A pyrolysis and reduction reaction system and method for reusing laterite-nickel ore dry pellets in a flue gas waste heat furnace body

A technology of laterite nickel ore and flue gas waste heat, which is applied in the field of chemical industry and metallurgy, can solve the problem of not considering the recovery of oil and gas resources, and achieve the effect of reducing process energy consumption and cost, reducing process energy consumption and cost, and increasing by-products

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

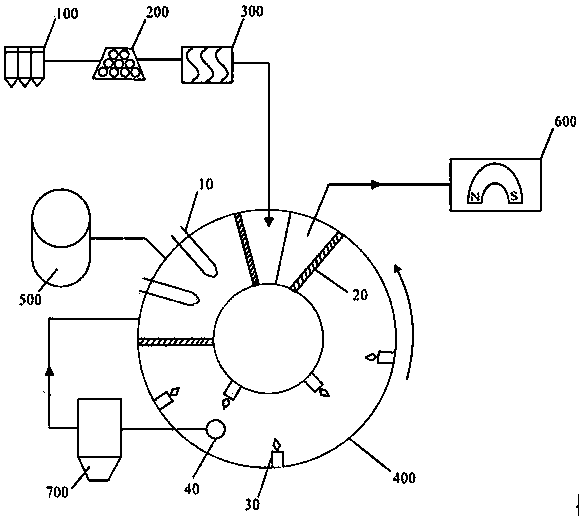

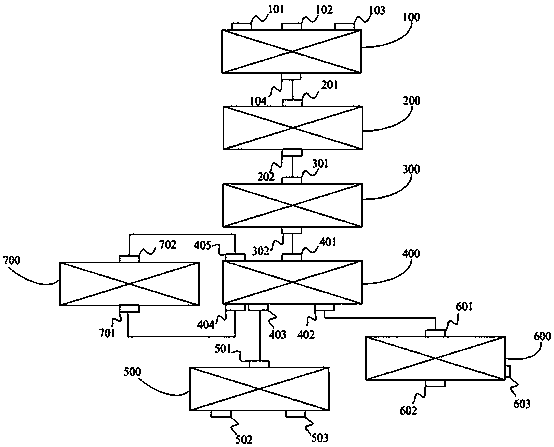

Embodiment 1

[0059] The laterite nickel ore (containing Ni 1.85%), bituminous coal (25% volatile matter) and sodium carbonate are batched and mixed in the batching device according to the mass ratio of 100:10:5 to obtain a mixed material, and the mixed material is processed in the molding device The mixed pellets are obtained by forming in a drying device, and then the mixed pellets are dried in a drying device to obtain dry pellets (water content 1.0%), and the dry pellets are pyrolyzed in a rotary hearth furnace with pyrolysis and reduction functions And reduction treatment, the included angle of the ring in the pyrolysis zone is 30º, the temperature in the pyrolysis zone is 400°C, the included angle of the ring in the reduction zone is 300º, the temperature in the reduction zone is 1000°C, the heat of the heating pipe comes from the high-temperature dedusting flue gas of the rotary hearth furnace, The obtained pyrolysis oil and gas are processed by the oil and gas recovery device to obta...

Embodiment 2

[0061] The laterite nickel ore (containing Ni 2.45%), lignite (40% volatile matter) and limestone are batched and mixed in the batching device according to the mass ratio of 100:20:15 to obtain a mixed material, and the mixed material is placed in the molding device Perform molding treatment to obtain mixed pellets, then dry the mixed pellets in a drying device to obtain dry pellets (1.5% water content), and perform pyrolysis and reduction of dry pellets in a rotary hearth furnace with pyrolysis and reduction functions For reduction treatment, the included angle of the ring in the pyrolysis zone is 60º, the temperature in the pyrolysis zone is 600°C, the included angle of the ring in the reduction zone is 270º, the temperature in the reduction zone is 1250°C, and the heat of the heating pipe comes from the high-temperature dedusting flue gas of the rotary hearth furnace. The pyrolysis oil and gas are processed by the oil and gas recovery device to obtain tar and gas, and the me...

Embodiment 3

[0063] The laterite nickel ore (containing Ni 1.12%), sub-bituminous coal (35% volatile matter) and lime are mixed and mixed in the batching device according to the mass ratio of 100:30:9 to obtain the mixed material, and the mixed material is processed in the molding device The mixed pellets are obtained by molding in a drying device, and then the mixed pellets are dried in a drying device to obtain dry pellets (water content 0.5%), and the dry pellets are pyrolyzed in a rotary hearth furnace with pyrolysis and reduction functions And reduction treatment, the included angle of the ring in the pyrolysis zone is 100º, the temperature in the pyrolysis zone is 900°C, the included angle of the ring in the reduction zone is 240º, the temperature in the reduction zone is 1400°C, the heat of the heating pipe comes from the high-temperature dedusting flue gas of the rotary hearth furnace, The obtained pyrolysis oil and gas are processed by the oil and gas recovery device to obtain tar ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com