Continuous gas type baking furnace especially for rubber products

A baking furnace and gas technology, applied in the field of rubber product baking furnaces, can solve the problems of increasing the size and cost of the furnace and its accessories

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

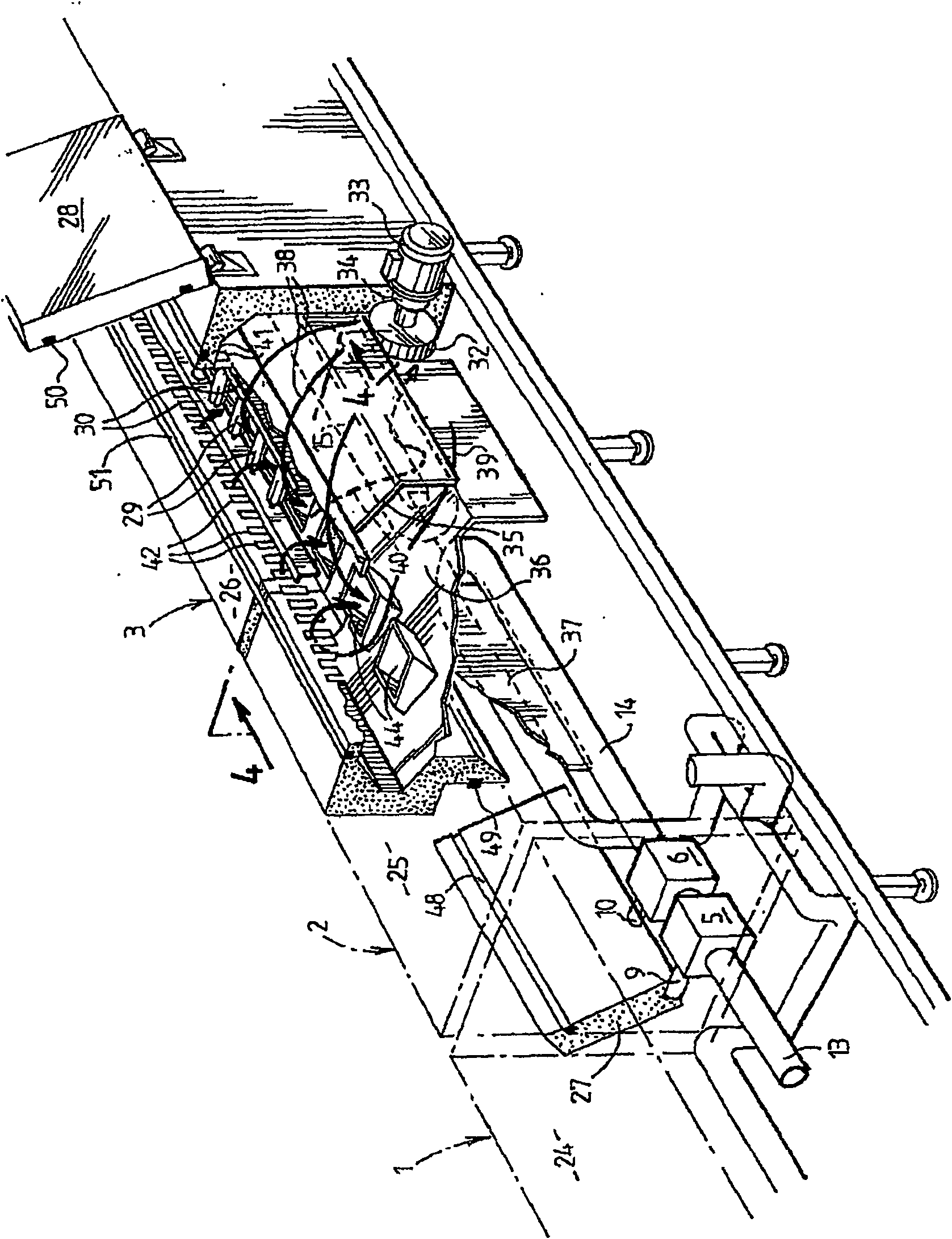

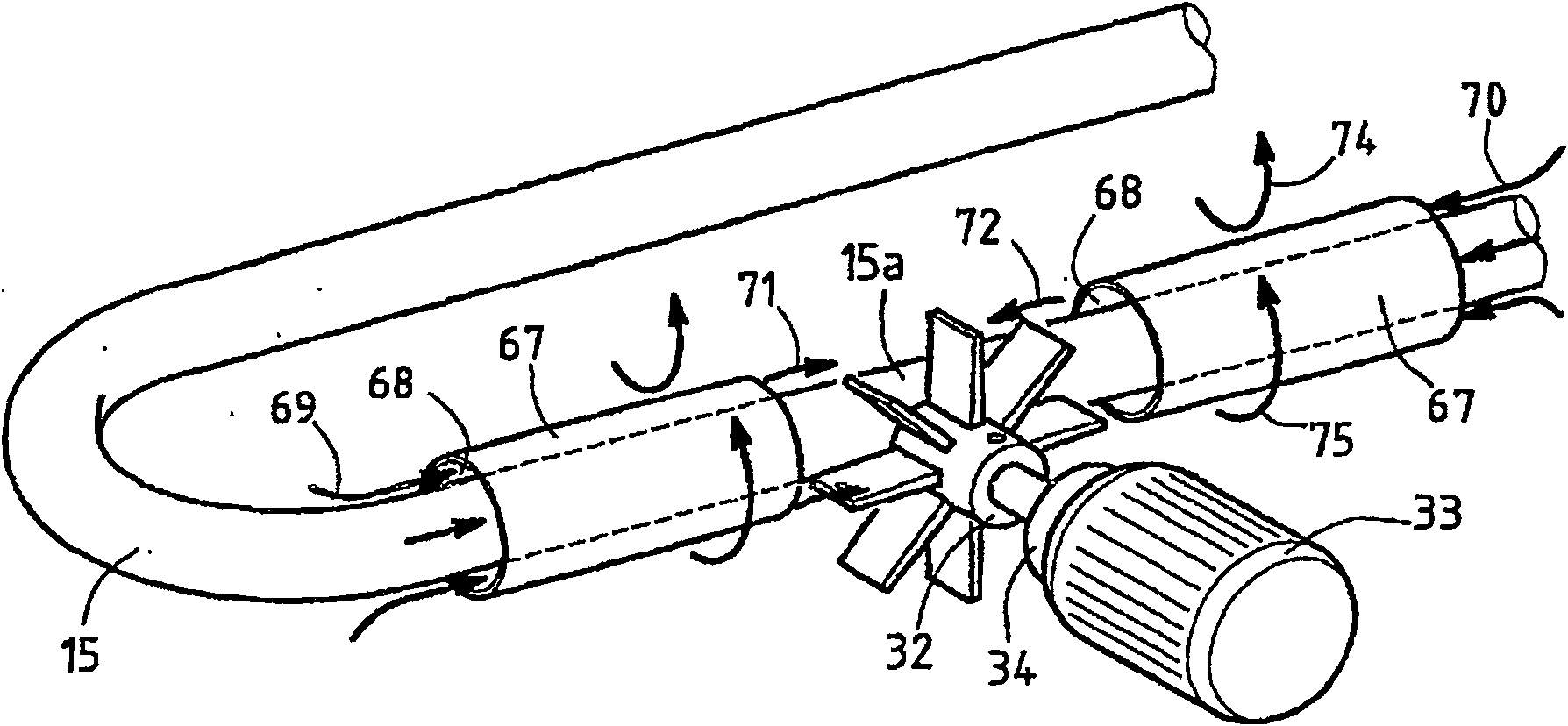

[0031] [31] The following description relates to an embodiment of the invention based on the development of the furnace described in the document EP-A-1 216 129 already mentioned. For more details concerning the characteristics and operation of the furnace, reference is usefully made to said literature. However, it is to be understood that the invention is not intended to be limited to the particular embodiments described.

