hand, as shown by the hollow arrow in the figure. Under the action of the pulling force, the shearing force F generated by the sides 11 and 12 of the pulling wire 1 on the film packaging is much larger than that of the existing linear pulling wire. The film package 2 can be easily pulled apart along the pull wire 1 , and the cutout of t...

Embodiment 2

[0060] Such as image 3 As shown, one side 11 of the pull wire 1 changes in a periodically changing sinusoidal curve, while the other side 12 still retains the existing straight-line structure. During use, the opening of the film packaging is in a straight line and changes in a sinusoidal curve. It has a pull cord and an opening structure different from that of Embodiment 1, and has unique characteristics on the packaging.

Embodiment 3

[0062] The shape of the two sides 11, 12 of the backguy 1 of the present embodiment is the same as that of the embodiment 1, as Figure 4 As shown, the main difference is that the phase difference between the upper and lower sides 11 and 12 is half a period. When in use, the opening of the film package is also similar to that of Example 1, which can be used as an indication of cigarettes of comparable quality.

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap