Methods and systems for pyrolyzing biomass

A technology for biomass and pyrolysis products, applied in the chemical industry, can solve the problems of reducing the treatment cost and the large amount of catalyst, and achieve the effect of reducing the treatment cost, heating uniformly, and solving the large amount of catalyst.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

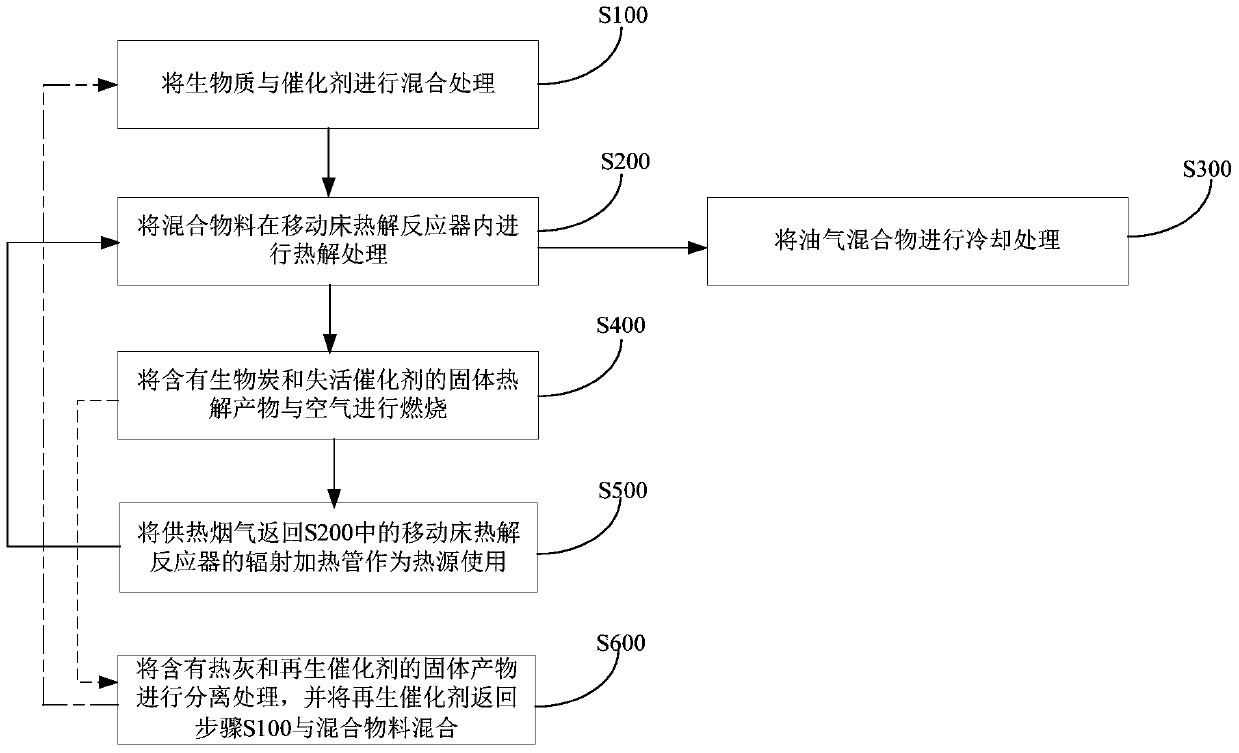

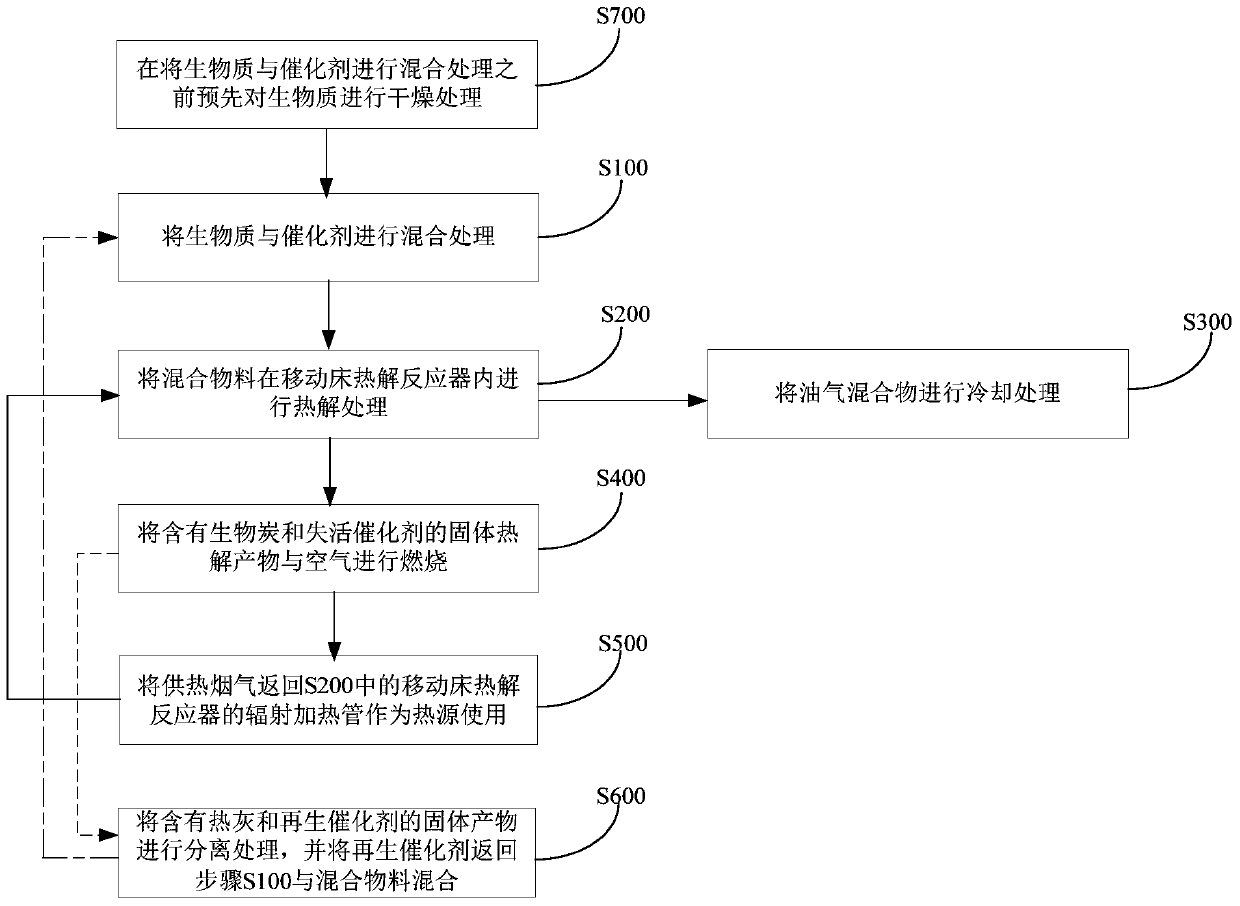

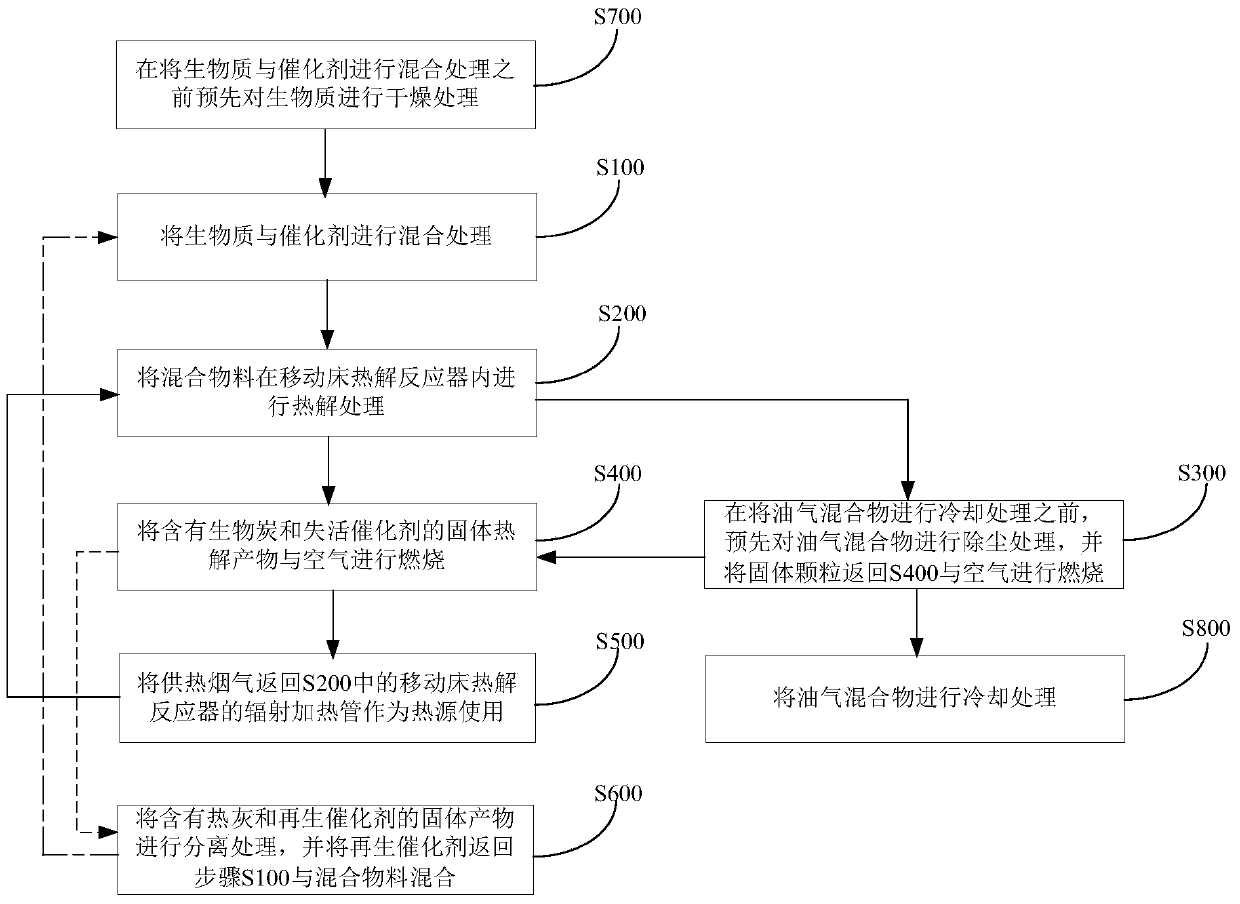

Method used

Image

Examples

Embodiment

[0106] refer to Figure 12 As shown, the pine sawdust raw material (V ad =73.88%, Q net,ar =18.41MJ / kg) stored in the raw material bin 1, transported to the drying bin 2 by belt transmission for drying treatment, reducing the moisture content in the pine wood chips, and then transported to the biomass and catalyst mixed feeding device through the biomass feeding device 3 5 is mixed with the catalyst and sent to the moving bed pyrolysis reactor 6, and the radiant heating tube 18 on the moving bed pyrolysis reactor is used to radiate and heat the mixed material to cause catalytic pyrolysis reaction (500-750°C), and the oil gas produced The mixture (500-600°C) enters the high-temperature dust collector 7 through the top pipe of the reactor for particle dust removal, and then enters the oil-gas cooler 8 to cool down. After separation, biomass oil and pyrolysis gas are obtained respectively, and the pyrolysis gas then enters the pyrolysis gas for purification The net pyrolysis ga...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com