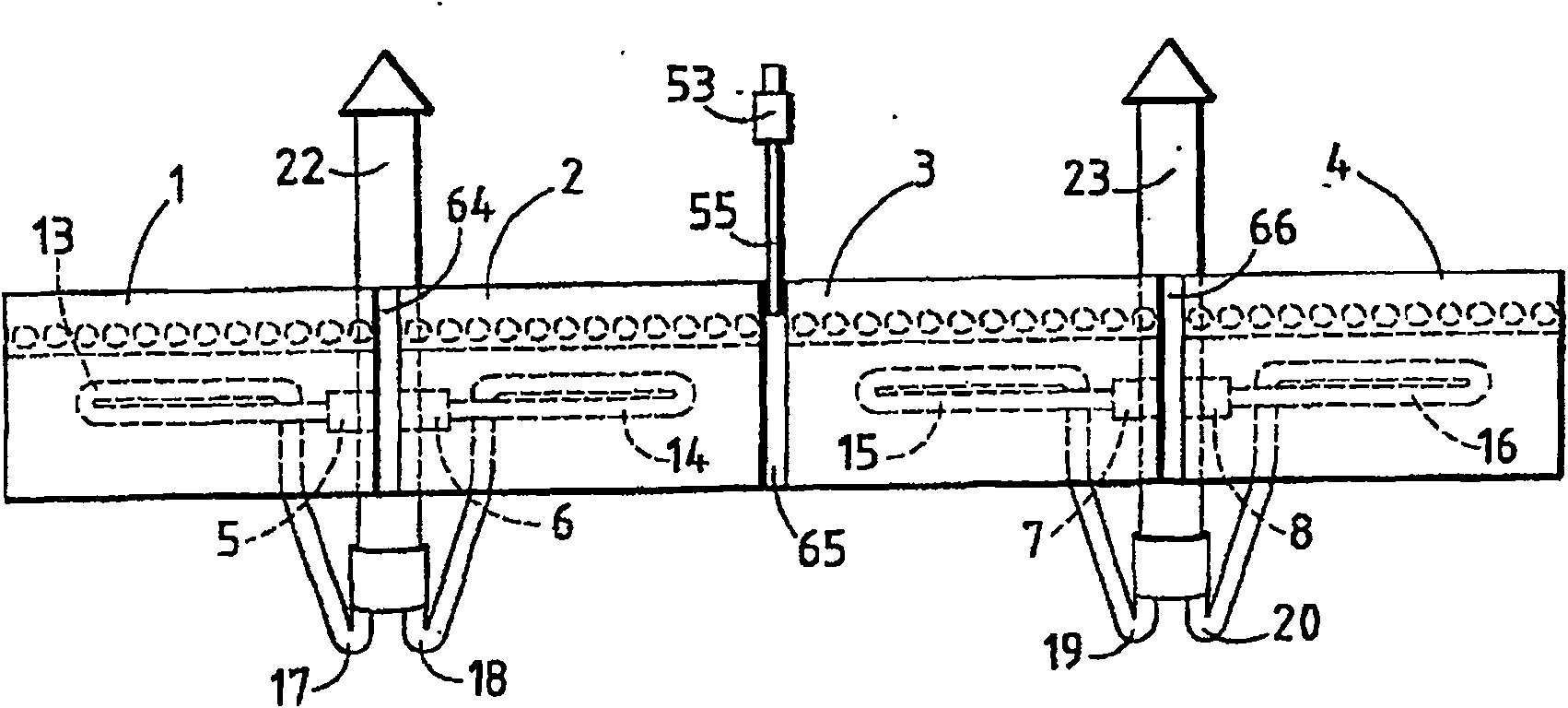

[0032] [32] in figure 1 The oven shown schematically above comprises a plurality of oven modules 1, 2, 3, 4, the number of which depends on the travel speed of the products to be baked, which is determined by the speed of the production line located upstream and The product is determined by the necessary residence time for baking.

[0033] [33] Modules 1 , 2 , 3 , 4 are connected between them by means of joints that assemble their enclosures, with suitable thermal insulation pads 64 , 65 , 66 interposed.

[0034] [34] Gas burners 5, 6, 7, 8 are connecte...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com